High material utilization rate: In the traditional machining process for manufacturing intermediate casings, the material removal rate can reach more than 70%, resulting in a great waste of a large amount of titanium alloy materials (titanium alloy is a precious metal with high cost); while the SLM process only laser-melts the areas that need to be formed. The unmelted titanium alloy powder can be mixed with new powder at a ratio of 3:7 for reuse after sieving, demagnetization and performance testing, which increases the material utilization rate to more than 95% and greatly reduces the manufacturing cost.

Superior performance: After rapid laser melting and solidification of titanium alloy powder, the grains are significantly refined, forming a uniform and dense microstructure, which effectively reduces defects such as pores, cracks and segregation that are prone to occur in traditional casting processes; at the same time, the metallurgical bonding forming method makes the overall mechanical properties of the part uniform. The tensile strength, yield strength and fatigue strength are all better than those of traditional forged parts, which can withstand the harsh working conditions such as high temperature, high pressure and high-frequency vibration during the operation of aero-engines, meeting the requirements of aerospace-grade reliability.

1.3 Control of Core Technical Parameters (Key Guarantee)

The aero-engine intermediate casing is a key load-bearing component, which has extremely high requirements on forming precision and density (density needs to reach more than 99.9%, dimensional accuracy ±0.05mm). Therefore, the following core parameters must be strictly controlled during the SLM printing process to avoid defects:

• Laser parameters: The laser power is controlled at 250-300W (adapting to Ti6Al4V titanium alloy), the scanning speed is 600-800mm/s, and the spot diameter is 50-100μm to ensure that the powder is completely melted without excessive burning;

• Powder spreading parameters: The layer thickness is 20-40μm (balancing forming precision and efficiency), and the powder spreading speed is accurately matched with the scraper pressure to ensure that the powder layer is uniform and dense, avoiding unfused defects caused by uneven powder spreading;

• Atmosphere and temperature parameters: The oxygen content in the printing chamber is controlled below 100ppm to prevent oxidation of titanium alloy during high-temperature melting; the substrate is preheated to 150-200℃ to reduce the accumulation of thermal stress during part forming and avoid warping deformation;

• Scanning strategy: A zonal alternating scanning strategy is adopted to alleviate the concentration of thermal stress, reduce the residual stress inside the part, and avoid cracks during subsequent use.

