Abstract

The evolution of the smart thermostat from a simple temperature regulator to the central nervous system of a home's HVAC and environmental management network represents a significant leap in consumer technology. This transformation is underpinned by advanced manufacturing techniques capable of producing devices that are not only intelligent and connected but also physically robust, aesthetically refined, and mechanically precise. Computer Numerical Control (CNC) machining stands as a foundational pillar in this manufacturing ecosystem, bridging the gap between complex electronic design and tangible, high-reliability hardware. This paper delves into the multifaceted applications of CNC machining across the entire product lifecycle of a modern smart thermostat, from rapid prototyping and tooling to the production of critical end-use components. It explores the technical advantages, material considerations, and economic rationale that make CNC technology indispensable for producing these sophisticated nodes of the smart home.

1. Introduction: The Smart Thermostat as a Precision Electro-Mechanical System

A contemporary smart thermostat is a confluence of multiple engineering disciplines. At its core, it houses a microprocessor, wireless communication modules (Wi-Fi, Zigbee, Bluetooth), environmental sensors (temperature, humidity, ambient light, proximity), a relay control board for HVAC systems, and often a high-resolution touchscreen display. This dense packaging of electronics must be housed within a consumer-friendly device that mounts neatly on a wall, operates silently, withstands years of daily interaction, and provides accurate environmental readings. The mechanical housing is therefore not merely a "box" but an integrated system responsible for thermal management, sensor calibration, user interface (UI) integrity, EMI/RFI shielding, and aesthetic appeal. Meeting these concurrent demands for precision, durability, and complexity is where subtractive manufacturing, particularly CNC machining, excels.

2. Material Science and Selection for CNC Machining in Thermostats

The choice of material is paramount and varies by component function, directly influencing the CNC process parameters.

* Enclosures & Faceplates: CNC milling primarily uses engineering-grade thermoplastics like Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS), or PC-ABS blends. These offer an optimal balance of impact resistance, dimensional stability, excellent surface finish for painting or texture-matching, and flame-retardant properties. For premium models, aluminum alloys (e.g., 6061, 5052) are chosen for their superior heat dissipation, structural rigidity, and high-end metallic finish achievable through machining and subsequent anodizing.

* Internal Structural Components: Aluminum remains the workhorse for brackets, frames, and heat sinks due to its favorable strength-to-weight ratio and thermal conductivity. For electrically insulating components, PEEK (Polyether Ether Ketone) or advanced nylons may be CNC machined for their high temperature resistance and stability.

* Sensor Modules and Precision Parts: Brass or stainless steel may be used for critical sensor housings or connector ports where corrosion resistance, hermetic sealing, or specific thermal properties are required.

3. Comprehensive Applications of CNC Machining in Thermostat Manufacturing

For low to medium production volumes, or for components where injection molding is impractical, CNC machining is used directly for manufacturing final parts.

3.1. Prototyping and Design Validation

Before mass-production tooling is committed, CNC machining is the gold standard for creating functional prototypes.

* Iterative Design: Engineers can quickly produce a fully operational housing from a solid block of material, allowing for hands-on testing of fit (PCB, display, buttons), form factor, wall-mounting mechanics, and user ergonomics. Multiple design iterations can be machined within days, accelerating the development cycle.

* Real-World Testing: CNC prototypes in final intended materials can undergo rigorous environmental testing (thermal cycling, humidity, UV exposure) and mechanical testing (drop, impact, button actuation life). This provides invaluable data that 3D-printed prototypes, with different material properties, cannot reliably offer.

* Market and Compliance Testing: Prototypes are used for FCC/CE certification (EMI testing), interoperability testing with HVAC systems, and focus group evaluations for user experience.

3.2. Production of End-Use Components

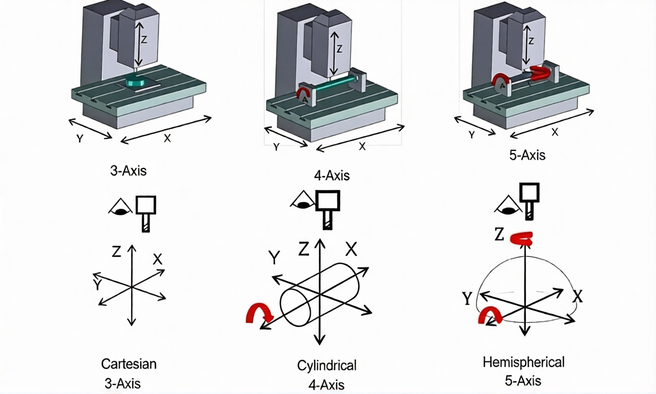

This is the most visible application. A 3-axis or, more commonly, a 4/5-axis CNC milling center performs a series of operations on a material blank:

* Contouring: Creates the smooth, curved, or angled exterior surfaces that define the product's industrial design.

