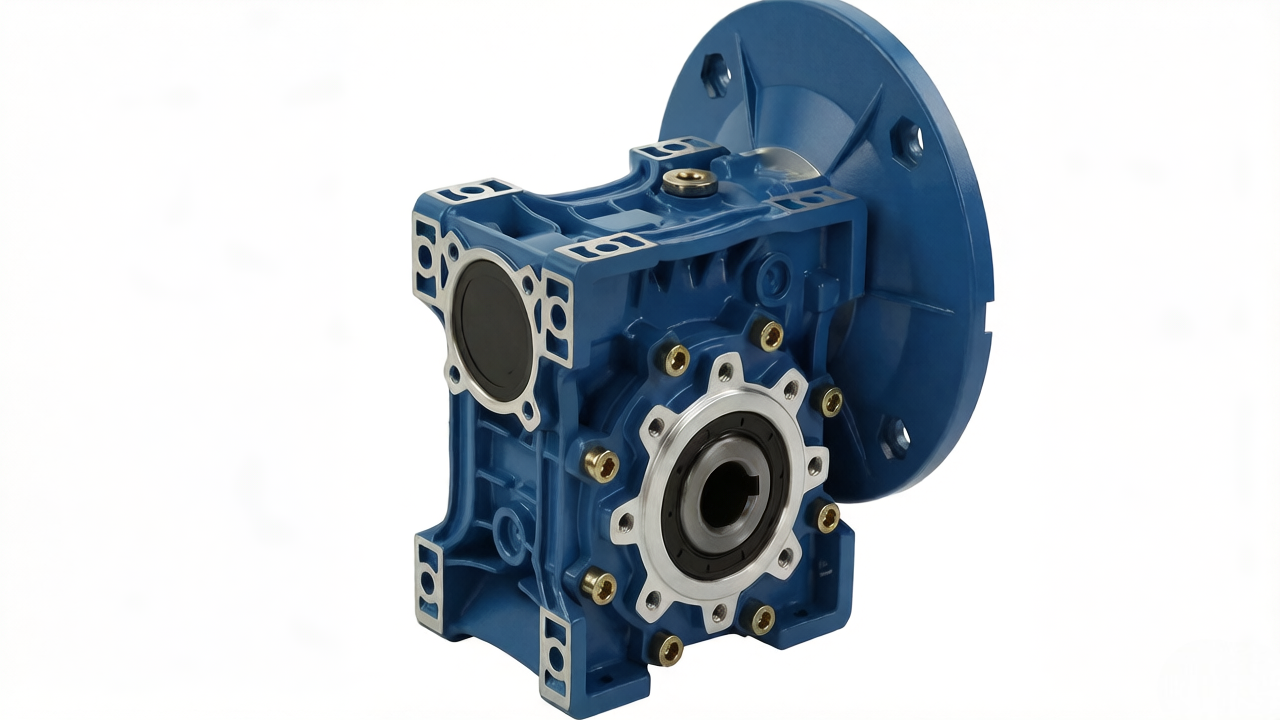

With the global promotion of intelligent and mechanized agriculture, the demand for high reliability, durability, and efficiency of agricultural machinery has become increasingly prominent. As the "power core" of rotary tillers, the gearbox housing bears the key functions of power transmission, load bearing, and protection of internal components. It must withstand harsh working conditions such as high-intensity vibration, dust erosion, and alternating temperature changes in farmland environments. Mastars, relying on its core capabilities in precision machining, customized material supply, and integrated supporting services, has long been deeply involved in the field of agricultural machinery parts manufacturing, providing one-stop solutions for global agricultural machinery enterprises and laying a solid foundation for the stable operation of agricultural production equipment.

