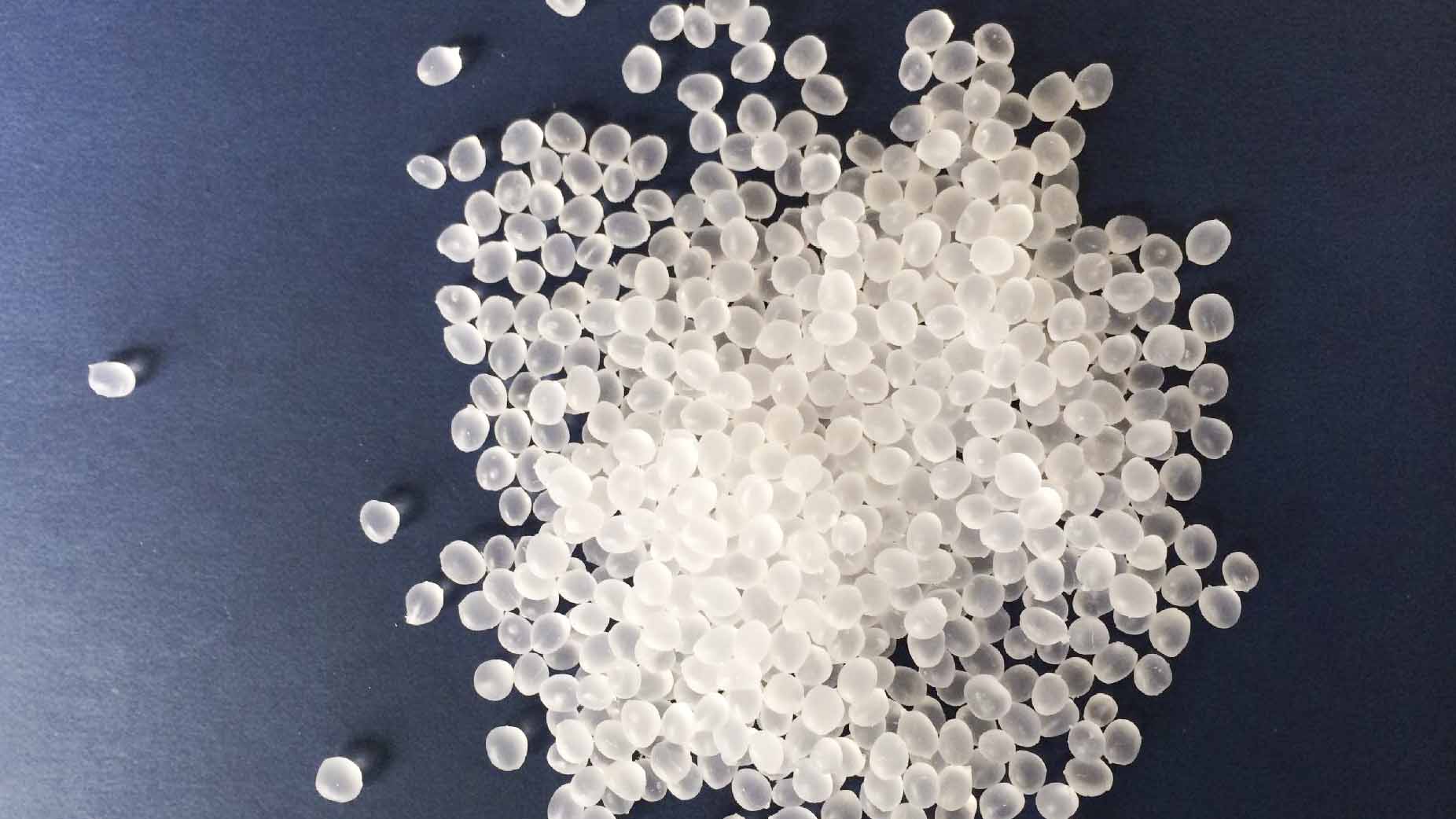

TPE material is a kind of TPE material with superior processing performance, no vulcanization, recyclability and low cost. It can be used not only for secondary injection molding, but also for composite molding with hard plastics such as PP, PC, ABS and PA, or directly with a single material. So what are the injection molding process parameters of TPE?Mastars provides rapid CNC machining,rapid prototyping services,custom metal stamping. It has industrial grade large-scale 3D printing equipment and CNC equipment, covering a variety of printing processes in automobile manufacturing, mold manufacturing, medical treatment, and other fields

1、 Selection of TPE material for injection molding machine

Vertical injection molding machine: the vertical injection molding machine only needs to complete the insert, which is convenient for molding and operation, and is conducive to precision molding in manufacturing. This feature is very important, but also an important factor in consumer choice.

Horizontal injection molding machine: most of the injection molding machines on the market use horizontal injection molding machines. Due to the low contrast of the body, there is no requirement for the clearance of the delivery room, that is to say, its material supply will be more convenient, and it can also be repaired well in case of problems. If there are multiple products, the transportation of formed products is relatively simple, and the subsequent packaging is also relatively simple. The results show that the performance of TPE plastics in injection molding machine has been improved to a certain extent.

2、 TPE injection molding process parameters

Thermoplastic elastomer (TPE) material injection molding technology processes raw materials and then synthesizes polymers. Injection molded rubber products have the following advantages: they can be vulcanized by rubber injection molding machine, and the vulcanization time is shortened from 20 minutes to less than 1 minute; It can be vulcanized by extruder, with fast vulcanization speed and short vulcanization time; Waste products (depilation, extrusion waste rubber) and final waste products can be directly recycled, with large self reinforcement, greatly simplified formula, greatly reduced influence of complexing agent on polymer, and easier to master mass function.

3、 Precautions for injection molding of TPE materials

1. In the process of TPE injection molding, the process and appearance of materials need to be checked before TPE molding. It is necessary to dry the material and determine its moisture content. At high temperature, the moisture content of TPE material should be less than 5%, or even 2% - 3%, so it is usually dried in a vacuum drying oven at 75 ℃ - 90 ℃ for 2 hours.

2. The drilling materials shall be well sealed to avoid the loss of drilling effect caused by secondary moisture. The bearing capacity of the drilling funnel is generally 2.5 times of the hourly material consumption of the injection molding machine.

3. TPE materials based on SBC are superior to other TPE materials in color. Therefore, only a small amount of color masterbatch can achieve a certain color development effect, and the color produced is purer than other TPEs. Generally speaking, the viscosity of Color Masterbatch should be lower than that of TPE, because the melt index of TPE is higher than that of Color Masterbatch, which is conducive to the dispersion process of color masterbatch and make the dispersion of Color Masterbatch more uniform.

In the injection molding process of thermoplastic elastomer (TPE), the quality and performance of products are determined by setting appropriate temperature. The reactor should be constructed at a lower temperature where the material enters. When using color masterbatch, in order to improve the mixing conditions, the temperature of transition zone should be set above the melting point of color masterbatch. The temperature of the area closest to the nozzle should be set close to the desired melt temperature. The mold temperature should be higher than the condensation temperature in the injection area. Higher mold temperature can improve the appearance of welds and products.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.