Background

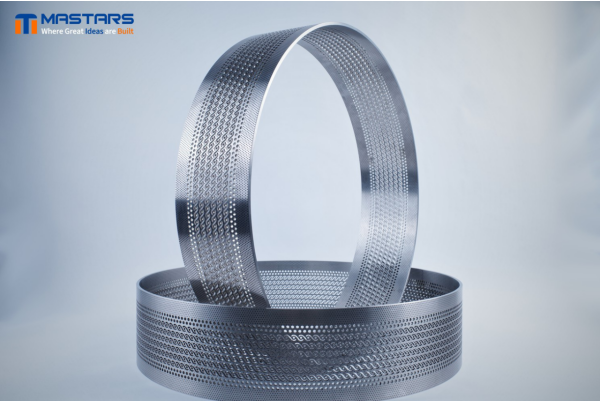

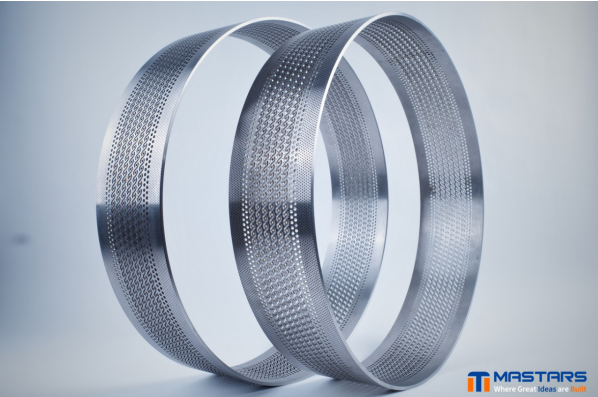

As the textile industry advances toward higher efficiency and precision, Mastars leverages multiple advanced processes—laser engraving/marking, welding, and precision finishing—to build key ring-shaped components that inject fresh momentum into textile manufacturing.

The challenge

Conventional textile machine components face limits in precision and durability. Some production steps still rely on chemical treatments that run counter to green-manufacturing trends.

Mastars solution

Mastars integrates laser engraving/marking, welding, and precision grinding/polishing to craft ring-shaped core components for textile applications. Laser engraving renders complex, fine functional textures or identifiers on the surface; advanced welding ensures structural integrity. Standard materials include 304/316L stainless steel, with optional nickel-based alloys for acidic media to enhance corrosion resistance in textile environments. Professional finishing yields smooth, burr-free surfaces and maintains uniform clearance with rotating parts to boost running stability.

System features

· Material: Wear-resistant 304/316L stainless steel

· Thickness: 0.1 mm – 0.3 mm

· Surface: Fine finishing, burr-free

· Quality Assurance: 100% AOI; flow/pressure-drop testing; weld burst/torque testing; full batch traceability

Benefits

Multi-process synergy: High precision and durability help textile machinery run efficiently and cut unplanned downtime.

Green manufacturing: Production is environmentally friendly and aligned with sustainability goals.

Stable geometry: Controlled roundness and reliable welds preserve uniform clearance with mating rotating parts for smooth throughput.

Medical-grade stainless & deburring: Mastars employs medical-grade stainless steel and meticulous finishing to ensure burr-free surfaces.

Corrosion resistance & running stability: Materials and processes support long-term, stable operation.

Easy to clean: Electropolished surfaces reduce residue adhesion and shorten cleaning cycles.

Use cases

· Textile industry: Core transmission/support components and printing modules across various textile machines

· Automotive manufacturing: Bearing outer rings, sealing rings, and other critical components in powertrain and driveline systems

· Medical devices: Transmission/support ring components in devices such as infusion pumps and certain surgical instruments

· Electronics: Gear rings or locating rings in precision instruments and electronic equipment, fitting compact internal layouts

If you have a brilliant idea, Mastars can provide you with excellent assistance. To ensure your ideas don't go to waste,contact us today. Where great ideas are built.

Hot Cases

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.