I. Basic Understanding

1. What is Magnesium Die Casting?

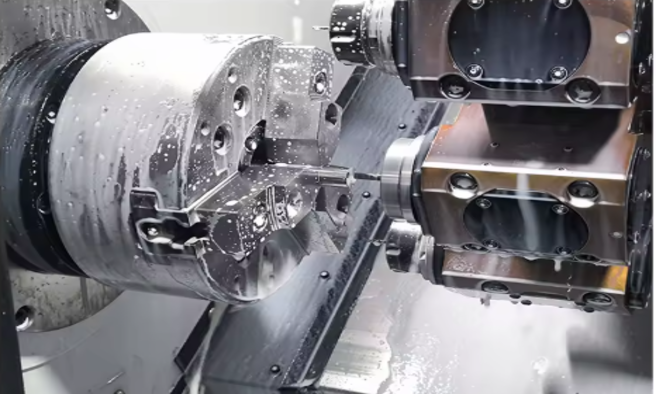

Magnesium die casting is a precision forming process that involves injecting molten magnesium alloy into a closed metal mold (die casting mold) under high pressure. After the alloy cools and solidifies, the mold is opened to remove the formed casting. Magnesium alloy has low density and high strength, and die casting enables the production of complex structures with high precision in large batches, making it widely used in lightweight demand scenarios.

2. What are the core differences between magnesium die casting and aluminum alloy die casting?

The core differences between the two stem from the material properties of magnesium and aluminum, specifically reflected in three aspects: ① Lightweight: The density of magnesium alloy (1.74g/cm³) is much lower than that of aluminum alloy (2.7g/cm³), so castings of the same structure are lighter, offering a significant weight reduction advantage; ② Mechanical properties: Magnesium alloy has higher specific strength and specific stiffness, as well as excellent impact resistance, but its corrosion resistance is slightly weaker than that of aluminum alloy (requiring additional protection); ③ Process adaptability: Magnesium alloy has a lower melting point (about 650℃) than aluminum alloy, resulting in lower energy consumption during die casting. It also has good fluidity, making it easier to form complex thin-walled parts. However, magnesium is prone to oxidation, requiring higher protection requirements for melting and pouring processes.

3. What are the commonly used magnesium alloy grades for die casting, and what are their applicable scenarios?

Mainstream industrial grades and their applicable scenarios: ① AZ91D: The most commonly used general-purpose grade, containing 9% aluminum and 1% zinc. It has moderate strength, excellent casting performance, and low cost, suitable for automotive parts (such as instrument panel brackets, transmission housings) and 3C casings; ② AM60B/AM50A: With aluminum content of 6%/5% and higher magnesium purity, they have better toughness and impact resistance than AZ91D, suitable for parts bearing impact loads (such as automotive seat frames, door inner panels); ③ AS41B: Containing 4% silicon, it has good high-temperature stability and wear resistance, suitable for high-temperature parts around engines; ④ WE43: Containing rare earth elements such as yttrium and neodymium, it has excellent corrosion resistance and high-temperature strength, used in aerospace and high-end military fields (with high cost).

II. Process Characteristics

4. What are the main process types of magnesium die casting?

Mainstream processes are divided into two categories: ① High-Pressure Cold Chamber Die Casting: The most commonly used method. Magnesium alloy ingots are melted in an independent furnace, then injected into the shot chamber of a cold chamber die casting machine. The molten metal is pressed into the mold by a high-pressure piston, suitable for mass production of high-precision complex parts such as automotive and 3C products; ② Semi-Solid Die Casting: Magnesium alloy is heated to a solid-liquid coexisting state (semi-solid slurry) before die casting. Castings produced by this method have fewer pores and shrinkage cavities, with higher mechanical properties, suitable for high-end precision parts but with higher equipment costs. In addition, there are special processes such as vacuum die casting (to reduce oxidation and pores) and squeeze casting, which adapt to different quality requirements.

