1. Basic Cognition

1. What is Zinc Die Casting?

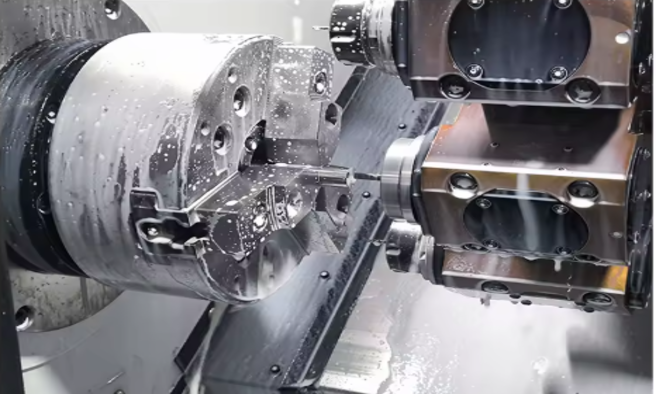

Zinc die casting is a metal forming process where molten zinc alloy is injected into a precision mold cavity under high pressure, then cooled and solidified to produce metal structural components. Its core characteristics include high pressure (usually 10-175 MPa) and high-speed mold filling, enabling the rapid mass production of parts with high dimensional accuracy, excellent surface quality, and complex structures.

2. What are the common zinc alloy grades for die casting, and what are their respective characteristics?

The mainstream grade in the industry is the Zamak series (zinc-aluminum alloy). The core grades and their characteristics are as follows:

• Zamak 3: The most widely used, featuring excellent casting performance, mechanical strength, and corrosion resistance. Suitable for manufacturing household appliance housings, auto parts, hardware accessories, etc.

• Zamak 5: Compared with Zamak 3, it has higher hardness, tensile strength, and better dimensional stability. Commonly used for parts requiring higher strength, such as gears, connectors, and valve components.

• Zamak 7: Low impurity content and excellent ductility, suitable for parts requiring subsequent stamping or bending. It also has stronger corrosion resistance, making it applicable to outdoor or humid environment components.

• ZA Series (e.g., ZA-8, ZA-12): Higher aluminum content, mechanical strength far exceeding ordinary Zamak alloys. Suitable for parts under heavy load and high-temperature environments, but with slightly higher casting difficulty.

3. What are the core differences between zinc die casting and other die casting processes (e.g., aluminum alloy die casting, magnesium alloy die casting)?

The core differences stem from the material properties of zinc alloys, with specific comparisons as follows:

• Lower Melting Point: The melting point of zinc alloy is about 380-420℃, much lower than that of aluminum alloy (660℃) and magnesium alloy (650℃). This results in lower energy consumption and less mold wear during casting, with mold life 3-5 times that of aluminum alloy die casting.

• Better Filling Performance: Molten zinc alloy has excellent fluidity, capable of filling more complex and thinner mold cavities. It can produce precision parts with a wall thickness of 0.3-0.5mm, while aluminum and magnesium alloys have higher difficulty in forming thin-walled parts.

• Cost Advantage: Zinc alloy has a moderate raw material cost and high casting efficiency (short forming cycle). For mass production, the unit part cost is lower than magnesium alloy die casting and slightly lower than aluminum alloy die casting (depending on specific structures).

• Weight: Zinc alloy has a higher density (6.6-6.7g/cm³) than aluminum alloy (2.7g/cm³) and magnesium alloy (1.8g/cm³), making it unsuitable for scenarios with extremely high lightweight requirements (e.g., aerospace, new energy vehicle weight-reduction components).

2. Process & Production

1. What is the range of minimum wall thickness and maximum size for zinc die castings?

General process parameters: The minimum wall thickness can reach 0.3mm (suitable for small precision parts such as electronic connector pins), but it must be combined with part size and structure. Excessively thin walls may cause defects like insufficient filling and porosity. The maximum forming size is limited by die casting machine tonnage and mold. Common part weight ranges from 0.1g to 5kg, while large zinc die castings (e.g., household appliance housings) can reach 10-15kg, requiring matching large-scale die casting equipment.

2. What is the achievable dimensional tolerance accuracy of zinc die castings?

Dimensional accuracy mainly depends on mold precision, part structure, and alloy type, generally reaching CT4-CT6 grade (precision grade) according to ISO 8062 standard. For simple-structure, small-to-medium-sized parts, linear tolerance can be controlled within ±0.01-±0.05mm; for complex-structure or large parts, tolerance is usually ±0.05-±0.1mm, and accuracy can be further improved through subsequent finishing.

3. What are the common surface treatment methods for zinc die castings?

To improve corrosion resistance, aesthetics, or functionality, common surface treatment processes include:

• Electroplating: Zinc plating, chrome plating, nickel plating, etc., to enhance corrosion resistance and decoration. Suitable for auto parts and hardware.

• Coating: Powder coating, electrophoretic coating, forming a uniform protective film. Suitable for household appliance housings and outdoor parts.

• Anodizing: Only applicable to ZA series zinc alloys with high aluminum content, forming a wear-resistant and corrosion-resistant oxide film.

