Background

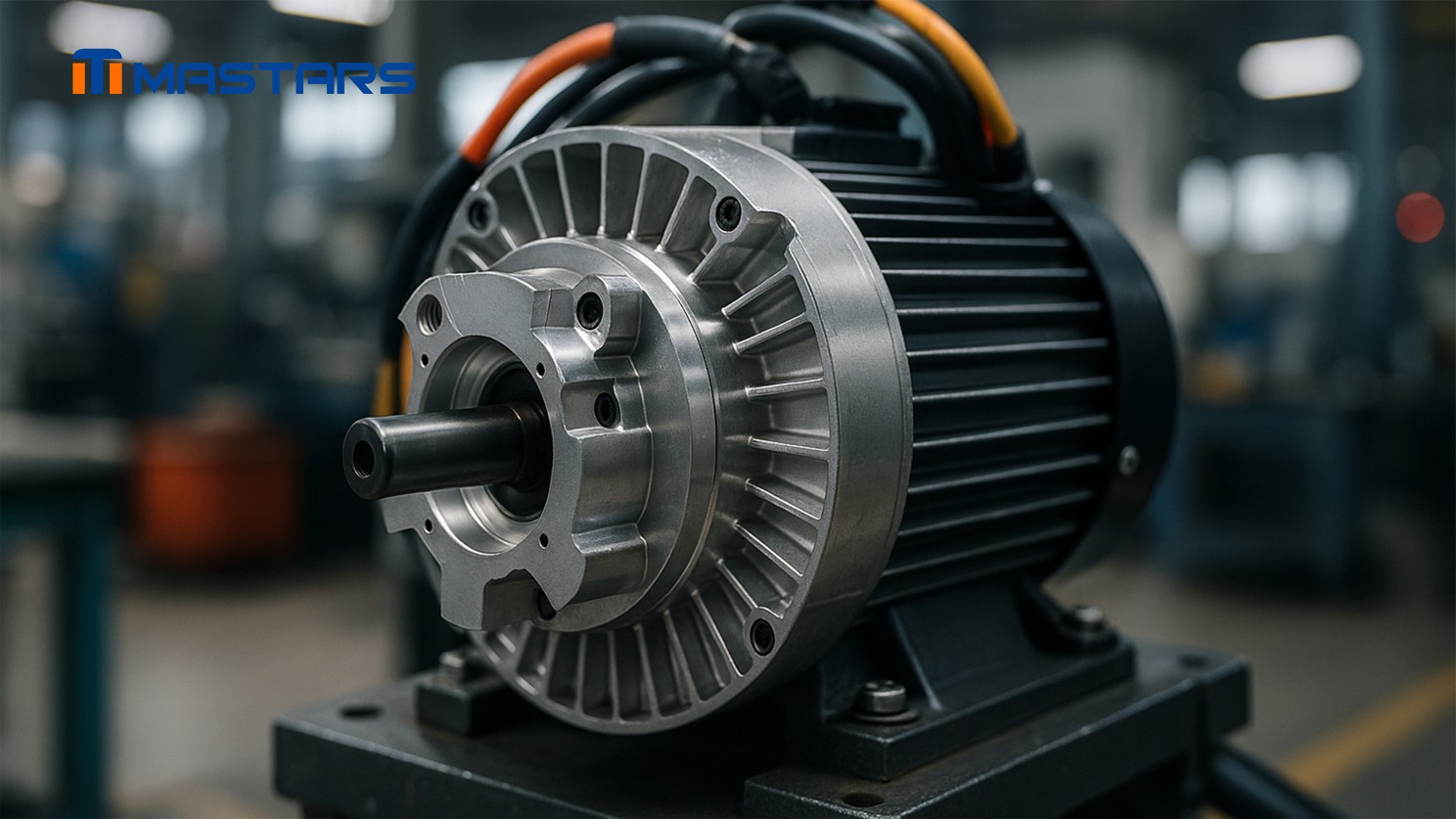

In prototyping and pilot builds, five-axis CNC machining is essential. It finishes complex geometry in fewer setups, protects datum integrity and coaxially, and holds thin-wall fins without distortion. For automotive e-drive, robotics, HVAC blowers, and medical/lab devices, five-axis lets teams validate manufacturability—bearing seats, sealing lands, and mounting faces—before committing to tooling.

The Challenge

Five-axis prototypes carry risk and cost: long reach on thin ribs can chatter; weak fixturing distorts parts; re-clamps break datum control; unverified toolpaths scrap billets; tool wear harms finish and bearing fits. Without DFM, modular fixtures, in-process probing, and CMM inspection, unit cost and schedule drift fast.

Mastars Solution

Mastars couples CNC and five-axis precision with a production-style route: upfront DFM, alloy selection (e.g., 6061-T6/6082-T6), rigid modular fixtures, and verified CAM toolpaths. In-process probing holds bores, faces, and fin thickness; CMM verifies CTQs. Deburring and ultrasonic cleaning are controlled; anodizing is available for corrosion and cosmetic stability. Traceable inspection reports ship with every lot.

Benefits

What you gain with five-axis motor components made by Mastars

✅ Fewer setups and stronger datum integrity for better coaxiality and alignment.

✅ Stable thin-wall and fin machining—lighter parts with effective cooling.

✅ Repeatable bearing-seat and sealing-land finishes, reducing noise and wear.

✅ Modular fixturing and proven CAM keep small-batch cycle time and costs steady.

✅ Documentation and inspection aligned to production, ready to scale.

Use Cases

Mastars processes and manufacturing solutions involved in producing this product are also applicable to the following scenarios:

- Automotive e-drive and auxiliary motors

- Robotics and industrial automation actuators

- HVAC and appliance blower housings

- Medical and laboratory equipment drives

- Light-industrial pumps, compressors, and rotating assemblies

Mastars——world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.