Driven by the "dual-carbon" strategy, the new energy vehicle industry has witnessed explosive growth, with battery system safety, lightweight performance, and reliability becoming core competitiveness for automakers. As a key supplier of aluminum extrusions and precision machining solutions for automotive components, Mastars has long focused on the R&D and manufacturing of EV battery tray materials and supporting CNC machining services. The battery tray, known as the "safety armor" and "bearing foundation" of the battery pack, relies heavily on high-quality aluminum profiles and precise CNC processing to meet strict operational requirements. Mastars integrates its advantages in aluminum extrusion materials and customized CNC machining, providing one-stop solutions for global automakers, and laying a solid foundation for the safe and efficient travel of electric vehicles.

I. Core Demands of Battery Trays and Mastars' Material & Processing Positioning

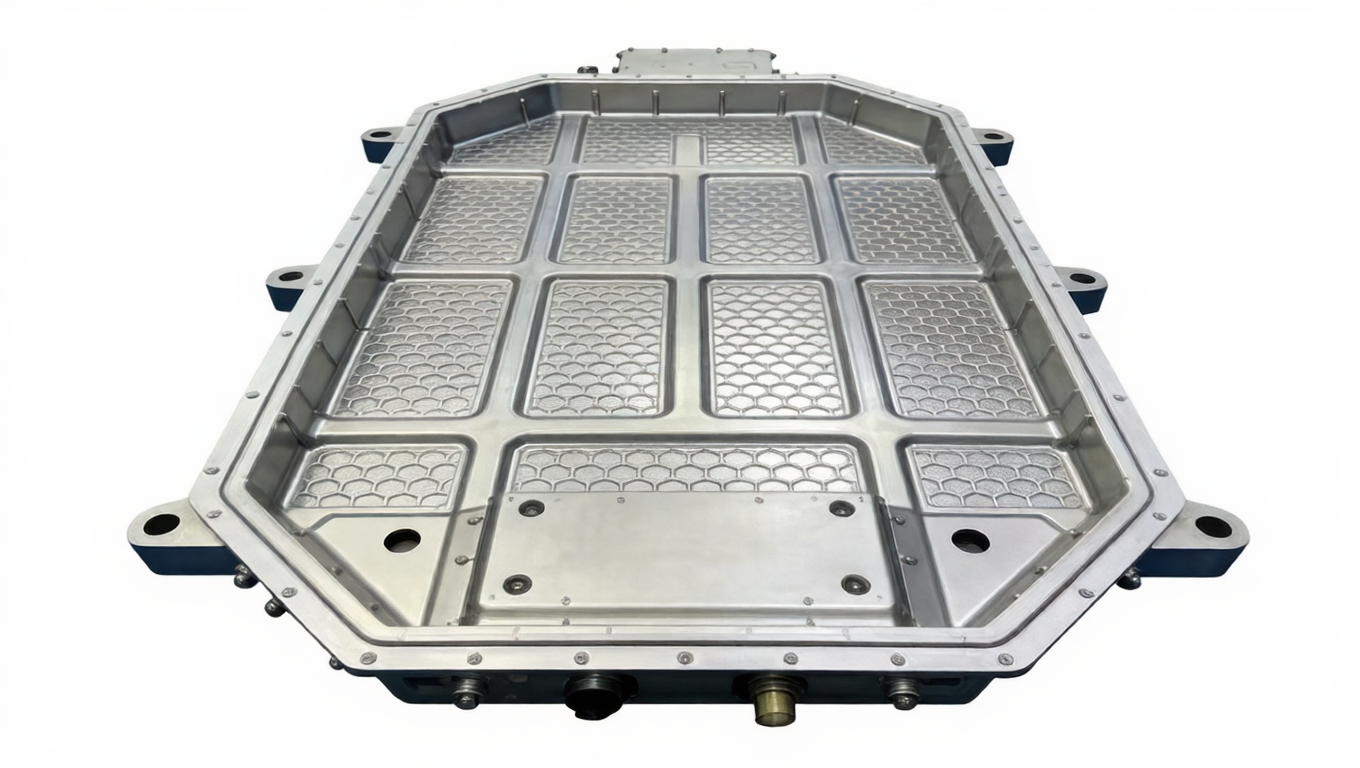

The battery tray is a critical structural component connecting battery modules and the vehicle body, and its manufacturing quality directly affects the driving safety and cruising range of EVs. Mastars has targeted the core needs of battery tray manufacturing and launched a series of aluminum extrusion products and matching CNC machining services. Currently, Mastars mainly supplies aluminum alloys such as 6061-T6, 6063-T5, 6082, and 5083 for battery trays, which feature lightweight properties (density only 2.7g/cm³), high strength (tensile strength ≥240MPa), excellent welding performance, and good thermal conductivity—effectively reducing vehicle weight, improving battery heat dissipation efficiency, and extending cruising range.

