Recently, the 2022 World Badminton Championships in Tokyo, Japan, are being fiercely contested, and the rackets of the world's top players have undoubtedly become the object of attention. So, do you know how badminton rackets are made? There is no doubt that the first thing that should come to mind when it comes to mass-produced products is the use of molds, and badminton rackets are precisely what is used in mold processing.

The production of badminton racket is divided into a total of nine steps

1. Carbon fiber prepreg

Raw materials used: (1) Carbon fiber yarn bundle. (2) Epoxy resin. (3) butanone MEK (dilution with) (4) release paper

Operation method: In the weaving machine, carbon fiber yarn bundle dipped, pre-deployed concentration of epoxy resin, through the roller weave into cloth, attached to the release paper, cut the appropriate angle, and then rest about 2-3 angels MEK evaporated, and then the next process.

2. Preparatory molding

Material used: 1. Carbon weave prepreg section 2. Nylon duct

Operation method: After cutting the carbon fabric into appropriate size layers, wrap the nylon duct in the inner layer and roll it into strips, with appropriate reinforcement at the joints, and measure a certain diameter to complete.

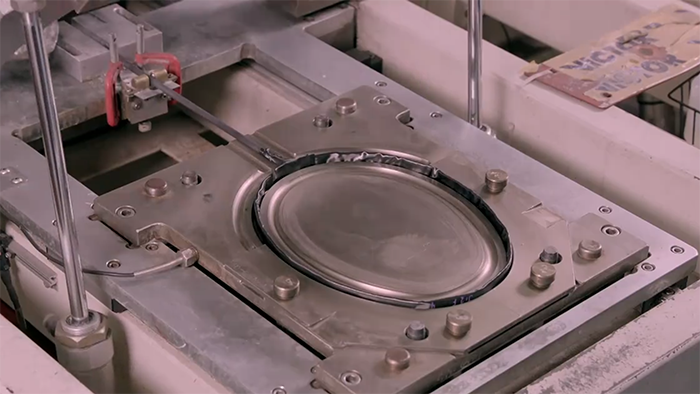

3. Hot press molding

Raw material: Pre-formed carbon material

Operation method: Place the rolled carbon fiber material in the mold and send it to the hot pressing furnace for heating, and use the air compressor to pump in the air to a certain pressure for the reserved nylon air duct.

4. Inspection of the quality of the first embryo

After the embryo is formed, it must undergo a strict inspection before continuing the processing of the next section to ensure comprehensive quality assurance.

Inspection content: whether the appearance is damaged, whether the structure is formed abnormally, whether the weight and balance point meet the specification. The most important thing is whether the strength and pressure resistance are up to standard, and each racket's initial embryo must undergo a pressure test for strength.

5. Drilling thread holes

After passing the inspection, we will drill the holes one by one using the drilling mold and high carbon steel drill bit. The operator must be careful, if there is any error in one hole, the whole racket will be scrapped!

6. Grinding

Grinding before painting can increase the surface brightness and smoothness when painting, but excessive polishing may damage the structure of the surface layer of the racket.

7. Painting

Painting is the same as wearing clothes, and the design of color and pattern is the most important, but also according to personal preference, so the industry has various designs to attract consumers.

8. Assembly

After the finished racket is painted, it is punched with a stamping machine, cut neatly, adjusted for weight and balance, then wrapped with the racket grip and pressure tested once more.

9. Packing

The finished racket will be packaged according to the customer's requirements, with accessories and racket cover attached, and then boxed for shipment.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.