II. Product Introduction: Titanium Alloy Aero-Engine Intermediate Casing (3D Printed Version)

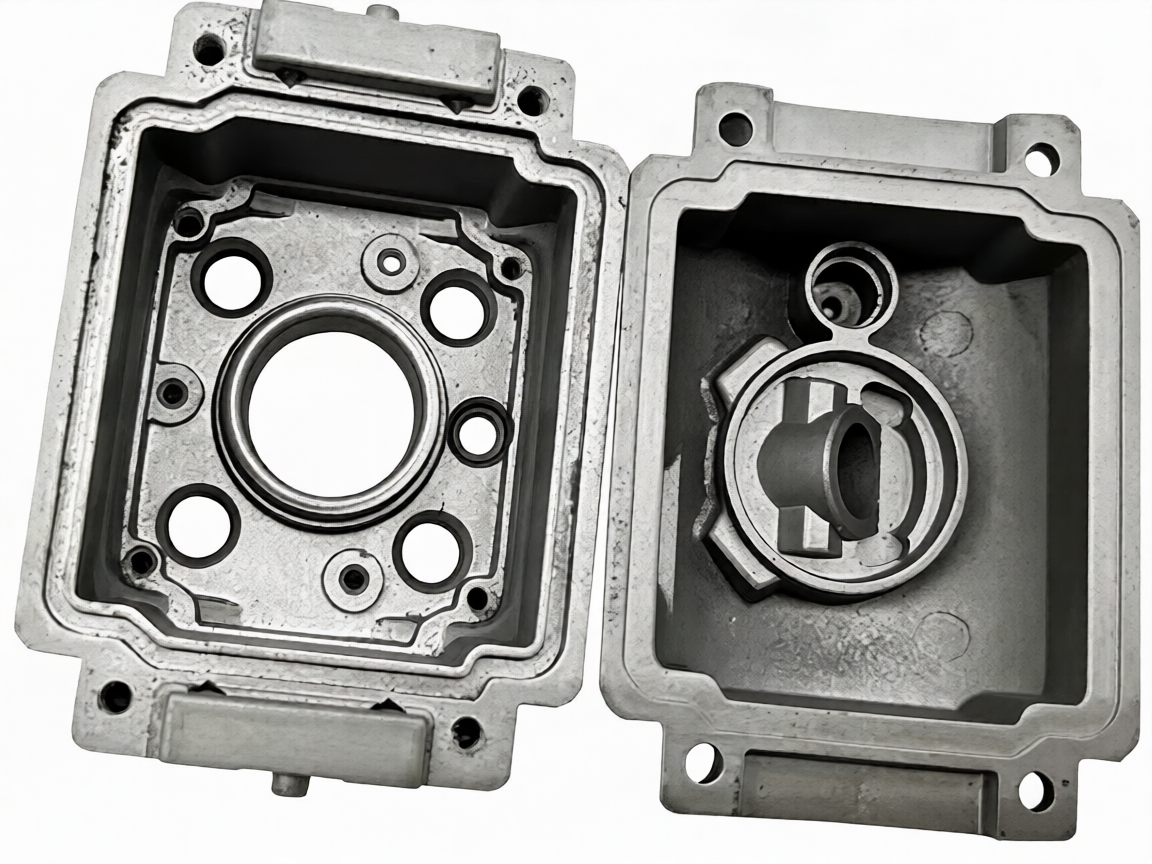

The titanium alloy aero-engine intermediate casing is the "core connecting piece and load-bearing hub" of the aero-engine. Located in the middle section of the engine, its main functions are to connect the fan module with the core engine (compressor, turbine), transmit axial and radial loads, and guide the smooth passage of air flow. Its performance directly affects the thrust, efficiency and reliability of the aero-engine. On the basis of retaining the core functions of traditional products, the intermediate casing made by metal 3D printing has achieved a triple breakthrough of "structural optimization, performance upgrading and cost reduction". The specific product characteristics are as follows:

2.1 Basic Product Specifications

• Material: Ti6Al4V titanium alloy (aerospace-grade standard) — with high strength, corrosion resistance, high temperature resistance (long-term working temperature ≤400℃), low density and other characteristics, it is the preferred material for key aero-engine components;

• Structural dimensions: Outer diameter 800-1200mm (adapting to medium-sized aero-engines), height 300-500mm, core flow channel diameter 400-600mm, wall thickness of thin-walled area 2-3mm, overall weight reduced by about 25% compared with traditional forged parts;

• Precision requirements: Dimensional tolerance ±0.05mm, surface roughness Ra≤3.2μm (key mating surfaces), density ≥99.9%, no obvious pores, cracks, unfused and other defects;

• Application scenarios: Aero-engines of medium-sized jet airliners and military fighter jets, which can adapt to the fan-core engine connection needs of different models of engines, and can be directly installed for use after performance testing.

2.2 Core Product Advantages (3D Printing Exclusive Characteristics)

Compared with the intermediate casing made by traditional casting + machining, the 3D printed version has four core competitiveness, which fits the needs of high-end aerospace manufacturing:

• Balanced lightweight and high strength: Through topological optimization design, redundant internal materials of the part are removed, and hollow lattice filling and special-shaped load-bearing rib structures are adopted. While reducing weight by 25%, the tensile strength is ≥950MPa, the yield strength is ≥860MPa, and the fatigue strength is increased by 15%-20%, which can withstand high-frequency vibration and load impact during engine operation;

• Better flow channel performance: The flow channels made by traditional processes have problems such as excessive corner fillets and rough surfaces, which affect the air flow efficiency; 3D printing can accurately form complex curved flow channels with smooth surfaces, reducing air flow resistance by more than 10% and improving the overall propulsion efficiency of the engine;

• Greatly shortened production cycle: The traditional process for manufacturing intermediate casings needs to go through mold design and manufacturing, casting, annealing, multiple machining, assembly and other links, with a production cycle of 3-6 months; 3D printing does not require molds, and it only takes 7-15 days from digital model to solid part, which greatly shortens the R&D and production cycle and adapts to the rapid iteration demand of aero-engines;

• Strong customization adaptability: According to the design needs of different models of engines, the digital model can be quickly adjusted to realize the customized production of intermediate casings without redeveloping molds, reducing R&D costs. At the same time, the flow channels and load-bearing structures can be flexibly optimized to adapt to different working conditions.

