Reliable manufacturing for complex stationery parts

How do you find a manufacturing partner who can turn a flexible stainless steel clip‑and‑ruler design into reality, meet ISO 9001 standards, and align with a sustainability mission? An Australian design brand approached Mastars with this challenge. Their portable drawing boards use recycled PET bottles and require a compact clip that could clamp ten A3 sheets and double as a 130 mm ruler. They needed more than a supplier; they needed an end‑to‑end manufacturing service capable of engineering, prototyping, small‑batch production, and quality assurance.

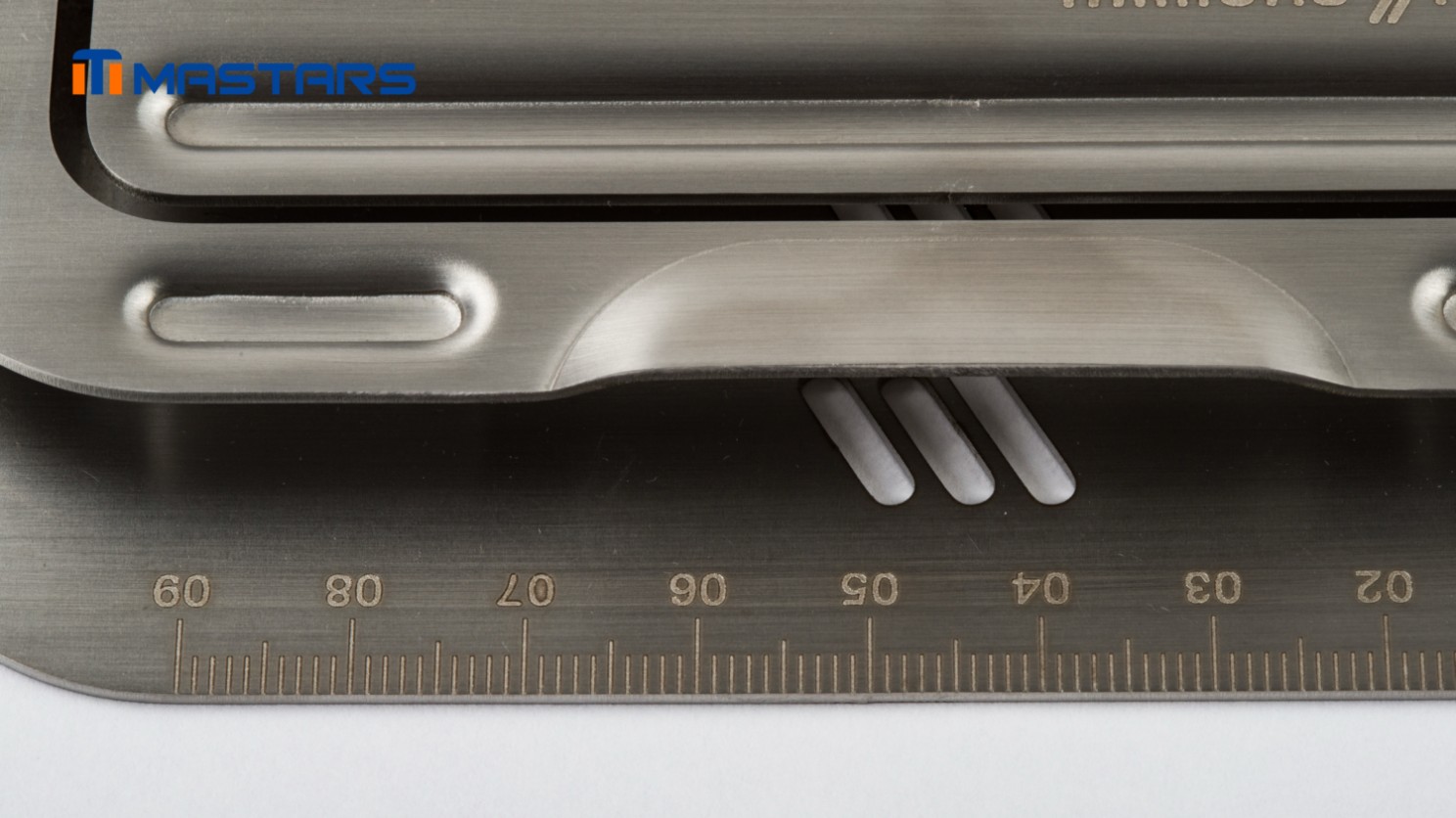

The brief was strict. The clip had to be made from tempered stainless steel to resist corrosion and be fully recyclable. Scale markings needed to be permanent and accurate, and the final part had to integrate seamlessly with the board’s living‑hinge design. Mastars were asked to take the concept through design‑for‑manufacture, validate the process, produce prototypes, and deliver low‑volume batches while providing full traceability and calibration certificates.

Sett of stainless steel ruler-clips showing finish options and low-volume consistency.

One‑stop metal processing services and expertise

Mastars began by reviewing the client’s CAD files and suggesting improvements for manufacturability. Stainless steel bending is tough because of high yield strength, work hardening, and significant springback. Mastars’ engineers adjusted bend radii and grain orientation to minimise cracking and compensator springback. They then selected 304/301 stainless steel for its toughness and formability, and procured certified material from trusted mills. Their prototyping team used precision stamping and CNC bending equipment to form the clip profile, iterating quickly thanks to digital tooling.

For the scale, Mastars recommended photochemical etching. This process coats the sheet with a photoresist, transfers the ruler pattern via UV light, and removes exposed metal with an etchant. Etched markings are recessed and black‑filled, ensuring legibility and preventing wear. Because chemical etching uses digital masks, design changes are quick, and there is no tool wear, making it ideal for low‑volume runs. After etching, Mastars laser‑marked the client’s logo, deburred the edge,s and applied a brushed finish to match the board.

Quality management is at the core of Mastars’ service. The company operates under ISO 9001 and performs in‑process inspections after each operation. Stainless steel rulers from reputable manufacturers use grade 301 stainless steel and permanently etched graduations to guarantee durability and precision. Mastars use similar practices and issue certificates traceable to national standards such as NIST. They also manage logistics, packaging, and export documentation, shipping the finished clips to the client’s distribution centre.

Advantages of partnering with Mastars

By engaging Mastars, the client gained more than a component; they obtained a comprehensive service that reduced risk and time to market.

✅ Design for manufacture: expert review to optimise bending and etching for stainless steel.

✅ Integrated processes: in‑house stamping, bending, chemical etching, and surface finishing enabled one‑stop production.

✅ Certified quality: ISO 9001 workflow with traceable calibration documents.

✅ Low‑volume flexibility: digital tooling and rapid iteration suitable for prototypes and small batches.

Drawing board with this project, the premium stainless ruler-clips, holding loose sheets crease-free. Photo credit to this client.

Apply these services to your industry

The combination of design support, chemical etching, CNC machining, and rigorous quality control isn’t limited to drawing boards. Many industries require precise, low‑volume metal components and a manufacturing partner who can manage the entire process.

Other industries and products that can benefit from Mastars’ services include:

- Compact measuring devices and laboratory gauges

- Luxury packaging components with integrated functionality

- Consumer electronics clips and precision hinges

Do you need a partner who can translate your concept into a durable, sustainable component? Whether you’re designing a niche tool or a premium accessory, Mastars’ one‑stop manufacturing services can help. Share your design and requirements; we’ll tailor the process, manage quality, and deliver to your schedule.

Mastars, the most trusted and reliable one‑stop services partner for low‑volume digital manufacturing worldwide!

Mastars, the most trusted and reliable one‑stop services partner for low‑volume digital manufacturing worldwide!

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.