In the fast-paced world of modern manufacturing, CNC Machining (Computer Numerical Control Machining) stands as a cornerstone technology that bridges design concepts with high-precision physical components. As a professional CNC Machining service provider, we leverage this automated, high-accuracy manufacturing process to transform raw materials into custom parts and components that meet the stringent demands of diverse industries. This article aims to comprehensively unpack what CNC Machining is, its core processes, key advantages, industry applications, and our commitment to delivering exceptional service.

Core Definition of CNC Machining

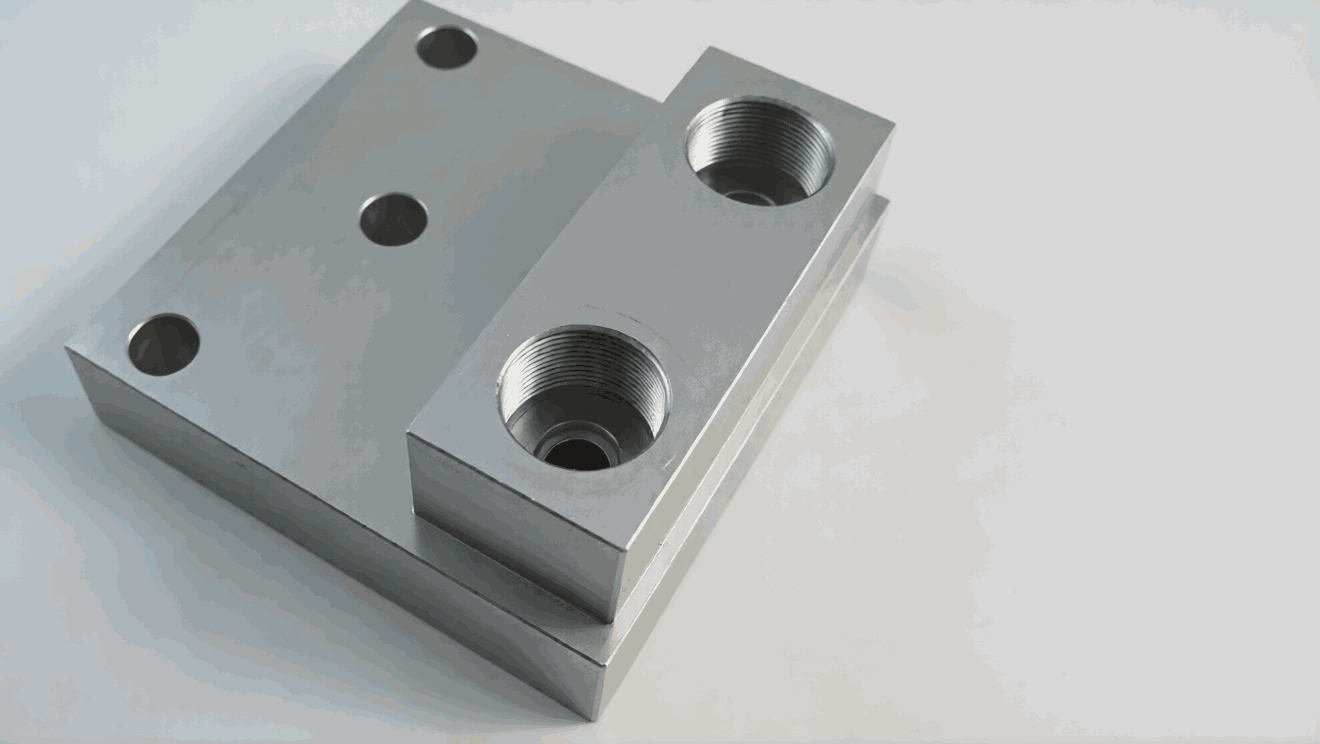

At its essence, CNC Machining is a subtractive manufacturing technique that uses pre-programmed computer software to control the movement of machine tools. Unlike traditional manual machining, which relies heavily on the skill and experience of operators, CNC Machining automates cutting, drilling, milling, turning, and other shaping processes with unparalleled consistency and precision. The core logic lies in translating 3D design drawings into machine-readable G-code instructions, which guide the toolpath and cutting parameters to remove excess material from a workpiece, ultimately forming the desired shape, size, and surface quality.

