1. Basic Cognition

1.1 What is CNC Finishing?

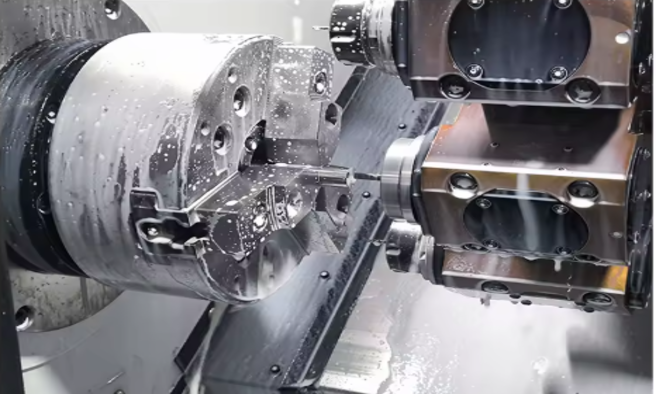

CNC Finishing refers to the precision machining process that polishes, trims, and optimizes the surface and dimensions of workpieces after rough machining (e.g., CNC milling, turning). Its core purpose is to eliminate processing traces (such as tool marks, burrs) left by rough machining, improve surface quality (reduce roughness), ensure dimensional accuracy and shape tolerance, and enhance the workpiece’s mechanical properties (e.g., wear resistance) and appearance. It is a key process for high-precision, high-quality mechanical parts, widely used in aerospace, precision instruments, automotive core components and other fields.

1.2 What is the difference between CNC Finishing and CNC Roughing?

The core differences lie in processing goals, parameters and effects: ① Processing Goal: Roughing focuses on quickly removing most of the excess material to approach the workpiece’s basic shape and size, prioritizing efficiency; finishing focuses on precision and surface quality, ensuring the workpiece meets design standards. ② Processing Parameters: Roughing uses large cutting depth, high feed rate and low speed, with large cutting force; finishing uses small cutting depth (usually 0.05-0.5mm), low feed rate and high speed, with small cutting force. ③ Processing Effects: Roughing leaves obvious tool marks and has low dimensional accuracy; finishing eliminates tool marks, reduces surface roughness (Ra can reach 0.02-1.6μm), and ensures high-precision dimensional control.

1.3 What are the core evaluation indicators of CNC Finishing quality?

Key evaluation indicators include: ① Surface Roughness (Ra/Rz): The smaller the Ra value, the smoother the surface (e.g., Ra ≤ 0.8μm for decorative parts, Ra ≤ 0.2μm for precision mating parts); ② Dimensional Accuracy: Including size tolerance (e.g., ±0.005mm), shape tolerance (flatness, cylindricity) and position tolerance (coaxiality, parallelism); ③ Surface Integrity: No scratches, burrs, cracks or residual stress; ④ Mechanical Properties: For metal workpieces, finishing can improve surface hardness and wear resistance (e.g., through precision grinding).

2. Common Processes and Selection

2.1 What are the common CNC Finishing processes?

Common processes are classified by processing method: ① Precision Cutting: Such as finish milling, finish turning, boring and reaming, using high-precision tools and parameters to achieve fine surface and dimensional accuracy; ② Abrasive Machining: Such as precision grinding, honing, lapping, using abrasive tools (grinding wheels, honing strips) to remove micro-material, suitable for ultra-high precision parts (Ra ≤ 0.1μm); ③ Polishing & Buffing: Manual or mechanical polishing with abrasive paste, wool wheels, etc., to improve surface gloss (for decorative parts); ④ Electrochemical Finishing: Such as electrolytic polishing, using electrochemical reaction to dissolve surface burrs and tool marks, suitable for stainless steel, aluminum alloy parts; ⑤ Deburring: Including mechanical deburring (brush deburring) and thermal deburring, focusing on removing edge burrs.

