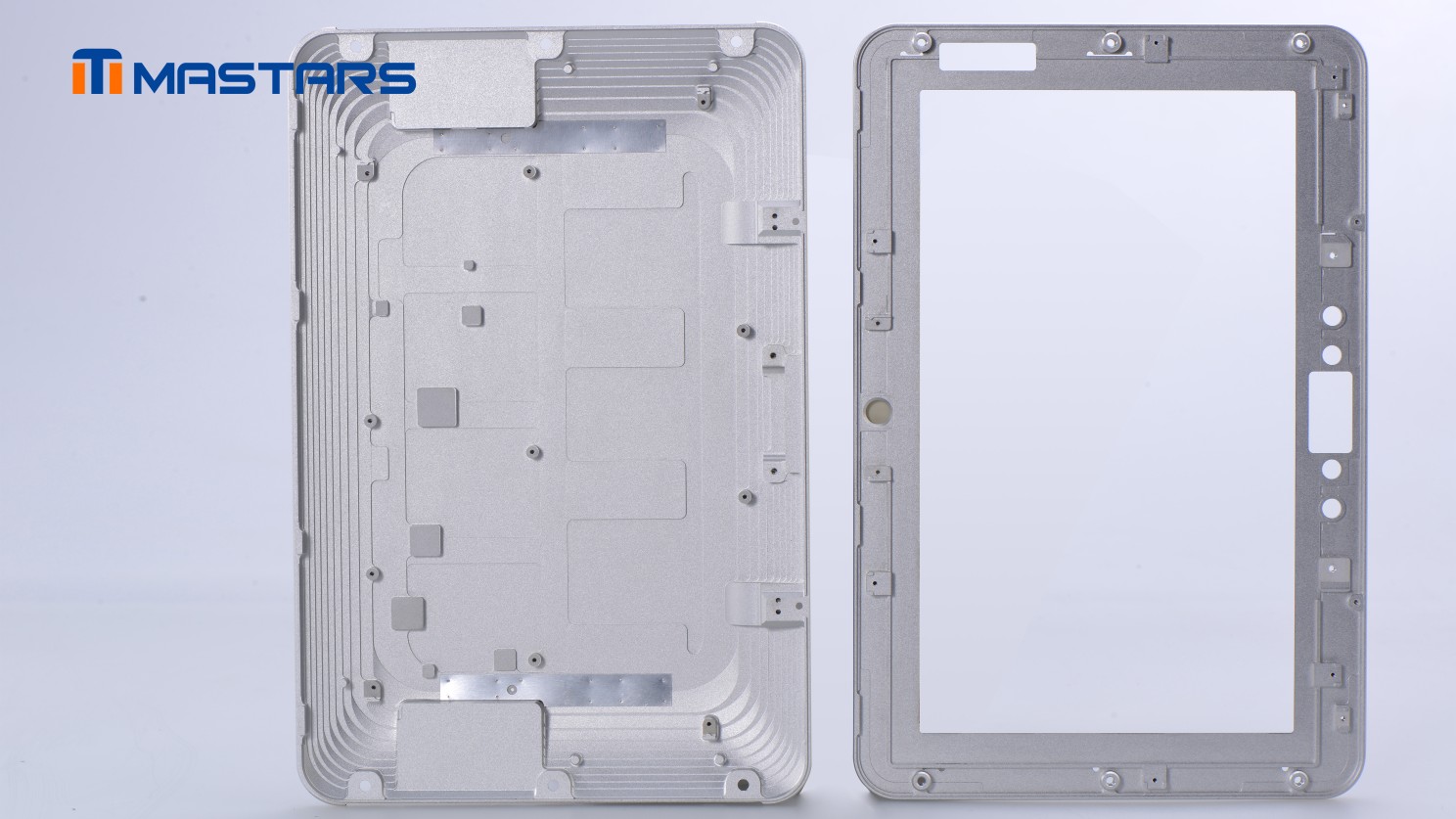

When the mechanical fit must stay true

How do you machine a thin-wall unibody housing so it stays flat, keeps hole location, and still looks clean after anodizing? This is difficult because a small distortion or datum shift shows up fast during assembly.

The client is a product team from the United States. They needed a prototype to validate fit, feel, and internal mounting points before the next step. Main requirements were one-piece 5-axis CNC precision machining, strict control of key interfaces, and an anodized finish that does not break the mechanical fit.

Precision milled interrior

A controlled path from cut to finish

The main risk is stability: thin walls, long spans, and many pockets can cause warp, vibration marks, and shifting reference points between setups. If that happens, the prototype is no longer reliable for fit evaluation.

Mastars used a controlled build route: rigid fixturing, balanced material removal, and datum-first machining so later features reference the correct faces. Critical features were checked during machining, then anodizing was planned with masking and surface protection to help keep the assembly fit.

What the prototype enabled for decisions

Client outcome: a prototype housing that assembled cleanly and kept a consistent anodized appearance.

✅ Fewer fit surprises during first trial assembly

✅ Better hole alignment for brackets and internal modules

✅ Cleaner edges and corner control on visible surfaces

✅ More stable dimensions across both sides

✅ Faster design decisions with a buildable reference part

Where this method fits with other products

If you are in another industry, the same risks still apply: thin walls, stacked tolerances, and visible surfaces.

This approach can also help products in:

- Medical devices: handheld diagnostic terminal enclosures

- Factory automation: HMI frames

- Logistics: rugged handheld or tablet back covers

- Energy and utilities: field data-logger enclosures

- Marine: navigation display housings

Do you have a part that needs one-piece 5-axis CNC plus anodizing, but still must assemble right the first time? Which factor drives your risk today: material, wall thickness, or tolerance zones?

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.