In the field of high-end equipment manufacturing, the hydraulic system, as the core of power transmission, its performance directly depends on the machining accuracy of key components. As the "heart" of the hydraulic valve, the valve core undertakes the precise control function of fluid flow, pressure and direction, and its requirements for dimensional tolerance, geometric accuracy and surface quality reach the micron level. Taking the machining project of high-precision overflow valve core of a large hydraulic equipment enterprise as an example, this paper expounds how CNC turning technology breaks through the bottleneck of traditional machining and achieves the dual goals of mass production and precision control.

I. Project Background and Machining Difficulties

The cooperative partner of this project is a leading domestic construction machinery enterprise, which needs to mass-produce overflow valve cores for pressure regulation in hydraulic systems, with an annual demand of 25,000 pieces. The valve core is made of 6061-T6 aluminum alloy, which has high strength, corrosion resistance and excellent machinability. However, it is prone to deformation during machining, putting forward extremely high requirements for process stability. Combined with the product drawings and actual working conditions, the core machining difficulties are concentrated in three aspects.

First, the precision requirement is strict. The outer diameter of the valve core is φ8mm, the dimensional tolerance must be controlled within ±0.005mm, the roundness and cylindricity tolerance shall not exceed 0.002mm, and the coaxiality error of each stepped cylindrical surface shall be ≤8μm. At the same time, the surface roughness Ra of the matching surface of the valve core shall reach 0.1μm to ensure uniform clearance after assembly with the valve hole and reduce fluid leakage. Second, the structure is complex. The valve core has a stepped structure, including 3 outer circles of different diameters, 2 annular sealing grooves and 1 deep hole (length-diameter ratio 1:12). The positional accuracy between each feature is strictly required, and traditional machining is difficult to balance the coordinated accuracy of multiple processes. Third, the bottleneck of mass production efficiency. Traditional ordinary lathe machining relies on manual control of arc feed, which has high operation difficulty and a scrap rate of up to 8%. The processing time per piece exceeds 4 minutes, which cannot meet the demand of large-scale delivery.

II. Overall CNC Turning Solution

In response to the above difficulties, the technical team adopted an integrated solution of "customized equipment + refined process + full-process inspection", taking the Zhongzhi Jinggong ZTZ series double-spindle CNC lathe as the core machining equipment, combined with precision tooling and intelligent inspection system, to build an efficient machining link.

(I) Equipment and Tooling Configuration

A double-spindle CNC lathe equipped with Siemens 828D CNC system is selected, which has the capability of synchronous machining with double spindles, and can complete the turning of features at both ends of the valve core simultaneously, greatly shortening the process flow time. The equipment adopts an integrally cast high-grade cast iron bed, whose structural design is optimized through finite element analysis, with excellent shock resistance and thermal stability, effectively offsetting the vibration and thermal deformation caused by high-speed cutting. In terms of tooling, a customized spring steel expansion sleeve fixture is used to realize the clamping of the valve core by internal hole positioning. The expansion sleeve is in clearance fit with the internal hole and fixed by top tightening at both ends, avoiding part deformation caused by clamping stress, and the coaxiality positioning accuracy can reach 0.003mm.

(II) Tool and Cutting Parameter Optimization

Tool selection specifically solves the problems of aluminum alloy adhesion and unsatisfactory surface roughness. PCD diamond-coated tools are used for outer circle turning, which have high hardness, strong wear resistance and excellent cutting edge sharpness, reducing cutting force and surface scratches; customized cemented carbide forming tools are selected for annular groove machining, completing groove machining in one feed to ensure groove width and depth accuracy. The cutting parameters are optimized through multiple rounds of trial cutting: the rough machining speed of outer circle is 3500r/min, the feed rate is 0.2mm/r, and the depth of cut is 0.3mm; the finish machining speed is increased to 6000r/min, the feed rate is reduced to 0.08mm/r, and the depth of cut is 0.05mm. At the same time, high-pressure cooling with emulsion (pressure 0.8MPa) is adopted to timely take away cutting heat and inhibit workpiece deformation.

(III) Multi-Process Integrated Machining Process

A four-stage process of "rough turning - semi-finish turning - finish turning - finishing machining" is adopted to realize multi-process automatic integration through CNC programs. First, the double spindles synchronously rough turn the outer circle and steps, remove most of the allowance, and reserve 0.2mm finish machining allowance; then semi-finish turn each outer circle feature to correct geometric errors and lay the foundation for finish machining; in the finish machining stage, constant cutting speed mode is adopted, combined with tool nose radius compensation function, to accurately control outer circle precision and surface quality, and complete annular sealing groove machining simultaneously; finally, honing process is used for finishing the deep hole and matching surface to meet the design requirements of surface roughness. The whole machining process requires no manual intervention, and the processing cycle per piece is shortened to 1.8 minutes.