2.2 How to select the appropriate CNC Finishing process?

Selection is based on multiple factors: ① Workpiece Material: Hard materials (titanium alloy, hardened steel) are suitable for grinding, while soft materials (aluminum alloy, copper) are suitable for polishing or electrolytic finishing; ② Surface Requirements: For ultra-high precision (Ra ≤ 0.2μm), select lapping or honing; for decorative glossy surfaces, select buffing; ③ Dimensional Requirements: Finish turning/boring are suitable for rotating parts; finish milling for planar or curved parts; ④ Production Efficiency: Mechanical finishing (finish cutting) is faster than manual polishing; batch parts can use automated deburring equipment; ⑤ Cost Budget: Electrochemical finishing and precision lapping have higher costs than conventional finish cutting.

2.3 What is the application scenario of honing and lapping in CNC Finishing?

① Honing: Mainly used for finishing inner holes (e.g., engine cylinders, hydraulic cylinders), with high roundness and cylindricity accuracy (tolerance ≤ 0.001mm) and low surface roughness (Ra ≤ 0.1μm). It can correct minor shape deviations of holes caused by rough machining, suitable for parts requiring tight fit with shafts; ② Lapping: Uses lapping paste and lapping tools (lap) for micro-cutting, applicable to flat surfaces, spherical surfaces and small holes (e.g., precision bearings, optical components). It achieves ultra-high precision (Ra ≤ 0.02μm) but has low efficiency, suitable for small-batch, ultra-high precision parts.

3. Material Adaptation and Tool Selection

3.1 How to match CNC Finishing processes with different materials?

Material-specific matching principles: ① Steel (Carbon Steel/Alloy Steel): Hardened steel (HRC ≥ 50) uses precision grinding; unhardened steel uses finish turning/milling with carbide tools, or electrolytic polishing for glossy surfaces; ② Aluminum Alloy/Copper Alloy: Soft materials prone to sticking to tools, use diamond tools for finish cutting, or mechanical polishing + anodizing for decorative effects; avoid abrasive machining that may cause surface scratches; ③ Titanium Alloy/Superalloy: High hardness and poor thermal conductivity, use ceramic or PCBN tools for finish cutting, or creep feed grinding to reduce heat generation; ④ Engineering Plastics (ABS/PC): Use high-speed finish milling with solid carbide tools (sharp cutting edge), avoid high temperature to prevent material deformation; surface polishing with fine sandpaper.

3.2 What are the requirements for tools in CNC Finishing?

Core tool requirements: ① High Precision: Tool runout ≤ 0.002mm, cutting edge finish Ra ≤ 0.02μm, ensuring no additional tool marks on the workpiece; ② High Hardness & Wear Resistance: For metal finishing, use carbide, PCBN or diamond tools; avoid tool wear leading to surface defects; ③ Sharp Cutting Edge: Reduce cutting force and friction, avoid tearing the workpiece surface (especially soft materials like aluminum alloy); ④ Tool Structure: Use tools with fewer flutes (2-3 flutes for finishing) to reduce cutting resistance and chip accumulation; ⑤ Coating Optimization: TiAlN, DLC coatings improve tool wear resistance and reduce sticking (suitable for stainless steel, aluminum alloy).

3.3 Why do soft materials (aluminum alloy) easily have surface defects in finishing, and how to avoid them?

Causes: Soft materials have low hardness, easy to stick to the tool cutting edge (forming built-up edge), leading to scratches, burrs or uneven surfaces. Prevention methods: ① Use diamond or DLC-coated tools with sharp cutting edges to reduce sticking; ② Increase cutting speed (aluminum alloy: 3000-8000r/min) and reduce feed rate (0.05-0.15mm/r) to avoid built-up edge; ③ Use cutting fluid with good lubricity (e.g., ester-based cutting fluid) to reduce friction; ④ Regularly clean the tool cutting edge to remove residual material; ⑤ Avoid excessive cutting depth, use multi-pass fine cutting (each pass 0.05-0.1mm).

