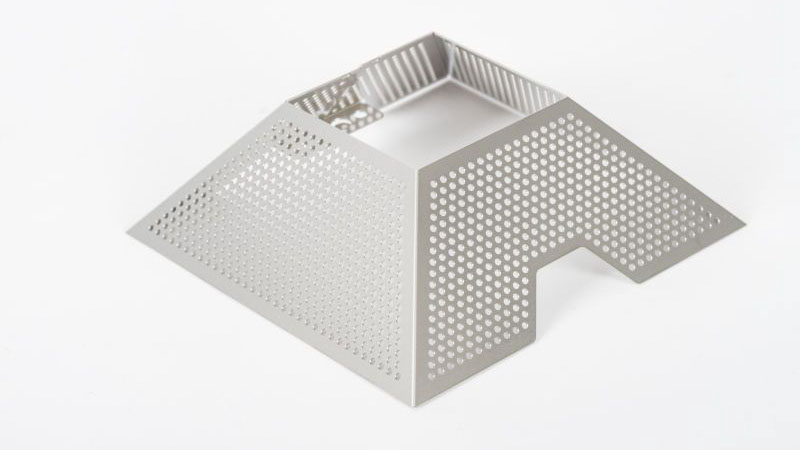

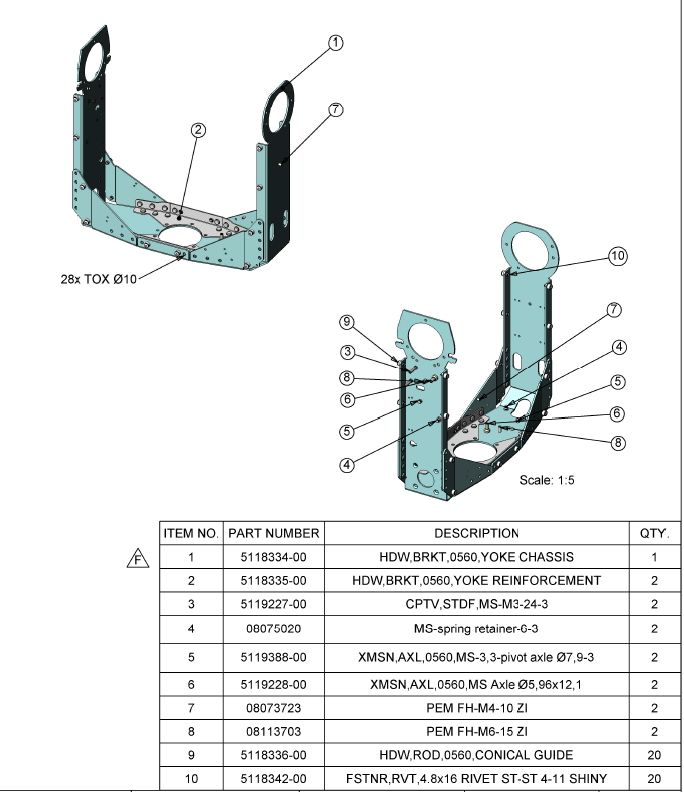

Yoke chassis is the key part of lighting movement/rotation. Through structural innovation, the new model is designed as a single die-casting component with complex modeling structure to replace more than 60 parts. Traditionally the yoke chassis usually go through the technological process of stamping, welding and final assembly around 60 parts together. In addition, the traditional stamping process produces a large amount of waste residue. The integrated die casting can also improve the endurance of the lighting by reducing weight, increase the acting area of the anti-collision beam, improve the rigidity of the lighting. Without the splicing of too many stamping parts, the quality consistency of movement/rotation components is also guaranteed.

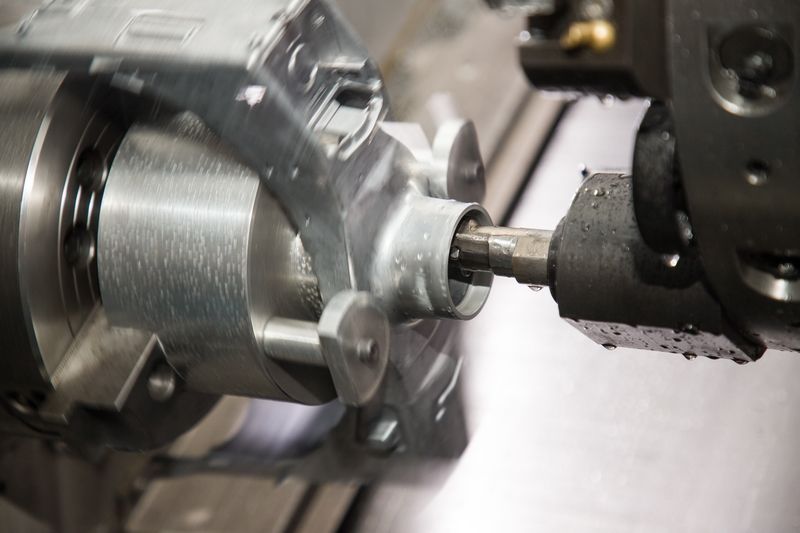

but for die

casting processing, it’s big challenge for tooling, raw material and post CNC

Hot Cases

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.