• Passivation: Chemical passivation (e.g., chromate passivation, chrome-free passivation), a low-cost method to improve corrosion resistance. Commonly used for internal structural parts.

• Polishing & Brushing: Improve surface finish to meet decorative requirements.

4. What are the common defects in zinc die casting production, and how to avoid them?

Core defects and preventive measures:

• Porosity: Caused by gas entrainment in molten zinc alloy or poor mold ventilation. Prevention: Optimize melting process (degassing treatment), design reasonable vent channels, and control filling speed and temperature.

• Shrinkage Cavity/Shrinkage Porosity: Caused by uneven volume shrinkage during cooling. Prevention: Optimize mold gating system, set risers (feeding channels), control cooling speed, and avoid local overheating.

• Cracks: Caused by low mold temperature or unreasonable part structure (e.g., sharp corners, sudden wall thickness changes). Prevention: Preheat mold to a reasonable temperature (150-250℃), optimize part structure (fillet transition, uniform wall thickness), and control demolding speed.

• Surface Scratching: Caused by rough mold surface or insufficient lubrication. Prevention: Polish mold cavity, use special die casting lubricant, and control the fit clearance between mold and part.

3. Application & Material Selection

1. In which industries and scenarios are zinc die castings mainly used?

With advantages of precision, high efficiency, and low cost, they are widely used in:

• Automotive Industry: Door lock assemblies, gears, instrument panel brackets, shock absorbers, connectors.

• Household Appliance Industry: Washing machine inner tub brackets, refrigerator hinges, air conditioner compressor parts, small household appliance housings.

• Electronics Industry: Mobile phone middle frames, connectors, sensor housings, power adapter housings.

• Hardware Tools: Wrenches, screwdriver handles, door lock cores, bathroom accessories.

• Medical Devices: Small medical device housings, precision transmission parts (meeting biocompatibility requirements).

2. When is zinc die casting preferred over other processes (e.g., injection molding, sheet metal, aluminum alloy die casting)?

Scenarios where zinc die casting is preferred:

• Mass Production (suggested batch size ≥1000 pieces): High casting efficiency can amortize mold costs, suitable for large-scale mass production.

• Parts requiring high precision and complex structure: Zinc alloy’s good fluidity enables forming complex cavities without extensive subsequent processing.

• Parts with certain strength and wear resistance requirements: Zinc alloy has better mechanical properties than plastic and lower cost than magnesium alloy.

• Pursuing a balance between low cost and surface quality: Compared with aluminum alloy die casting, zinc die casting has longer mold life, lower energy consumption, and easier surface treatment.

3. Can zinc die castings be used in outdoor or humid environments?

Yes, but corrosion protection measures are necessary. Zinc alloy itself has moderate corrosion resistance and is prone to oxidation and blackening in outdoor humid environments. Therefore, a protective film must be formed through surface treatments such as electroplating, coating, or passivation. For highly corrosive environments (e.g., coastal areas, chemical scenarios), it is recommended to use Zamak 7 or ZA series alloys, combined with a composite treatment process of chrome-free passivation + coating.

4. Cost & Environmental Protection

1. What are the main components of zinc die casting costs, and how to control costs?

Cost composition (in descending order of proportion): Raw material cost (zinc alloy ingots), mold cost, labor & energy cost, surface treatment cost.

Cost control methods: Optimize part structure (reduce complex cavities to lower mold difficulty), increase batch size (amortize mold costs), select cost-effective Zamak 3 alloy (for non-high-strength scenarios), simplify surface treatment processes (e.g., replace electroplating with passivation), and optimize production processes (improve qualification rate and reduce waste).

2. Can zinc die casting scrap be recycled? How environmentally friendly is it?

Zinc die casting scrap (gates, risers, unqualified parts) can be 100% recycled and reused, with recycling energy consumption only about 1/4 of primary zinc production, showing excellent environmental performance. Currently, the industry mainly adopts a closed-loop recycling model. After remelting and impurity removal, scrap can be directly used for die casting production, reducing both raw material costs and resource waste. In addition, zinc alloy is non-toxic, and surface treatment processes (e.g., chrome-free passivation) can meet environmental standards, complying with international certifications such as RoHS and REACH.

5. Quality & Testing

1. What are the quality testing items for zinc die castings?

Routine testing items include: Dimensional tolerance testing (calipers, micrometers, coordinate measuring machines), appearance quality testing (visual inspection, magnifying glass, surface roughness tester), mechanical property testing (tensile strength, hardness, ductility tests), internal defect testing (X-ray flaw detection, ultrasonic flaw detection to check porosity and shrinkage), and corrosion resistance testing (salt spray test, damp heat test).

2. What industry standards must zinc die castings comply with?

Mainstream international and domestic standards:

• International Standards: ASTM B863 (Standard for Zinc Alloy Die Castings), ISO 3011 (Mechanical Property Requirements for Zinc Alloy Die Castings).

• Domestic Standards: GB/T 13818 (Zinc Alloy Die Castings), GB/T 1173 (Cast Zinc Alloys).

• Industry-Specific Standards: The automotive industry requires compliance with IATF 16949 certification; the electronics industry must meet RoHS and REACH environmental standards; medical devices need to comply with ISO 13485 certification.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.