4. Precision Control and Parameter Setting

4.1 What factors affect the surface precision of CNC Finishing?

Key influencing factors: ① Machine Tool Precision: Spindle runout, guideway clearance, repeat positioning accuracy (require ≤ 0.003mm for finishing machines); ② Tool Quality: Tool wear, runout and cutting edge sharpness; ③ Processing Parameters: Improper speed, feed rate or cutting depth leads to tool vibration or surface tearing; ④ Workpiece Clamping: Excessive clamping force causes deformation, affecting dimensional accuracy; insufficient clamping leads to vibration; ⑤ Environmental Factors: Temperature fluctuation (affects thermal deformation of machine and workpiece), vibration (needs anti-vibration pads) and dust (pollutes surface); ⑥ Cutting Fluid: Poor lubrication/cooling causes surface defects.

4.2 How to set core finishing parameters (speed, feed rate, cutting depth)?

Parameter setting guidelines (take metal materials as examples): ① Cutting Speed (S): Determined by tool and material—aluminum alloy (carbide tool): 3000-8000r/min; stainless steel (carbide tool): 800-1500r/min; hardened steel (PCBN tool): 1500-3000r/min; ② Feed Rate (F): Lower than roughing, 0.05-0.2mm/r for finish turning/milling; 0.02-0.08mm/r for ultra-high precision parts; ③ Cutting Depth (Ap): 0.05-0.5mm for finish cutting; 0.02-0.1mm for ultra-fine finishing (to remove tool marks from roughing); ④ Additional Settings: Use constant surface speed (CSS) for rotating parts; adopt multi-pass fine cutting to improve surface uniformity; avoid sudden speed/feed changes to prevent vibration.

4.3 How to avoid workpiece deformation during CNC Finishing?

Prevention measures: ① Optimize Clamping: Use soft jaws, fixture pads or vacuum clamping for thin-walled parts to reduce clamping force; adopt multi-point positioning to distribute force evenly; ② Reduce Cutting Force: Use small cutting depth, low feed rate and sharp tools to minimize cutting force and residual stress; ③ Heat Control: Use sufficient cutting fluid to reduce thermal deformation; avoid processing at high temperature for heat-sensitive materials; ④ Process Sequence: For complex parts, finish machining after rough machining (with stress relief annealing if necessary); ⑤ Post-Processing: Perform stress relief treatment (e.g., low-temperature annealing) for parts prone to deformation to stabilize dimensions.

5. Fault Troubleshooting

5.1 Why do finishing workpieces have obvious tool marks, and how to solve it?

Causes: ① Tool wear or dull cutting edge; ② Excessive feed rate or cutting depth; ③ Tool vibration (insufficient rigidity or high speed); ④ Improper tool path (e.g., sharp corner without transition); ⑤ Cutting fluid insufficiently covers the cutting area. Solutions: ① Replace or regrind the tool, ensure sharp cutting edge; ② Reduce feed rate (to ≤ 0.1mm/r) and cutting depth (to ≤ 0.1mm); ③ Shorten tool extension length, increase tool rigidity; reduce speed if vibration occurs; ④ Optimize tool path, add arc transition at corners; ⑤ Adjust cutting fluid flow rate and direction, ensure full lubrication/cooling.

5.2 How to solve surface scratches or unevenness in finishing?

Causes: ① Built-up edge on tool (scratching workpiece); ② Chips adhering to the workpiece surface; ③ Cutting fluid contains impurities; ④ Tool runout exceeds standard; ⑤ Workpiece surface is contaminated before finishing. Solutions: ① Use coated tools or increase speed to eliminate built-up edge; clean tool edge regularly; ② Use chip breakers or adjust parameters to avoid chip adhesion; remove chips in time; ③ Replace cutting fluid, clean the filter; ④ Calibrate tool runout (use dial indicator to detect, require ≤ 0.002mm); ⑤ Clean the workpiece surface with alcohol before finishing, avoid dust or oil contamination.

5.3 Why do finishing workpieces have dimensional deviation, and how to troubleshoot?

Troubleshooting directions: ① Machine Tool: Check spindle runout, guideway wear and positioning accuracy; calibrate if deviation exists; ② Tool: Check tool wear (wear leads to size change) and tool length compensation (incorrect value); ③ Clamping: Loosen the fixture and measure the workpiece—if size returns to normal, it is caused by clamping deformation; adjust clamping force; ④ Temperature: Check if the workpiece/machine is overheated (thermal deformation); strengthen cooling or pause processing to cool down; ⑤ Measurement: Verify if the measuring tool is calibrated, measure after the workpiece cools to room temperature (avoid thermal expansion error); ⑥ Parameters: Check if speed/feed rate is too high (causing vibration and size deviation).

