Background

Flite is a high-end electric hydrofoil surfboard brand, where every visible metal part must look as refined as it performs. The wing mast works in salt water, has frequent impacts, and still has to present a clean, premium surface that fits the overall design language. Riders expect durable structure, but also color options and branding that feel custom rather than generic. That “premium feeling” comes from controlled material selection and repeatable surface finishing, not only from the CAD model.

For a manufacturer, this means real one-stop capability: from alloy machining to polishing, blasting, anodizing, and laser marking, all aligned with ISO 9001 and IATF 13485-based quality systems to keep quality stable and lead time short in serial builds.

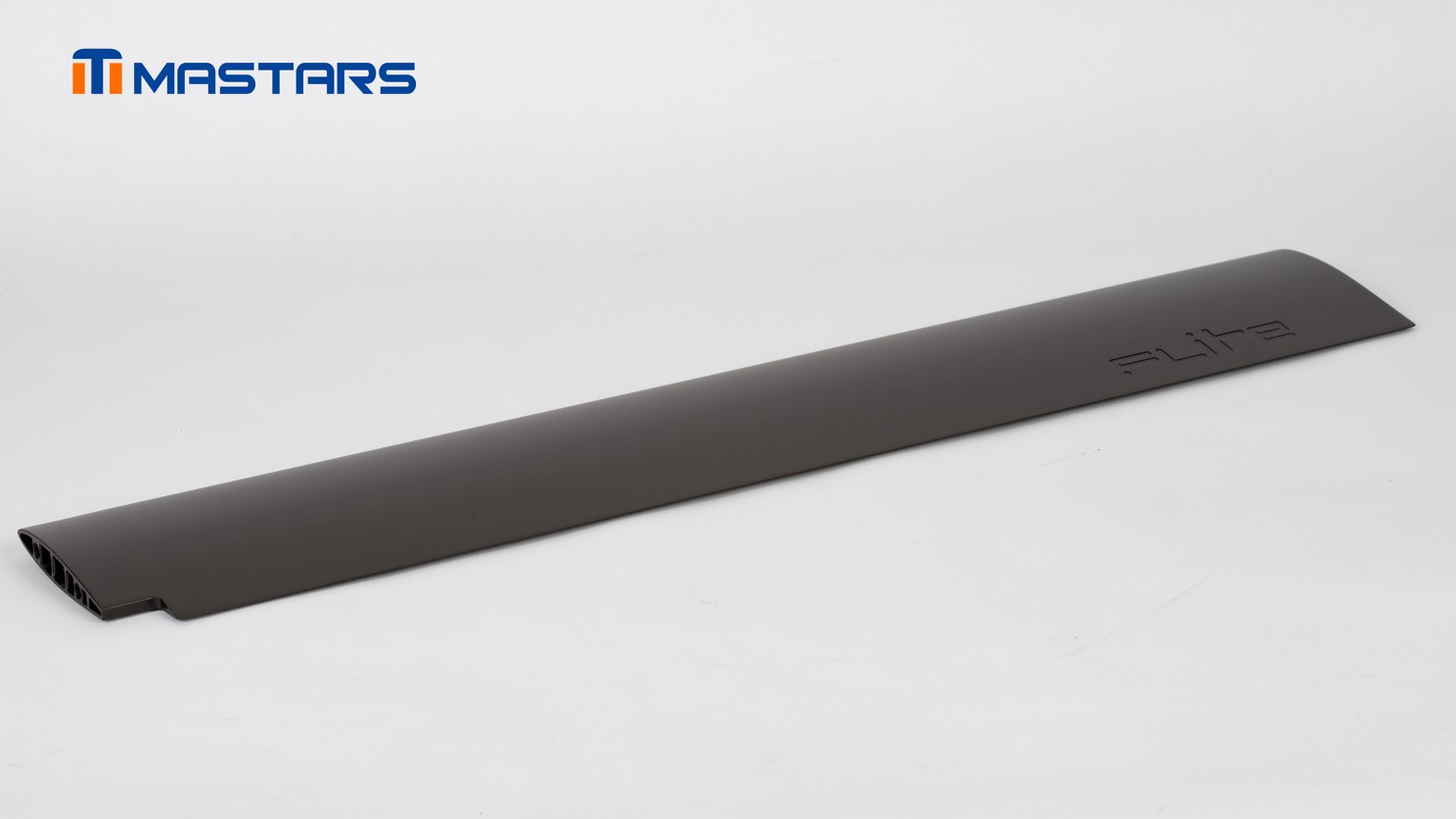

Full-length CNC-machined and hard anodized wing mast ready for assembly on premium e-foil boards.

The Challenge

For a premium product, standard catalogue finishes are not enough. The mast requires a slim hydrodynamic profile, precise threaded interfaces, and a long, flat surface that will show any small defect. At the same time, the customer needs options in color, texture, and logo layout to support different board models and limited editions. That pushes the supplier to offer a wide library of post-processing routes while still keeping parameters under control.

If machining, polishing, blasting, anodizing, and marking are split across several manufacturers, it becomes hard to control colour consistency, gloss level, corrosion resistance, and dimensional stability along the full length of the mast. Engineering changes also become slow and risky when every new finish combination means re-qualifying another external partner.

Laser-etched branding on anodized surface highlights fine control of texture and color

+

Mastars Solution

We provide a single process chain for the wing mast based on CNC machining of AL 6061-T5, followed by polishing, controlled sand blasting, hard black anodizing, and laser etching. The structural profile and internal ribs are first machined to tight tolerances, including critical screw threads and alignment features for the board and foil assembly. The surfaces are then polished to remove machining marks and prepare a uniform base.

A fine, repeatable sand blast gives the required matte texture without rounding edges or changing aerodynamic form, and can be tuned for different visual effects. After that, the parts go through hard anodizing to build a corrosion-resistant, wear-resistant oxide layer suitable for long-term salt-water exposure. Logos marks are finally added by laser etching, which preserves coating integrity and allows small design changes without new tooling.

All steps are planned and inspected under ISO and IATF quality controls, so color, thickness, and dimensions stay consistent from prototypes to small and medium-volume batches, even when finish recipes vary.

Three AL 6061-T5 mast extrusions with different anodized finishes showing consistent internal rib machining.

Benefits

This project shows how Mastars uses one-stop metal processing and rich finishing options to simplify premium product development.

✅ One-stop manufacturing service for machining, polishing, blasting, anodizing, and laser marking reduces handovers and schedule risk.

✅ Stable color and texture across batches due to in-house process and test panels.

✅ Hard anodized AL 6061-T5 provides a good stiffness-to-weight ratio and corrosion resistance for marine environments.

✅ Consistent quality records and inspection reports support long-term series supply under ISO 9001 and IATF frameworks.

In-house pretreatment of aluminum parts before anodizing ensures and corrosion resistance in salt water.

Use Cases

The same combination of customized surface finishing and one-stop manufacturing supports other high-end, design-driven products.

- Lifestyle and sports hardware: bike and scooter components, control levers, and structural bars that need durable colors and branding.

- Consumer electronics and equipment: aluminum housings, stands, and control panels with fine textures and sharp laser-marked graphics.

- Architectural and interior elements: visible brackets, trims, and handrail profiles where anodized colors must match across many lengths.

Finished e-foil board with machined and finished wing mast as a visible structural design element.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.