I. Core Demands of Rotary Tiller Gearbox Housings and Mastars' Business Positioning

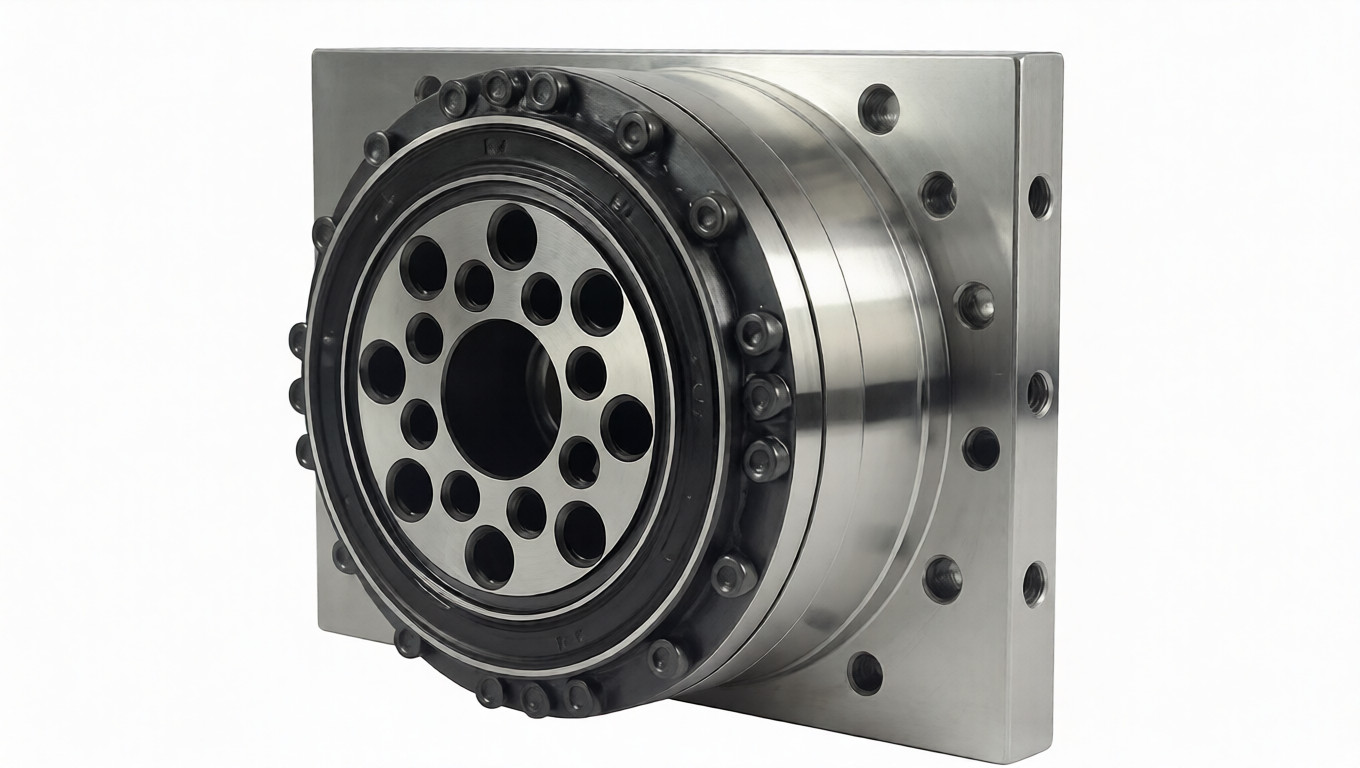

The rotary tiller is a core equipment for farmland soil preparation, and its gearbox housing is a critical structural component that connects the engine, transmission gears, and tillage blades. The harsh working environment of agricultural machinery and the high-intensity operation requirements impose extremely strict standards on the manufacturing of gearbox housings. Mastars has targeted these core demands and formed a systematic solution integrating "material customization + precision machining + surface treatment + quality inspection" based on its own business advantages.

The core manufacturing requirements of rotary tiller gearbox housings mainly include four aspects, which are also the key areas where Mastars exerts its technical advantages:

• High structural strength and fatigue resistance: The housing needs to bear continuous torque transmission and alternating loads during operation, requiring the material to have high tensile strength (≥600MPa) and excellent fatigue resistance. Mastars provides high-quality alloy structural steel (such as 20CrMnTi) and high-strength aluminum alloy materials that meet the standards of agricultural machinery, effectively avoiding cracks and deformation under long-term high-load operation .

• Strict dimensional accuracy and assembly compatibility: The gearbox housing has complex internal structures such as gear chambers, bearing seats, and oil passages, with the positional accuracy of key holes and matching surfaces required to be controlled within ±0.02mm. Mastars achieves precise control of these tolerances through advanced CNC machining technology, ensuring perfect matching with internal gears, bearings, and other components to avoid power loss and abnormal noise .