2.3 Product Performance Testing Standards

As a key aero-engine component, the 3D printed titanium alloy intermediate casing must go through multiple rounds of strict testing and fully meet the aerospace-grade standards before it can be installed. The core testing items include:

• Microscopic and density testing: A metallographic microscope is used to observe the microstructure to ensure that the grains are uniformly refined; X-ray 360° scanning is used to detect internal defects such as pores, cracks and unfusion, and the density needs to reach more than 99.9%;

• Mechanical performance testing: Sampling is carried out for tensile strength, yield strength, fatigue strength and hardness tests to ensure that all performance indicators are better than aerospace-grade standards;

• Dimensional and precision testing: A coordinate measuring machine is used to comprehensively detect the dimensional tolerance and geometric tolerance of the part to ensure that the precision of the key mating surfaces meets the standard (±0.05mm);

• Surface quality testing: Fluorescence testing is used to check for invisible microcracks on the part surface. The key mating surfaces need to be polished to achieve a surface roughness of Ra≤3.2μm.

III. Complete Manufacturing Steps: From Digital Model to Aerospace-Grade Finished Product (SLM Process Full Flow)

Manufacturing titanium alloy aero-engine intermediate casings by metal 3D printing is a rigorous systematic project, which needs to go through four stages: "preliminary preparation - printing forming - post-processing - inspection and acceptance". The operation details of each stage directly affect the final performance and precision of the product, and the whole process follows aerospace-grade manufacturing standards. The complete steps are as follows:

Stage 1: Preliminary Preparation (Core: Accurately Grasp the Digital and Material Basis)

Preliminary preparation is the basis for avoiding printing defects and ensuring product quality. It mainly includes three links: digital model design and optimization, titanium alloy powder pretreatment, and equipment commissioning, which takes about 2-3 days.

Step 1: Digital Model Design and Optimization

1. Use professional design software such as CAD and Solidworks to design the 3D digital model of the intermediate casing according to the assembly requirements of the aero-engine, and clarify the size and precision requirements of key structures such as flow channels, load-bearing ribs and connection interfaces;

2. Model optimization (core step): Combine the characteristics of the SLM process to perform topological optimization on the 3D model, remove redundant internal materials, design hollow lattice filling structures, and achieve a balance between lightweight and high strength; at the same time, optimize the model orientation to minimize the use of support structures. The important force-bearing surfaces should avoid forming a 45° angle with the substrate to reduce the step effect;

3. Slicing processing: Import the optimized 3D model into special pre-processing software for metal 3D printing (such as Polydevs) for slicing planning, cut the model into thin layers of 20-40μm thick, and generate laser scanning paths at the same time, set the scanning strategy (zonal alternating scanning) to ensure that the melting range of each layer accurately matches the designed shape;

4. Support design: For the overhanging structures and thin-walled areas of the model, design degradable or easy-to-remove support structures (using the same titanium alloy powder as the part). The function of the support is to fix the part, disperse thermal stress, and prevent warping and deformation during the printing process. The support design must balance the fixing effect and the convenience of subsequent removal.

Step 2: Titanium Alloy Powder Pretreatment

1. Powder selection: Select aerospace-grade Ti6Al4V titanium alloy powder. The powder must meet strict physical and chemical requirements—sphericity ≥95%, particle size distribution controlled at 15-45μm, oxygen content ≤0.1%, purity ≥99.9% to ensure the fluidity and melting uniformity of the powder;

2. Powder pretreatment: Before using new powder, put it into a vacuum drying oven and dry it at 120-150℃ for 2-3 hours to remove the moisture adsorbed on the powder surface and prevent pores during printing; if using recycled old powder, it must first go through sieving and demagnetization to remove impurities and oxidized particles, then perform performance testing. After passing the test, mix it with new powder at a ratio of 3:7 for reuse to ensure stable powder performance;

3. Powder loading: Uniformly load the pretreated titanium alloy powder into the powder silo of the metal 3D printer to ensure that the powder silo is free of impurities and moisture. At the same time, check the fluency of the powder feeding mechanism to avoid powder jamming and leakage during powder spreading.

Step 3: Equipment Commissioning and Parameter Setting

1. Equipment selection: Select an industrial-grade SLM metal 3D printer (such as Plasmas BLT-S1500, suitable for forming large-size complex parts). This equipment has a multi-laser scanning function, which can improve printing efficiency and forming stability;

2. Equipment commissioning: Check the laser power, galvanometer system precision, flatness of the powder spreading mechanism (scraper), calibrate the levelness of the forming platform, and ensure that the equipment operates normally;

3. Parameter setting: According to the characteristics of Ti6Al4V titanium alloy, set the core printing parameters—laser power 250W, scanning speed 700mm/s, layer thickness 30μm, scanning interval 100μm; at the same time, set the chamber atmosphere parameters, fill the printing chamber with argon, reduce the oxygen content to below 100ppm, and prevent high-temperature oxidation of titanium alloy; set the substrate preheating temperature to 180℃ to reduce thermal stress accumulation.