However, the processing characteristics of these aluminum alloys and the complex structural requirements of battery trays pose severe challenges to manufacturing, which Mastars has addressed through professional CNC machining capabilities:

• Extremely high dimensional accuracy requirements: Battery trays for pure electric passenger vehicles (such as Tesla Model 3 and BYD Han) and commercial vehicles have different size specifications, but all require mounting surface flatness ≤0.1mm and hole system positional accuracy ±0.05mm. Mastars achieves precise control of these tolerances through advanced CNC machining processes to avoid battery module installation deviations.

• Complex structure and easy deformation: Most battery trays adopt thin-walled cavity structures integrated with heat dissipation channels and mounting interfaces. Mastars optimizes CNC cutting parameters and process paths to minimize warping and deformation caused by cutting forces, ensuring structural stability of the trays.

• Strict surface quality and reliability requirements: The tray surface must be free of cracks, scratches, and pores, and pass 1000-hour salt spray tests and helium leak tests (leak rate ≤1×10⁻⁶ mbar·L/s). Mastars combines CNC machining with anodizing, powder coating, and electrophoretic coating technologies to enhance corrosion resistance and surface quality of the trays.

Traditional processing technologies struggle to balance these requirements, while Mastars' integrated solution of "aluminum extrusion + customized CNC machining" has become a core support for high-quality battery tray manufacturing.

II. Core Applications of Mastars' CNC Machining in Battery Tray Manufacturing

Mastars focuses on the two mainstream manufacturing routes of battery trays (extruded aluminum welded type and integral die-cast type) and has formed targeted CNC machining solutions that cover the entire process from aluminum profile blank processing to finished product delivery. These solutions are closely integrated with its aluminum extrusion business to provide customers with one-stop services.

(I) Process Adaptation: Tailored Solutions for Two Manufacturing Routes

The extruded aluminum welded tray is the mainstream process in the market, and Mastars has formed a complete processing chain integrating "aluminum profile supply + component CNC machining + assembly welding supporting". First, Mastars provides customized aluminum extrusions according to customer needs, and obtains blanks through precision cutting. Then, using high-speed CNC machining centers, it completes milling, drilling, tapping and other precision processing of frames, crossbeams and other components to ensure that the dimensional tolerances of each component meet welding requirements. After the customer completes the welding forming, Mastars can also provide overall precision machining services to correct welding deformation and ensure the flatness and assembly accuracy of the mounting surface. For large-size battery trays of pure electric commercial vehicles, Mastars adopts large-stroke gantry CNC machining centers, which feature high-speed electric spindles (up to 15000rpm) and full-stroke rigid support, ensuring efficient and precise processing of large workpieces.

For integral die-cast trays, which are increasingly popular in the market, Mastars has optimized its CNC machining capabilities to match the complex structural characteristics of die-cast parts. It uses high-precision five-axis machining centers to complete the one-time processing of special-shaped cavities, complex flow channels and multi-surface mounting holes of die-cast trays, avoiding errors caused by multiple clamping. This not only improves processing efficiency but also ensures the consistency of product quality, which is well-matched with Mastars' high-strength aluminum profiles for die-cast supporting.

(II) Key Technologies: Overcoming Processing Difficulties with Professional Advantages

Based on the characteristics of its self-supplied aluminum alloys (such as good ductility and easy deformation), Mastars has optimized CNC machining technologies to solve key industry pain points. In terms of tool selection, Mastars uses diamond-coated tools to improve cutting edge sharpness and reduce material extrusion deformation, which is particularly suitable for the processing of 6061 and 6063 aluminum alloys. In terms of parameter setting, it adopts high-speed and low-feed cutting parameters (spindle speed up to 12000-15000rpm) and matches the through-spindle coolant system (pressure 30-70bar) to effectively reduce cutting temperature and stress accumulation, avoiding workpiece deformation. At the same time, Mastars integrates MES production management system to real-time monitor processing data, correct processing errors dynamically, and ensure the consistency of mass production.