• Excellent corrosion and wear resistance: Farmland environments are often accompanied by moisture, soil particles, and chemical fertilizers, so the housing surface must have good corrosion resistance and wear resistance. Mastars matches targeted surface treatment processes such as galvanizing, powder coating, and electrophoretic coating, ensuring that the product can pass 500-hour salt spray tests and maintain stable performance in harsh farmland environments .

• High batch consistency and cost-effectiveness: Agricultural machinery production has the characteristics of mass production, requiring parts to have stable consistency while controlling manufacturing costs. Mastars optimizes the production process through intelligent equipment and lean management, balancing production efficiency and cost control to meet the large-scale supply needs of agricultural machinery enterprises .

Traditional manufacturing processes such as ordinary casting and machining are difficult to fully meet the above comprehensive requirements. Mastars' integrated solution of "material customization + precision machining" has become a core support for high-quality production of rotary tiller gearbox housings.

II. Core Applications of Mastars' Business in Gearbox Housing Manufacturing

Mastars integrates its core businesses such as precision machining, material supply, and customized supporting services into the entire production process of rotary tiller gearbox housings, forming a complete set of solutions covering from blank manufacturing to finished product delivery, and its core applications are concentrated in the following aspects:

(I) Material Customization: Laying the Foundation for Product Reliability

Material selection is the first key link in the manufacturing of gearbox housings, and Mastars has formed a professional material supply system based on the working characteristics of agricultural machinery. For heavy-duty rotary tillers (above 100 horsepower), Mastars mainly provides alloy structural steel such as 20CrMnTi and 40Cr, which are produced through ultra-pure smelting processes, with oxygen content controlled below 12ppm and excellent hardenability and toughness, effectively improving the bearing capacity and fatigue life of the housing . For medium and small horsepower rotary tillers that pursue lightweight, Mastars supplies high-strength aluminum alloys (such as 6061-T6), which not only reduce the overall weight of the equipment (reducing fuel consumption by 8-12%) but also have good machinability and corrosion resistance, meeting the lightweight development trend of agricultural machinery .

In addition, Mastars can also customize material formulas according to the special needs of customers. For example, for rotary tillers used in saline-alkali land areas, it adds corrosion-resistant elements such as molybdenum and nickel to the steel material to further improve the corrosion resistance of the housing; for high-temperature working environments in tropical regions, it optimizes the material's thermal stability to avoid performance degradation caused by high temperatures.

(II) Precision Machining: Core Technology to Ensure Manufacturing Accuracy

Precision machining is the core competitiveness of Mastars, and it has configured a professional machining equipment portfolio for the structural characteristics of rotary tiller gearbox housings. For the complex structure of the housing (with multiple holes, cavities, and matching surfaces), Mastars adopts large horizontal machining centers (similar to the FF-1250H L series) equipped with HSK-A100 high-speed spindles and two-axis rotary worktables, which can realize multi-surface integrated processing of large workpieces, significantly shortening the production cycle while ensuring machining accuracy . The spindle speed of the equipment can reach up to 15,000rpm, and the repeated positioning accuracy is ±0.01mm, which can effectively guarantee the dimensional accuracy of key holes and matching surfaces of the gearbox housing.

In the machining process, Mastars optimizes the cutting parameters and tool paths according to different materials. For alloy steel housings, it adopts high-hardness carbide tools and high-speed cutting technology to improve machining efficiency while reducing tool wear; for aluminum alloy housings, it uses diamond-coated tools and low-pressure holding technology to avoid material deformation and burr generation. At the same time, Mastars integrates MES production management systems to real-time monitor machining data, dynamically correct machining errors, and ensure the consistency of batch production.

(III) Surface Treatment and Quality Inspection: Closing the Loop on Product Reliability

To enhance the corrosion and wear resistance of gearbox housings, Mastars matches targeted surface treatment processes according to customer needs and application scenarios. For general farmland environments, it adopts powder coating technology, with the coating thickness controlled at 60-80μm, ensuring good adhesion (grade 0 in cross-cut tests) and wear resistance; for harsh environments such as humid and saline-alkali land, it uses electrophoretic coating + galvanizing composite technology, which can double the corrosion resistance of the product and extend the service life by more than 30% .

