1. Basic Cognition

1.1 What is CNC Milling?

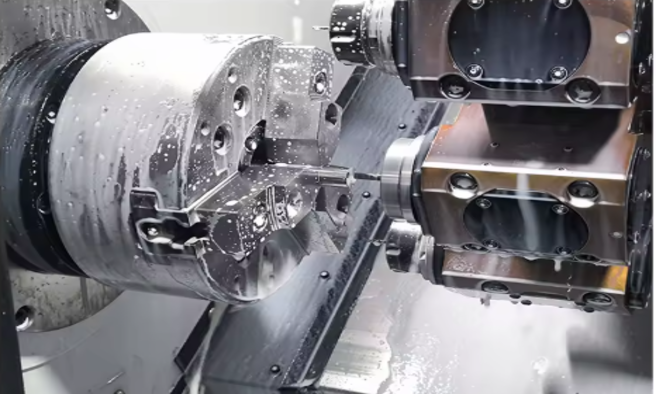

CNC Milling, or Computer Numerical Control Milling, is a precision manufacturing process that uses a computer numerical control (CNC) system to drive a milling machine, cutting workpieces with rotating tools. It enables automated, high-precision machining of complex structures such as planes, curved surfaces, grooves, and hole systems, and is widely applied in mechanical manufacturing, aerospace, auto parts, and other fields. Compared with traditional manual milling, it significantly improves efficiency, precision, and consistency.

1.2 What are the main types of CNC milling machines?

Classified by structure and function, they include: Vertical Milling Machines (with vertically arranged spindles, suitable for machining small and medium workpieces, planes, and cavities, most widely used); Horizontal Milling Machines (with horizontally arranged spindles, suitable for deep cavity and polyhedron machining, often equipped with dividing heads or turntables); Gantry Milling Machines (beam-type structure, suitable for machining large, heavy workpieces such as machine beds and large frames); 5-Axis Milling Machines (capable of multi-dimensional linkage machining, solving one-time forming of complex curved surfaces and special-shaped parts).

1.3 What is the core difference between CNC Milling and CNC Turning?

The core difference lies in the machining method and applicable workpieces: In CNC Milling, the tool rotates while the workpiece is fixed or moves, suitable for machining workpieces with planes, curved surfaces, irregular contours, and porous structures (such as boxes and brackets); In CNC Turning, the workpiece rotates while the tool feeds fixedly, suitable for machining rotating parts such as shafts and discs (such as bolts and bearing sleeves). Simply put, milling focuses on "milling forming", while turning focuses on "rotational cutting forming".

2. Material and Process Adaptation

2.1 What materials can be processed by CNC milling?

Almost all metal materials can be processed, including steel (carbon steel, alloy steel, stainless steel), aluminum alloy, copper alloy, titanium alloy, magnesium alloy, etc.; meanwhile, some non-metallic materials can be processed, such as engineering plastics (ABS, PC, POM), wood, acrylic, composite materials, etc. Different materials require matching tools, cutting parameters, and cooling methods. For example, titanium alloy has high hardness and poor thermal conductivity, requiring carbide tools + low-speed high-feed + sufficient cooling.

2.2 How to select tools for CNC milling?

Tool selection should consider three key factors: ① Material: Carbide tools are used for machining hard steel; high-speed steel or carbide tools (anti-sticking required) for aluminum alloy; ② Machining Type: Face mills for plane milling, end mills for groove machining, drills and reamers for hole machining; ③ Precision Requirement: Coated tools (such as TiN, TiAlN coatings, improving hardness and wear resistance) for high-precision machining, uncoated tools for general machining. In addition, the number of flutes and helix angle of the tool should be adjusted according to machining needs.

2.3 What is the role of cooling and lubrication in CNC milling? What are the common cooling methods?

Role: Reduce cutting temperature (avoid tool overheating wear and workpiece deformation), reduce friction between tool and workpiece (prevent sticking), flush chips (avoid chip scratching on workpiece surface), and improve machining precision and surface quality. Common cooling methods: ① Wet Cooling (liquid cutting fluid, most widely used, suitable for most metal machining); ② Dry Cooling (no cutting fluid, suitable for workpieces with high environmental requirements and fear of pollution, such as some aluminum alloys and plastics); ③ Minimum Quantity Lubrication (MQL) (micro-cutting fluid spray, balancing cooling effect and environmental protection).

3. Precision and Parameter Setting

3.1 What factors affect the machining precision of CNC milling?

Main factors include: ① Machine Precision: Spindle runout, guideway clearance, positioning accuracy (repeat positioning accuracy within ±0.005mm is preferred); ② Tool Precision: Tool runout, wear level, cutting edge quality; ③ Fixture Precision: Fixture positioning error, clamping force (excessive clamping force easily causes workpiece deformation); ④ Programming Precision: Tool path planning, feed rate and spindle speed setting, compensation parameters (tool length compensation, radius compensation); ⑤ Environmental Factors: Workshop temperature fluctuation (affecting thermal deformation of machine and workpiece), vibration (keeping away from vibration sources).

3.2 How to set feed rate (F), spindle speed (S), and depth of cut (Ap)?

The three need to be matched collaboratively, based on tool material, workpiece material, and machining type: ① Spindle Speed (S): The higher the hardness of the material, the lower the speed (e.g., 800-1500r/min for stainless steel, 3000-8000r/min for aluminum alloy). Reference formula: S=1000×vc/(π×D) (vc = cutting speed, D = tool diameter); ② Feed Rate (F): Related to speed and number of tool flutes. Formula: F=S×z×fz (z = number of tool flutes, fz = feed per tooth, generally 0.1-0.3mm/tooth for carbide tools); ③ Depth of Cut (Ap): Larger depth can be used for rough machining (e.g., 2-5mm) to improve efficiency; smaller depth for finish machining (e.g., 0.1-0.5mm) to ensure precision, surface quality, and avoid workpiece deformation.