In terms of surface quality control, Mastars forms a synergistic advantage between CNC machining and subsequent surface treatment processes. It optimizes the cutting path to reduce surface scratches, and uses high-pressure spray and air blowing cleaning systems to remove iron chips and oil stains after processing, laying a good foundation for subsequent anodizing and powder coating. Through this integrated process, Mastars' battery tray products have achieved stable film thickness (80±5μm), grade 0 adhesion (cross-cut test), and successfully passed 1000-hour salt spray tests, fully meeting the reliability requirements of automakers.

(III) Equipment Configuration: Matching Diversified Customer Needs

Mastars has configured a complete set of CNC machining equipment according to the diversified needs of different customers and battery tray products. For small and medium-sized battery trays of passenger vehicles (such as Tesla Model 3 and BYD Han), it uses vertical CNC machining centers with high flexibility and fast switching capabilities to meet the needs of multi-variety and small-batch production. For large-size battery trays of commercial vehicles (electric buses, electric trucks), it is equipped with large-stroke high-speed gantry machining centers, which are equipped with double spiral chip conveyors and full-shield guards to ensure efficient and continuous processing. For complex integral die-cast trays, high-precision five-axis machining centers are used to achieve multi-dimensional linkage processing, improving the processing efficiency of complex features. In addition, all machining equipment is equipped with contact tool setters and workpiece measurement systems to further improve processing stability and traceability.

III. Application Cases: Mastars Empowers Automakers with High-Quality Solutions

In practical industrial applications, Mastars' "aluminum extrusion + CNC machining" integrated solution has been widely recognized by global automakers, helping customers achieve efficient mass production of battery trays while ensuring product quality.

For example, Mastars has provided customized aluminum profile and CNC machining supporting services for a well-known international automaker (supplying Tesla Model 3 battery trays). By optimizing the aluminum alloy formula and CNC processing parameters, Mastars shortened the customer's battery tray production cycle from 30 days to 7 days, and the single-line annual production capacity exceeded 100,000 sets. At the same time, the product pass rate reached 99.2%, and the salt spray test life exceeded 1000 hours, fully meeting the strict requirements of the automaker for battery tray safety and reliability.

In response to the urgent demand for battery trays from a domestic new energy commercial vehicle enterprise, Mastars quickly adjusted its production plan, relying on its self-owned aluminum profile production line and flexible CNC machining capacity. It completed the development and delivery of 500 sets of large-size battery trays in 5 days (3 days ahead of the original plan), solving the customer's production schedule pressure. This case fully reflects Mastars' advantages in rapid response, flexible production and reliable quality control.

IV. Future Trends: Mastars' Layout in Intelligent and Green Manufacturing

With the upgrading of the EV industry towards lightweight, intelligence and greenization, battery trays are developing in the direction of integration, high precision and multi-function. Mastars will further integrate its business advantages and promote the innovation and upgrading of CNC machining technology in battery tray manufacturing.

In terms of intelligence, Mastars plans to build virtual processing scenarios through digital twin technology, realize simulation optimization and real-time monitoring of the entire process from aluminum profile production to CNC machining, and improve production efficiency and quality control level. In terms of process integration, it will deepen the coordination between CNC machining and aluminum extrusion, laser welding, surface treatment and other processes, and provide customers with more comprehensive one-stop solutions. In terms of greenization, Mastars will promote the application of water-based cutting fluids and energy-saving CNC equipment, reduce the environmental impact of the processing process, and respond to the global "dual-carbon" strategy.

At the same time, with the increasing integration of battery tray functions (such as integrated liquid cooling systems and sensor mounting interfaces), Mastars will further improve the precision of CNC machining (towards micrometer level) and the processing capacity of complex features, and expand the application of five-axis linkage and high-speed cutting technologies. It will also continue to optimize aluminum alloy materials, develop higher-strength and more corrosion-resistant alloys, and provide strong support for the upgrading of EV battery systems.

Conclusion

As a professional supplier of EV battery tray aluminum profiles and precision machining solutions, Mastars has established a core competitive advantage in the industry by integrating aluminum extrusion and CNC machining businesses. The manufacturing precision of battery trays directly determines the safety and cruising range of EVs, and Mastars has effectively met the strict requirements of automakers through its advanced CNC machining technology, optimized process solutions and reliable product quality.

From material R&D to process optimization, from equipment upgrading to intelligent manufacturing, Mastars has been committed to providing high-quality, efficient and customized solutions for global new energy vehicle enterprises. In the future, with the in-depth development of the EV industry, Mastars will continue to deepen technological innovation, expand business layout, and play a more critical role in the field of battery tray manufacturing, contributing to the accelerated development of the global green travel era.

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.