This automation not only eliminates human error but also enables the production of complex geometric parts that are difficult or impossible to achieve with manual operations. From simple flat components to intricate curved surfaces, CNC Machining delivers repeatable results with tight tolerances, making it indispensable in high-precision manufacturing scenarios.

Our Core CNC Machining Service Process

To ensure every project meets or exceeds client expectations, we adhere to a rigorous, closed-loop service process covering six key stages. Each stage is managed by professional engineers and technicians, with strict quality control measures in place.

1. Design & Programming: From Blueprint to Machine Instructions

The foundation of successful CNC Machining lies in precise design and programming. Our team works closely with clients to convert their design requirements into actionable manufacturing plans:

• 3D Modeling (CAD): We use industry-leading CAD software (such as SolidWorks, AutoCAD, and Fusion 360) to create detailed 3D models of the part, marking critical parameters including dimensions, tolerances, and surface roughness. The final model is exported in universal formats (e.g., .step, .igs) for seamless subsequent processing.

• Toolpath Planning & G-Code Generation (CAM): The 3D model is imported into CAM software (e.g., Mastercam, UG NX) to generate optimized toolpaths. Our engineers carefully set key parameters such as spindle speed (e.g., 1000r/min), feed rate (e.g., 200mm/min), cutting depth (e.g., 0.5mm), and tool selection (e.g., end mills, drills) based on the material and part requirements. The final output is a G-code file (e.g., .txt, .nc), the "language" that controls the CNC machine.

2. Material Preparation: Quality from the Start

We understand that the quality of raw materials directly determines the performance of the final product. Our material preparation process focuses on selection and strict incoming inspection:

• Material Selection: We support a wide range of materials, including metals (aluminum alloy, stainless steel, carbon steel, titanium alloy), plastics (ABS, PC, PEEK), and composites (carbon fiber, glass fiber). The selection is based on the client’s functional requirements—for example, aluminum alloy for lightweight components, stainless steel for corrosion resistance, and titanium alloy for high-strength aerospace parts.

• Incoming Quality Control (IQC): All raw materials undergo rigorous testing using advanced equipment. We verify chemical composition (via spectrometers), mechanical properties (via universal testing machines), and surface quality (via visual inspection and surface analyzers) to ensure compliance with industry standards and client specifications.

3. Machining Setup: Precision Preparation

Proper setup is critical to achieving consistent precision. Our technicians follow strict protocols to prepare the machine and workpiece:

• Tool Installation & Calibration: We select tools (e.g., carbide, high-speed steel) matching the material and process, then mount them to the machine spindle (e.g., BT40 tool holders). Tool runout (radial/axial) is controlled within ≤0.02mm to avoid vibration during machining.

• Workpiece Clamping: The workpiece is fixed using specialized fixtures (e.g., vices, chucks, pressure plates). We use dial indicators to align the workpiece, ensuring positional accuracy within ≤0.01mm. For thin-walled or easily deformed parts, we use soft jaws or custom fixtures to minimize deformation.

• Machine Parameter Configuration: The G-code file is uploaded to the CNC control system (e.g., FANUC, SIEMENS). We perform tool setting (manual or automatic) to establish the workpiece coordinate system (e.g., G54-G59), ensuring precise positioning between the tool and workpiece.

4. Execution of Machining: Automated Precision Cutting

During the machining phase, the CNC machine operates autonomously according to the pre-programmed instructions, with real-time monitoring to ensure stability:

• Rough Machining: This stage focuses on efficiently removing excess material, leaving a small margin (e.g., 0.5mm) for finishing. We use high cutting depths (e.g., 2mm) and fast feed rates (e.g., 300mm/min) to maximize efficiency.

• Finish Machining: To achieve the final dimensional accuracy (e.g., ±0.01mm) and surface roughness (e.g., Ra0.8μm), we use small cutting depths (e.g., 0.1mm) and slow feed rates (e.g., 100mm/min). This stage ensures the part meets all design specifications.

• Online Monitoring: Our team monitors tool wear (via chip shape and cutting sound), cutting temperature (via infrared thermometers), and machine status in real time. This proactive monitoring prevents tool failure, workpiece deformation, and production interruptions.