5. What are the advantages of magnesium die casting?

Core advantages focus on lightweight and formability: ① Ultimate weight reduction: 35% lighter than aluminum alloy, helping end products (such as automobiles and UAVs) reduce energy consumption and improve endurance; ② Excellent formability: Molten magnesium alloy has good fluidity, enabling the casting of complex thin-walled parts with a wall thickness of 0.5-1mm. It also has high dimensional accuracy (tolerance up to ±0.02mm) and good surface finish, reducing subsequent processing; ③ Balanced mechanical properties: Higher specific strength and specific stiffness than most aluminum alloys, with good electromagnetic shielding performance, suitable for electronic and military scenarios; ④ Efficient process: Short die casting cycle (several seconds to tens of seconds per mold cycle) allows mass production. Moreover, magnesium alloy has a high recovery rate (over 95%), making it more environmentally friendly than some metal processing processes.

6. What are the limitations of magnesium die casting, and how to address them?

Main limitations and solutions: ① Poor corrosion resistance: Magnesium is prone to oxidation, forming a loose oxide film that cannot resist acid, alkali, and humid environments. Surface treatments (such as anodizing, micro-arc oxidation, electrophoretic coating, and chemical conversion coating) are required to improve protection; ② High cost: The price of magnesium alloy raw materials is higher than that of aluminum alloy, and inert gases (such as SF₆, CO₂+SF₆ mixed gas) are needed for protection during melting, increasing process costs. Costs can be amortized through mass production and optimizing mold life (selecting hot work die steel H13 and optimizing heat treatment); ③ Limited high-temperature performance: Conventional magnesium alloys (such as AZ91D) experience significant strength reduction above 120℃. High-temperature resistant grades (such as AS41B, WE43) or structural design optimization should be adopted; ④ Flammability risk: Molten magnesium is flammable when exposed to air, requiring strict sealing protection during melting and die casting, as well as special flame-retardant furnaces and safe operating procedures.

III. Applications and Quality

7. In which industries are magnesium die castings mainly used?

Core applications cover three major fields: ① Automotive industry (accounting for over 60%): Lightweight body parts (door inner panels, hood brackets), powertrain components (transmission housings, oil pans), and interior parts (instrument panel skeletons), helping improve the endurance of new energy vehicles; ② 3C electronics industry: Laptop casings, mobile phone middle frames, tablet brackets, and camera bodies, balancing light weight and impact resistance; ③ Aerospace and military: UAV frames, satellite components, and firearm accessories, leveraging their lightweight and high specific strength advantages. In addition, they are also used in medical devices (wheelchair parts) and power tool casings.

8. What are the common defects of magnesium die castings and their causes?

Typical defects and their causes: ① Porosity: Formed by gas absorption (such as H₂) by molten magnesium alloy or poor mold venting during die casting, causing gas retention after cooling; ② Shrinkage cavity/porosity: Uneven cooling rate in thick-walled parts of the casting, insufficient molten metal feeding, leading to internal porosity; ③ Oxide inclusions: Magnesium alloy reacts with air during melting or pouring, generating MgO impurities that mix into the casting; ④ Cracks: Caused by excessive/insufficient mold temperature, unreasonable casting structure (such as sharp corners, sudden wall thickness changes), or excessive cooling rate leading to stress concentration; ⑤ Surface scratches: Caused by insufficient mold surface finish, improper use of release agent, or adhesion between the casting and the mold.

9. How to inspect the quality of magnesium die castings?

Inspection is divided into three categories: appearance, internal, and performance testing: ① Appearance inspection: Visual inspection and magnifying glass inspection for surface scratches, depressions, cracks, etc., or surface finish testing with a roughness meter; ② Internal inspection: X-ray Testing (RT) and Ultrasonic Testing (UT) are used to detect internal defects such as pores, shrinkage cavities, and inclusions, suitable for high-end precision parts; ③ Mechanical performance testing: Sampling testing for tensile strength, yield strength, and elongation (via tensile test), and hardness testing (Brinell, Rockwell hardness tester); ④ Composition inspection: Spectrometer analysis of magnesium alloy composition to ensure compliance with corresponding grade standards; ⑤ Sealing inspection: Air tightness and water tightness testing for waterproof and leak-proof parts (such as housings).

