Integrated build path from ideas to delivery

Nimble partnered with Mastars to go from concept to boxed units through one integrated build path. We Mastars owned DFM, rapid prototyping, tooling, and pilot through mass production, coordinating plastics, metals, electronics, and testing under one system. We tackled system-level motion precision and deposition accuracy, aligned mechanisms with real-world producibility, and kept cost control from day one.

Mastars turns bold ideas into shipped, revenue-creating products with an orchestrated, end-to-end supply chain.

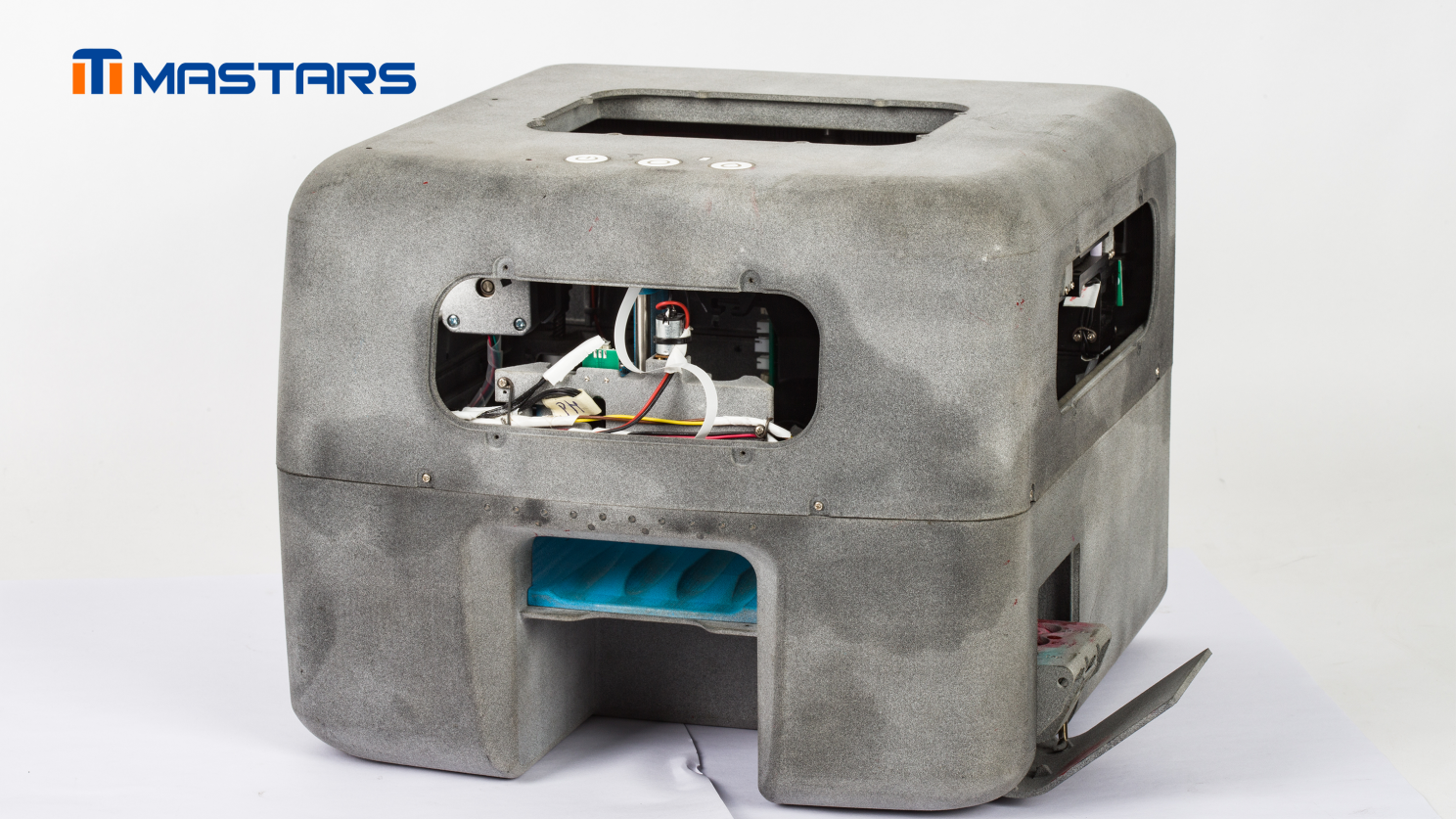

The manicure machine during prototyping

Micron-level motion, vibration, and durability constraints

The prototype phase lasted 12 months, with the client on-site and sharing test reports.

Tough issues during prototyping are:

- Tolerance stack-ups: control variation with GD&T, CMM, and preload.

- Lead-screw–motor matching: compensate pitch, calibrate endpoints, minimize backlash.

- Motor vibration control: damp resonance, ensure micro stepping linearity, keep paths stable.

- Durability under continuous duty: manage wear, compensate thermal drift, close loop with SPC.

