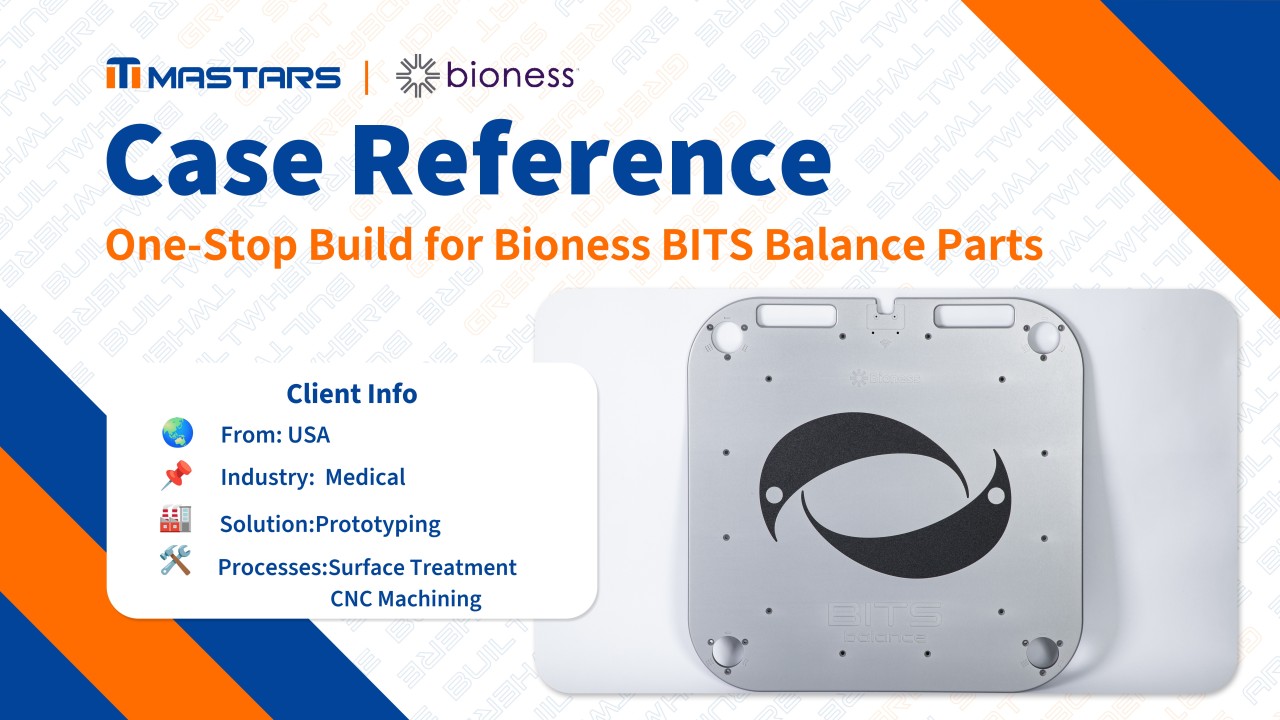

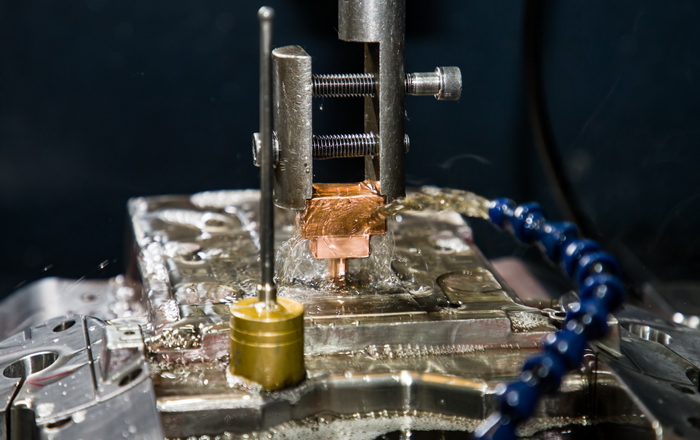

The equipment of hardware machining manufacturers, whether it is lathes, milling machines or grinders, is inseparable from cutting fluids. Mastars uses CNC technology to make prototypings and mass production, providing customers with rapid prototyping services and high-precision parts production. CNC should be more and more widely used in today's industrial manufacturing services.

Cutting fluids can be divided into oil-based and water-based. It needs to be selected according to different equipment. For grinding machines, lathes, milling machines, and wire cutting, water-based cutting fluids should be selected, and oil-based cutting fluids should be selected for electrical discharge machining.

The cutting fluid should have good cooling, lubricating, anti-rust, degreasing cleaning, anti-corrosion functions, and easy to dilute and so on.

The first function is lubrication: the lubricating effect of metal cutting fluid in the cutting process can reduce the friction between the rake face of the tool and the chip, the flank face and the machined surface of the precision machined part, and form part of the lubricating film, so as to reduce cutting force, friction and power consumption, reduce the surface temperature and tool wear of the friction part between the tool and the workpiece blank, and improve the cutting performance of the workpiece material.

The second function is cooling: the cooling effect of the cutting fluid is to take the cutting heat away from the tool and the workpiece through the convection and vaporization between it and the tool (or grinding wheel), chip and workpiece, so it effectively reduce the cutting temperature, reduce the thermal deformation of workpiece and tool, maintain the hardness of the tool, and improve the machining precision and tool durability of precision mechanical parts.

The third function is cleaning: in the process of metal cutting, the cutting fluid is required to have a good cleaning effect, remove the generated chips, grinding chips, iron powder, oil stains and sand particles, prevent the contamination of the machine tool, the workpiece and the tool, so as to keep the cutting edge of the tool or grinding wheel sharp, so that it does not affect the cutting effect.

The fourth function is rust prevention: in the process of metal cutting, the workpiece is corroded by contact with the environmental medium and the corrosive medium such as sludge generated by the decomposition or oxidation of the cutting fluid, and the surface of the machine tool parts in contact with the cutting fluid will also be corroded. Therefore, the cutting fluid must have the function of anti-rust.

Mastars

With more than 20 years of industry experience and strong technical level, Mastars provides the most reliable industrial manufacturing services to more than 800 well-known companies around the world. If your rapid prototypings or functional parts need CNC machining, please contact Mastars, we will develop the best solution for you, provide you with products that exceed your expectations and one-stop service.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Hot Articles

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.