IV. Production and Environmental Protection

10. What are the requirements for molds in magnesium die casting?

Molds must be adapted to magnesium alloy characteristics: ① Material: High-temperature and wear-resistant hot work die steel (such as H13, S136) should be selected, with nitriding, quenching, and other heat treatments to improve mold hardness (HRC 45-52) and service life; ② Structure: Reasonable gating system (ensuring uniform filling of molten metal), venting system (quickly exhausting gas in the mold to reduce porosity), and cooling channels (controlling mold temperature to avoid local overheating or uneven cooling) should be designed; ③ Surface treatment: Mold cavities need to be polished to high finish or sprayed with special release agents to prevent casting adhesion and scratches.

11. How environmentally friendly is magnesium die casting, and can scrap be recycled?

It has significant environmental advantages and efficient scrap recyclability: ① Production process: Magnesium die casting consumes less energy than aluminum alloy die casting (due to lower melting point) and produces no toxic or harmful substances. Only a small amount of release agent waste liquid needs to be treated (which can reach discharge standards through sewage treatment); ② Scrap recycling: Magnesium alloy has an extremely high recovery rate. Scrap generated during die casting, such as runners, waste castings, and chips, can be reused in die casting after sorting, impurity removal, and remelting, with a recycling rate of over 95%, complying with circular economy requirements; ③ Substitution advantage: Replacing steel and iron parts with magnesium die castings can reduce energy consumption of end products and indirectly reduce carbon emissions.

12. What are the key points of production safety specifications for magnesium die casting?

Core safety points focus on flame retardancy and protection: ① Melting protection: Closed furnaces should be used, and inert gases (SF₆+CO₂ mixed gas) should be introduced to isolate air and prevent oxidation and combustion of molten magnesium; contact between molten magnesium and water or humid materials is strictly prohibited (which may cause explosion); ② On-site protection: Production areas should be equipped with dry powder fire extinguishers (water is prohibited for fire fighting), fire sand, and emergency protective masks. Operators must wear high-temperature resistant protective clothing, safety shoes, and goggles; ③ Scrap disposal: Magnesium alloy scrap should be stored separately to avoid mixing with other metal scrap. It must be dried and degreased before disposal to prevent spontaneous combustion; ④ Equipment maintenance: Regularly inspect the sealing performance of die casting machines and furnaces, as well as gas pipelines, to eliminate leakage risks.

V. Selection and Cost

13. Which products are suitable for magnesium die casting instead of aluminum alloy die casting?

Scenarios where magnesium die casting is preferred: ① Products with extremely high lightweight requirements (weight reduction of over 30%) while ensuring strength (such as UAV frames, new energy vehicle battery trays); ② Complex thin-walled parts (wall thickness ≤1.5mm) pursuing high precision and low subsequent processing volume (such as laptop casings); ③ Parts requiring electromagnetic shielding, shock absorption, and noise reduction (such as electronic device housings, automotive interior brackets). For products with high corrosion resistance requirements, cost sensitivity, and no urgent lightweight needs, aluminum alloy die casting is recommended.

14. What constitutes the cost of magnesium die casting, and how to control costs?

Cost composition (sorted by proportion): ① Raw material cost (40%-50%): The price of magnesium alloy ingots is higher than that of aluminum alloy; ② Process cost (20%-30%): Including consumption of inert gases, energy, release agents, etc.; ③ Mold cost (10%-15%): High initial investment in high-precision molds; ④ Labor and inspection cost (10%-15%). Cost control methods: ① Mass production to amortize mold and equipment depreciation costs; ② Optimize casting structure to reduce uneven wall thickness and scrap rate; ③ Select cost-effective magnesium alloy grades (such as AZ91D instead of WE43 for non-high-temperature scenarios); ④ Optimize melting processes to reduce molten magnesium loss and improve scrap recycling rate.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.