Quality inspection is an important link to ensure product quality. Mastars has established a strict quality inspection system covering the entire production process. After machining, it uses three-coordinate measuring instruments to conduct full-size inspection of key dimensions; after surface treatment, it conducts salt spray tests, adhesion tests, and wear tests; finally, it conducts assembly tests with matching components to ensure that the product fully meets the customer's assembly requirements and performance standards. All products must pass ISO 9001 quality system certification and agricultural machinery industry standards before leaving the factory.

III. Application Cases: Mastars Empowers Agricultural Machinery Enterprises to Improve Quality and Efficiency

In practical industrial applications, Mastars' integrated solution for gearbox housing manufacturing has been widely recognized by global agricultural machinery enterprises, helping customers solve key technical problems and improve production efficiency and product quality.

For example, Mastars once provided customized gearbox housing manufacturing services for a well-known global agricultural machinery enterprise (similar to MASCHIO Group) that specializes in producing rotary tillers. The customer's product is a 120-horsepower heavy-duty rotary tiller, which requires the gearbox housing to have high strength, high precision, and excellent corrosion resistance, while requiring a monthly supply of 2,000 sets. Faced with these demands, Mastars customized 20CrMnTi alloy structural steel materials, adopted large horizontal machining centers for integrated processing, and matched powder coating surface treatment technology. After optimization, the product's fatigue life was increased by 25%, the machining cycle was shortened by 30%, and the batch pass rate reached 99.5%, fully meeting the customer's production needs. The product has been widely used in farmland soil preparation operations in Europe, America, and other regions, and has won high recognition from customers .

In addition, Mastars also cooperated with a domestic agricultural machinery enterprise to develop gearbox housings for small and medium-sized rotary tillers. By adopting high-strength aluminum alloy materials and optimizing the CNC machining process, the weight of the housing was reduced by 15%, and the manufacturing cost was reduced by 10%, helping the customer's products gain significant competitive advantages in the market. The products have passed the national agricultural machinery product quality certification and are exported to Southeast Asian countries, providing cost-effective solutions for local agricultural mechanization.

IV. Future Trends: Mastars' Layout in the Upgrade of Agricultural Machinery Parts Manufacturing

With the continuous development of intelligent agriculture and the upgrading of agricultural machinery industry, rotary tiller gearbox housings are developing in the direction of lightweight, integration, and intelligence. Mastars will further integrate its core business advantages and promote the innovation and upgrading of manufacturing technology to meet new market demands.

In terms of material innovation, Mastars will focus on the research and development and application of high-performance bio-based materials and high-strength lightweight alloys, further reducing the weight of gearbox housings while improving their environmental friendliness and reliability. In terms of process upgrading, it will integrate digital twin technology into the machining process, build virtual machining scenarios to realize real-time simulation and optimization of the production process, predict and avoid defects in advance, and improve production efficiency and product yield. At the same time, Mastars will expand the application of intelligent detection technology, equip production lines with industrial cameras and online detection systems to realize 100% full inspection of products, ensuring zero defective products entering the market .

In addition, Mastars will further deepen the integration of its business with the agricultural machinery industry, expand its product range from gearbox housings to other core parts such as rotary tiller blades and transmission shafts, and provide more comprehensive one-stop solutions for agricultural machinery enterprises. It will also actively respond to the global "dual-carbon" strategy, optimize production processes, reduce energy consumption and environmental pollution, and promote the green development of the agricultural machinery parts manufacturing industry.

Conclusion

As a core component of rotary tillers, the gearbox housing's manufacturing quality directly determines the operational stability and service life of agricultural machinery. Mastars, relying on its core business advantages such as precision machining, material customization, and customized supporting services, has effectively met the strict requirements of agricultural machinery enterprises for gearbox housing production, and has become a reliable partner in the global agricultural machinery parts manufacturing field.

From material selection to precision machining, from surface treatment to quality inspection, Mastars has always adhered to the concept of "quality first, customer-centric", continuously optimized solutions and improved technical capabilities. In the future, with the continuous advancement of agricultural mechanization and intelligence, Mastars will continue to deepen technological innovation, expand business layout, and play a more critical role in the field of agricultural machinery parts manufacturing, contributing to the development of global intelligent agriculture and the improvement of agricultural production efficiency.

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.