Stage 2: Printing Forming (Core: Accurately Control the Layer-by-Layer Melting Process)

Printing forming is the core link of converting the digital model into a solid part. The whole process is automated without manual intervention, but the operation status of the equipment must be monitored in real time to avoid printing defects. It takes about 5-10 days (adjusted according to the part size).

Step 1: Platform and Powder Initialization

Install the pretreated substrate (Ti6Al4V titanium alloy substrate, consistent with the part material to ensure tight metallurgical bonding) on the forming platform and fix it firmly; start the powder spreading mechanism, and the scraper uniformly spreads the titanium alloy powder in the powder silo on the substrate to form the first powder layer (thickness 30μm), ensuring that the powder layer is uniform and dense without gaps or protrusions.

Step 2: Layer-by-Layer Melting and Deposition

1. Start the laser, selectively scan the first powder layer according to the scanning path generated by the pre-processing software. The laser spot is focused on the powder surface, so that the powder in the scanning area is quickly melted to form a molten pool, which then solidifies rapidly to form the first solid structure;

2. After the first layer is printed, the forming platform automatically descends by one layer thickness (30μm), and the powder spreading mechanism spreads a new powder layer again, repeating the process of "scanning - melting - solidification" to form layer by layer;

3. During the printing process, through the real-time monitoring system of the equipment (molten pool monitoring system, infrared thermal imager), observe the molten pool state, temperature distribution and powder spreading situation in real time. If abnormalities such as unstable molten pool and uneven powder spreading occur, the equipment will automatically alarm and adjust parameters to avoid defects such as unfusion, pores and warping;

4. For the complex flow channels and thin-walled areas of the intermediate casing, adopt slow scanning and multiple scanning methods to ensure complete melting of the powder and improve forming precision and structural density.

Step 3: Printing Completion and Cooling

1. When all layers are printed, the equipment automatically stops the laser and the powder spreading mechanism, maintains the argon atmosphere in the printing chamber, and allows the part to cool naturally to room temperature under the protection of inert gas (cooling time is about 24-48 hours);

2. It is strictly forbidden to take out the part immediately after printing to avoid quenching effect caused by rapid cooling, which may lead to cracks, deformation and other defects of the part, and ensure that the internal thermal stress is fully released.

Stage 3: Post-Processing (Core: Eliminate Defects, Improve Performance and Precision)

The newly printed intermediate casing (called "blank part") has excess powder attached to the surface, support structures, residual stress, and its surface roughness and dimensional precision do not meet the service requirements. It needs to go through a series of post-processing procedures, which takes about 2-3 days. Only after post-processing can the part enter the inspection link.

Step 1: Cleaning of Excess Powder

1. Open the printing chamber, take out the substrate with the blank part, and use a high-pressure argon spray gun to uniformly blow off the excess titanium alloy powder on the part surface, inside the flow channel and in the gaps of the support structure to ensure that the powder is cleaned;

2. Collect the cleaned excess powder, perform sieving, demagnetization and drying treatment, and use it as recycled powder mixed with new powder after passing the test to improve material utilization rate.

Step 2: Removal of Support Structures

1. Use wire cutting technology to separate the blank part from the substrate. During the cutting process, the cutting speed and temperature must be controlled to avoid damaging the part surface and internal structure;

2. For the support residues on the part surface, adopt a combination of mechanical grinding (sandpaper grinding, grinder grinding) and electrochemical machining to remove the support residues, ensuring that the part surface is flat without protrusions or burrs; for the complex support residues inside the flow channel, adopt chemical dissolution to remove them to avoid damaging the flow channel surface.

Step 3: Heat Treatment (Eliminate Residual Stress and Improve Mechanical Properties)

1. Put the part with the support removed into a vacuum annealing furnace for stress annealing treatment, set the annealing temperature to 800-850℃, keep it warm for 2-4 hours, then cool it slowly to room temperature. Through annealing treatment, the residual stress accumulated during part forming is eliminated, and subsequent deformation of the part is prevented;

2. According to the characteristics of Ti6Al4V titanium alloy, additional solution aging treatment is performed: set the solution temperature to 950℃, keep it warm for 1 hour, then cool it rapidly, and then perform aging treatment (temperature 500℃, keep it warm for 4 hours). Through solution aging treatment, the grains are refined, the tensile strength, yield strength and fatigue strength of the part are improved, and the mechanical properties meet the aerospace-grade standards.

Step 4: Surface and Dimensional Finishing

1. Surface treatment: Polish the key mating surfaces of the part (connection surfaces with the fan and core engine) by combining mechanical polishing and chemical polishing,

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.