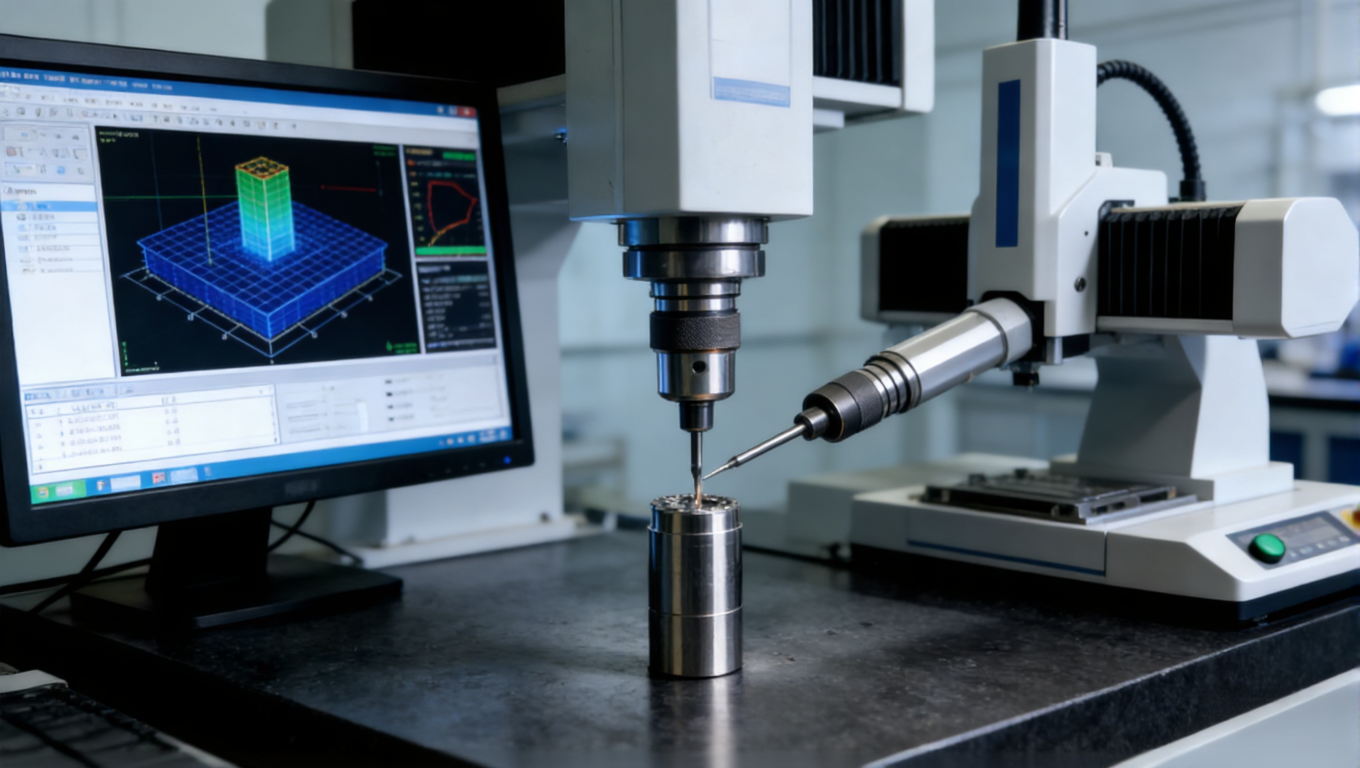

(IV) Full-Process Inspection Control

A dual inspection system of "in-process self-inspection + finished product full inspection" is established. On-line probe inspection is adopted between processes. The probe integrated in the CNC lathe can automatically measure key dimensions, feed back data in real time and automatically compensate tool wear through the CNC system; coordinate measuring machine is used for finished product inspection to comprehensively detect dimensional accuracy and geometric tolerance. 5% of samples are randomly selected from each batch for destructive testing to verify the integrity of the internal structure and ensure stable product qualification rate.

III. Application Effects and Industry Value

After three consecutive months of mass production verification, the solution has achieved triple breakthroughs in machining precision, production efficiency and cost control. In terms of precision, the key dimensional tolerance of the valve core is stably controlled within ±0.003mm, the roundness and coaxiality errors are both less than 0.002mm, and the surface roughness Ra ≤0.08μm, fully meeting the assembly requirements of the hydraulic system, and the product defective rate is reduced from 8% to 0.3%. In terms of efficiency, the processing cycle per piece is shortened by 55%, the single-shift output is increased from 300 pieces by traditional process to 750 pieces, and the annual output can reach 30,000 pieces, exceeding the customer's demand. In terms of cost, automated machining reduces labor input by 80%, extends tool service life by 40%, and reduces comprehensive manufacturing cost by 32%.

This case fully verifies the core enabling value of CNC turning technology in precision valve core machining. Through the in-depth adaptation of equipment and processes, it breaks the dependence of traditional machining on manual skills and realizes the unification of micron-level precision and large-scale production. In high-end manufacturing fields such as hydraulic components, auto parts and aerospace, such solutions can be widely applied to the machining of precision parts such as shafts and sleeves, providing a reference paradigm for the industry to transform towards high precision, high efficiency and low cost. In the future, with the in-depth integration of 5-axis CNC turning technology and intelligent inspection system, it will further break through the machining bottleneck of complex structural parts and promote the upgrading of the precision manufacturing industry.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.