3.3 What is the role of tool compensation (length compensation, radius compensation)? How to use it?

Role: Compensate for the impact of tool wear, installation errors, and tool length/radius changes on machining precision, avoiding reprogramming. ① Length Compensation: After tool replacement or wear, there is no need to adjust the programming origin; only input the tool length compensation value into the system to offset the difference between the actual tool length and the theoretical length; ② Radius Compensation: When machining contours, the tool center path needs to deviate from the workpiece contour by a tool radius. With the radius compensation function, programming can be directly based on the workpiece contour, and the system automatically calculates the tool center path, facilitating tool radius adjustment or wear correction. Pay attention to the compensation direction (left compensation, right compensation) during use to avoid workpiece scrapping due to incorrect compensation.

4. Fault and Troubleshooting

4.1 What are the causes and solutions for "chattering" during machining?

Causes: ① Excessively high spindle speed or too small feed rate, causing tool vibration; ② Overlong tool with insufficient rigidity (such as slender end mills); ③ Unstable clamping of workpiece or fixture, resulting in displacement vibration during machining; ④ Excessively large depth of cut, exceeding the load capacity of the tool and machine. Solutions: Reduce speed and increase feed rate; replace with tools with higher rigidity (shorten tool extension length); reinforce the workpiece and fixture, add positioning surfaces or auxiliary supports; reduce depth of cut and perform multi-pass cutting.

4.2 How to solve burrs and excessive surface roughness on workpieces?

Causes: ① Tool wear or dull cutting edge, unable to perform smooth cutting; ② Excessively large feed rate or too low speed, leading to uneven cutting; ③ Insufficient cooling, causing sticking and surface scratching; ④ Unreasonable tool path (such as no deceleration at corners). Solutions: Replace with new tools or regrind tools; adjust speed and feed rate (increase speed, reduce feed rate); optimize cooling method to ensure cutting fluid covers the cutting area; modify the programming path, add arc transition or deceleration commands at corners.

4.3 What are the common troubleshooting directions for excessive workpiece dimension deviation after machining?

Troubleshooting Directions: ① Programming Issues: Whether the tool path is incorrect, whether compensation parameters are set correctly (such as wrong input of length compensation value); ② Tool Issues: Whether the tool is worn, whether runout exceeds the standard (detectable with a dial indicator); ③ Fixture Issues: Whether the positioning datum is offset, whether clamping force causes workpiece deformation (measure after loosening the fixture to judge deformation due to clamping); ④ Machine Issues: Whether the machine positioning accuracy is inaccurate, whether the spindle has axial movement (professional calibration required); ⑤ Measurement Issues: Whether the measuring tool is calibrated, whether the measurement method is correct (avoid measuring uncooled workpieces).

5. Cost and Efficiency Optimization

5.1 How to improve the machining efficiency of CNC milling?

Optimization Methods: ① Adopt "high-speed roughing" strategy for rough machining, increase depth of cut and feed rate, reduce cutting times; ② Reasonably plan tool paths to reduce idle travel (such as arranging machining sequence based on the proximity principle); ③ Use combined tools to complete multiple processes at one time (such as combined drilling, reaming, and boring tools); ④ Optimize clamping methods to realize simultaneous machining of multiple workpieces (such as positioning multiple workpieces with jigs for batch processing); ⑤ Regularly maintain machines and tools to avoid downtime due to faults or frequent tool replacement.

5.2 What are the main factors affecting CNC milling processing costs? How to control costs?

Main Factors: Tool consumption (wear, scrapping), cutting fluid consumption, machine energy consumption, labor cost, workpiece scrap rate. Control Methods: ① Select cost-effective tools and extend tool life (such as optimizing cutting parameters and ensuring adequate cooling); ② Use cutting fluid reasonably to avoid waste (wet cooling can be recycled and filtered for reuse); ③ Optimize programming and processes for batch processing, improve machine utilization, and reduce unit energy consumption and labor cost; ④ Strengthen in-process inspection, troubleshoot problems in a timely manner, and reduce scrap rate; ⑤ Regularly maintain machines to reduce fault maintenance costs.

6. Safety and Operation Specifications

6.1 What are the core safety precautions for CNC milling operations?

Core Safety Precautions: ① Check the machine status (spindle, guideway, cooling system) before starting, wear protective equipment (impact-resistant goggles, non-slip shoes, gloves are prohibited); ② Ensure the spindle stops rotating when clamping workpieces and tools to avoid collision; ③ Perform "dry run" before machining to verify the tool path is correct and start cutting only when there is no collision risk; ④ Do not open the machine protective door or touch rotating tools and workpieces during machining; ⑤ Press the emergency stop button immediately and cut off the power in case of emergencies.

6.2 How to perform daily maintenance on CNC milling machines to extend service life?

Daily Maintenance: ① Cleaning: Remove chips and oil stains from machine guideways, spindles, and worktables after daily machining to avoid wear; ② Lubrication: Regularly add lubricating oil to guideways and lead screws to ensure smooth movement of moving parts; ③ Cooling System: Regularly replace cutting fluid and clean filters to prevent clogging; ④ Precision Calibration: Regularly detect machine positioning accuracy and spindle runout, and calibrate in time if deviations are found; ⑤ Electrical System: Keep the electrical cabinet ventilated and dry, avoid dust accumulation, and check the firmness of wire connections.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.