* Pocketing: Machines out the large internal cavity to precisely accommodate the PCB stack-up, battery compartment, and wire routing.

* Hole Making: Drills and bores a multitude of precision holes:

* Display Aperture: Creates a perfectly dimensioned and smooth-edged window for the touchscreen, often with a recessed lip for adhesive bonding or a gasket seal.

* Ventilation Grilles: Machines an array of small, consistent slots or holes on the top, bottom, or sides. These are critical for allowing ambient air to flow over the internal temperature and humidity sensors without creating drafts that skew readings. The geometry of these vents is often optimized through computational fluid dynamics (CFD) and requires CNC precision to replicate.

* Mounting & Assembly Features: Creates pilot holes for wall screws, precise alignment pins for the rear plate, and hidden snap-fit or screw boss features for joining the front and rear housings.

* Surface Finishing: The CNC toolpath can create specific surface textures (e.g., a matte bead-blasted look on aluminum, or a light texture on plastic). This eliminates or reduces post-processing, providing a part-ready finish directly from the machine.

3.3. Manufacturing of Production Tooling

CNC machining is the primary method for creating the molds (tools) for injection molding. When a smart thermostat model is slated for high-volume production (hundreds of thousands of units), the plastic enclosures will transition to injection molding for per-part cost efficiency.

* Mold Cavities and Cores: The intricate, negative geometry of the thermostat housing is directly machined into hardened tool steel or aluminum blocks using high-speed, multi-axis CNC machines. The precision of this CNC work directly determines the quality, dimensional accuracy, and surface finish of every molded part produced.

* Inserts and Action Features: Complex mold features like sliding shut-offs for vent holes, lifters for undercuts, and conformal cooling channels are all manufactured via CNC machining. This enables the production of the complex, one-piece plastic housings that characterize modern devices.

4. Technical and Economic Advantages of CNC for Smart Thermostat Production

* Unmatched Precision and Repeatability: CNC machines consistently hold tolerances within ±0.025mm or tighter. This is non-negotiable for sensor alignment, display fit, and ensuring waterproof/dustproof ratings (e.g., IP ratings) are achieved through precise mating of parts.

* Design Freedom and Complexity: 5-axis CNC machining can create organic shapes, deep undercuts, and complex internal channels that would be impossible or prohibitively expensive to achieve with other manufacturing methods or to demold in injection molding.

* Speed and Flexibility: From CAD model to finished part is exceptionally fast, especially for prototypes and bridge production. Design changes are implemented simply by modifying the digital toolpath, with no physical tooling alterations required until the final mold is made.

* Superior Material Properties: CNC parts are made from solid stock, resulting in isotropic material properties that are often superior to the anisotropic nature of molded or 3D-printed parts. This means better strength, thermal performance, and long-term dimensional stability.

* Scalability and Bridge Production: CNC machining provides a seamless pathway from prototype to market launch. Companies can use CNC to produce the first several thousand units for market entry while the high-cost injection molds are being manufactured and qualified, mitigating time-to-market risk.

5. Future Trends and Convergence with Additive Manufacturing

The future will see further integration of CNC within a hybrid manufacturing workflow:

* CNC for Final Finishing: Additive Manufacturing (3D Printing) may be used to create near-net-shape complex structures (e.g., lattice-filled internal brackets for weight reduction), which are then finished to critical dimensions using CNC machining for precision interfaces.

* Micro-Machining: As thermostats incorporate more miniature sensors (e.g., for VOC detection), micro-CNC capabilities will be required to machine tiny, precise ports and chambers.

* Smart Machining and AI: Integration of in-process monitoring and adaptive control will further enhance quality assurance, automatically compensating for tool wear during long production runs of critical components.

6. Conclusion

The smart thermostat is a paradigm of modern consumer electronics, where intelligence is inextricably linked to physical form and function. CNC machining is not merely a manufacturing option but a critical enabling technology throughout its creation. It provides the essential bridge between digital design and physical reality, ensuring that the sophisticated algorithms and connectivity features are housed within a device that is precise, reliable, durable, and aesthetically worthy of a central place in the modern home. From the first functional prototype to the molds for mass production and the manufacture of high-precision internal components, CNC machining’s versatility, precision, and material excellence make it an indispensable partner in the ongoing innovation and production of smart home ecosystems. As these devices continue to evolve towards greater integration and capability, the demands on their physical manufacture will only increase, securing the central role of advanced subtractive manufacturing techniques for the foreseeable future.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.