5. Quality Control: Rigorous Verification

Quality is non-negotiable in our CNC Machining services. We implement multi-stage quality inspections to ensure every part meets the highest standards:

• Dimensional Inspection: We use precision measuring tools such as vernier calipers (accuracy ±0.02mm), micrometers (accuracy ±0.01mm), and Coordinate Measuring Machines (CMM, accuracy ±0.001mm) to verify critical dimensions and complex geometries.

• Surface Quality Inspection: Surface roughness testers and visual inspections are used to check for scratches, pits, or other defects. We ensure surface roughness meets client requirements (e.g., Ra0.1μm for mirror-finish parts).

• Error Analysis & Correction: If deviations are detected, our engineers analyze the root cause (e.g., tool wear, programming errors, clamping deformation) and implement corrective measures such as parameter adjustments or tool replacement.

6. Post-Processing: From Part to Finished Product

The final stage enhances the part’s appearance, performance, and usability, preparing it for delivery:

• Surface Treatment: We offer a range of surface treatments, including polishing (for smoothness), electroplating (for corrosion resistance), anodizing (for aluminum hardness and aesthetics), and spraying (for appearance parts).

• Cleaning & Drying: Parts are cleaned with detergents or ultrasonic cleaners to remove chips and oil, then dried (via compressed air or ovens) to prevent rust.

• Packaging & Delivery: Parts are packaged in bubble wrap, cartons, or custom foam to prevent damage during transportation. We provide detailed inspection reports (dimensional, surface quality) and deliver on time to clients worldwide.

Key Advantages of Our CNC Machining Services

Our CNC Machining services stand out in the market due to four core advantages, designed to deliver value to our clients:

1. Unmatched Precision & Consistency

With advanced CNC equipment and strict process control, we achieve tolerances as tight as ±0.001mm and surface roughness as low as Ra0.1μm. The automated nature of CNC Machining ensures every part in a batch is identical, eliminating the variability of manual machining.

2. High Efficiency & Cost-Effectiveness

Our optimized machining parameters (e.g., cutting speed, feed rate) and toolpath planning reduce production time significantly. For example, we have reduced tool change times by 40% for aerospace components and shortened cycle times by 35% for automotive parts. This efficiency translates to lower costs for small-batch prototypes and large-scale production alike.

3. Versatile Material Compatibility

We specialize in machining a wide range of materials, from common metals and plastics to high-performance alloys (titanium, Inconel) and composites. Our team has extensive experience in selecting the right tools, parameters, and processes for each material, ensuring optimal results.

4. Customized Solutions for Diverse Needs

Whether you need a single prototype, small-batch production, or mass manufacturing, we tailor our services to your specific requirements. Our engineering team collaborates with you from design to delivery, offering technical advice to optimize part design for manufacturability and reduce costs.

Widely Used Industry Applications

CNC Machining is a versatile technology that serves critical roles in multiple industries. Our clients span the following sectors, where precision and reliability are paramount:

Aerospace

We manufacture high-precision components such as turbine blades, engine parts, airframe structures, and landing gear components. These parts require lightweight, durable materials (titanium, aluminum) and strict tolerances to ensure flight safety.

Automotive

Our services support the production of engine blocks, transmission cases, brake system components, and custom prototypes. CNC Machining helps automotive manufacturers enhance part durability, improve performance, and accelerate production cycles.

Medical

We produce biocompatible components for surgical instruments, orthopedic implants (knee, hip, spinal), dental prosthetics, and MRI machine parts. These parts require extreme precision and compliance with medical industry standards.

Electronics

With the miniaturization of consumer electronics, we manufacture compact, high-precision parts such as smartphone frames, heat sinks, microchip housings, and connector components. Our high-speed CNC machines ensure efficient production of these small, intricate parts.

Energy

We support both renewable and conventional energy sectors with components for wind turbines, solar panel frames, oil and gas drilling equipment, and nuclear power plant parts. These parts require high strength and reliability to withstand harsh operating conditions.

Our Commitment

At China, we are dedicated to delivering high-quality CNC Machining services that exceed our clients’ expectations. Our commitment to precision, efficiency, and customer satisfaction drives every stage of our process. We invest in advanced equipment, continuous training for our team, and strict quality management systems to ensure consistent, reliable results.

Whether you are developing a new product, optimizing an existing design, or scaling up production, our CNC Machining services are your trusted partner in turning ideas into high-quality, precision components. Contact us today to discuss your project needs and discover how we can support your manufacturing goals.

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.