6. Cost and Efficiency Optimization

6.1 What factors affect the cost of CNC Finishing?

Main cost factors: ① Tool Cost: High-precision tools (diamond, PCBN) are expensive, and wear rate affects replacement frequency; ② Processing Time: Ultra-high precision finishing takes long time, increasing labor and energy costs; ③ Post-Processing: Manual polishing, deburring or surface treatment (e.g., electroplating) adds cost; ④ Equipment Cost: High-precision CNC machines and finishing equipment (honing machine, lapping machine) have high purchase and maintenance costs; ⑤ Scrap Rate: High precision requirements lead to higher scrap rate, increasing cost.

6.2 How to balance finishing quality and production efficiency?

Balancing methods: ① Parameter Optimization: Select the optimal speed/feed rate (not the lowest feed rate) to ensure quality while shortening time; use multi-pass fine cutting with appropriate cutting depth; ② Tool Selection: Use high-wear-resistance coated tools to reduce tool replacement frequency; ③ Process Integration: Integrate finish cutting and deburring into one process (e.g., use deburring tools in CNC machine) to reduce secondary operations; ④ Automation Upgrade: Use automated polishing equipment, tool changers and online measurement to reduce manual intervention; ⑤ Batch Processing: For batch parts, optimize tool path to reduce idle travel; use dedicated fixtures for quick clamping.

6.3 How to reduce tool consumption cost in CNC Finishing?

Cost-saving strategies: ① Tool Maintenance: Regularly regrind sharp tools (e.g., carbide end mills) to extend service life; clean tools after use to avoid residual material corrosion; ② Parameter Matching: Avoid excessive cutting force (which accelerates tool wear) by optimizing speed, feed rate and cutting depth; ③ Coating Selection: Use appropriate tool coatings (TiAlN for steel, DLC for aluminum alloy) to improve wear resistance; ④ Tool Management: Classify and store tools to avoid damage; use tool life management functions to replace tools before excessive wear; ⑤ Cost-Effective Tools: For general precision parts, use high-quality carbide tools instead of expensive diamond/PCBN tools; for ultra-high precision parts, use dedicated tools to avoid scrap.

7. Safety and Operation Specifications

7.1 What are the core safety precautions for CNC Finishing?

Key safety notes: ① High-Speed Operation: Finishing uses high spindle speed—ensure the tool is firmly installed, avoid tool flying out; do not touch the rotating tool or workpiece; ② Cutting Fluid Safety: Use cutting fluid in a well-ventilated area; wear gloves and goggles to avoid splashing; avoid skin contact with corrosive cutting fluid; ③ Clamping Safety: Ensure the workpiece is firmly clamped to prevent flying due to vibration; do not adjust clamping during processing; ④ Equipment Inspection: Check machine tool spindle, guideway and tool runout before processing; confirm no abnormalities before starting; ⑤ Emergency Handling: Press the emergency stop button immediately in case of tool breakage, vibration or surface defects; cut off power before maintenance.

7.2 How to maintain CNC finishing equipment to ensure processing precision?

Equipment maintenance measures: ① Daily Cleaning: Clean the spindle, guideway, tool holder and workpiece table after processing to remove cutting fluid residue and chips; ② Lubrication: Regularly add lubricating oil to guideways, screws and spindle bearings to ensure smooth movement and reduce wear; ③ Precision Calibration: Regularly calibrate spindle runout, guideway parallelism and machine positioning accuracy (use laser interferometer for high-precision calibration); ④ Tool Holder Maintenance: Clean the tool holder and spindle taper hole to avoid runout caused by dirt; check tool holder wear regularly; ⑤ Cutting Fluid System: Replace cutting fluid regularly, clean the filter and pipeline to ensure lubrication/cooling effect; ⑥ Electrical System: Keep the electrical cabinet ventilated and dry; check circuit connections to avoid equipment failure.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.