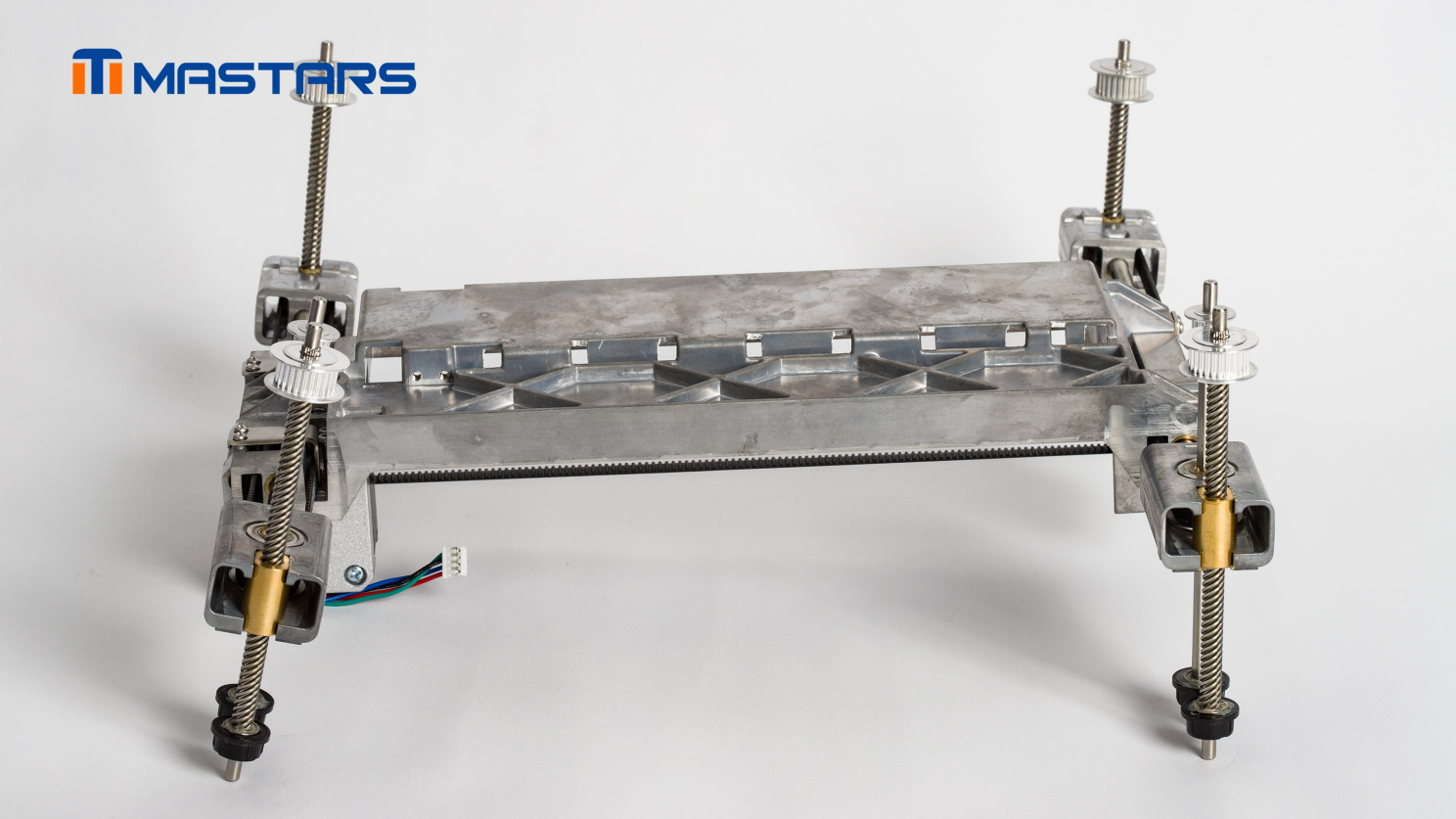

Because the lead screw and motor define motion authority, polish deposition demanded precise path control while suppressing motor vibration error.

Client on sites discussing engineering issues

Buyer-first low-cost process solves prototype gaps

From the buyer’s seat, we chose a mature, lower total-cost route—switching from CNC-machined lead screws to thread rolling—which improved surface finish, pitch repeatability, and nut fit, reduced backlash, smoothed motion, and closed prototype accuracy gaps without added complexity.

A standardized rolling supply base, shorter cycles, simpler gauging, and line controls across machining, molding, assembly, and EOL turned a cost-down decision into a reliability win.

Core component: a change in the lead screw and motor that enabled mass production

Lower cost, faster cycles, stable quality

Development lead time is shorter than peers. Quality stays stable across lots. Customer cost dropped ~10%. Annual shipments reached ~20,000 units.

An integrated, digital supply chain lets entrepreneurial companies and SMEs move from prototype to volume with less risk and tighter timelines.

Ready to serve clients and users across the world

End-to-end certainty for ambitious teams

Mastars delivers certainty from design through prototype, and pilot through mass production. Integrated capabilities and certified systems compress time, control cost, and raise yield—so smaller teams can scale confident product roadmaps.

Final product, photo credit by Nimble

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.