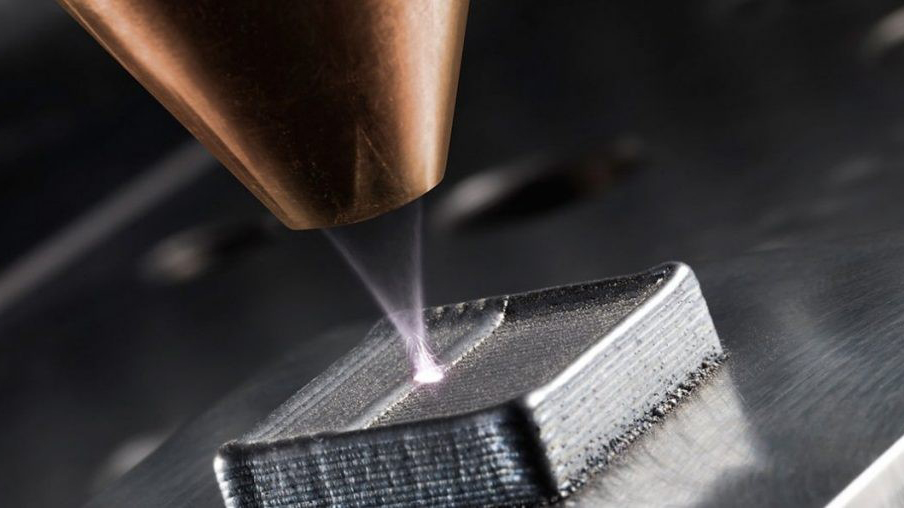

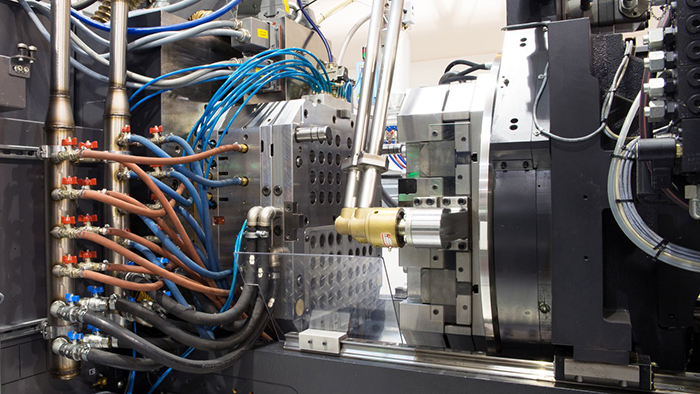

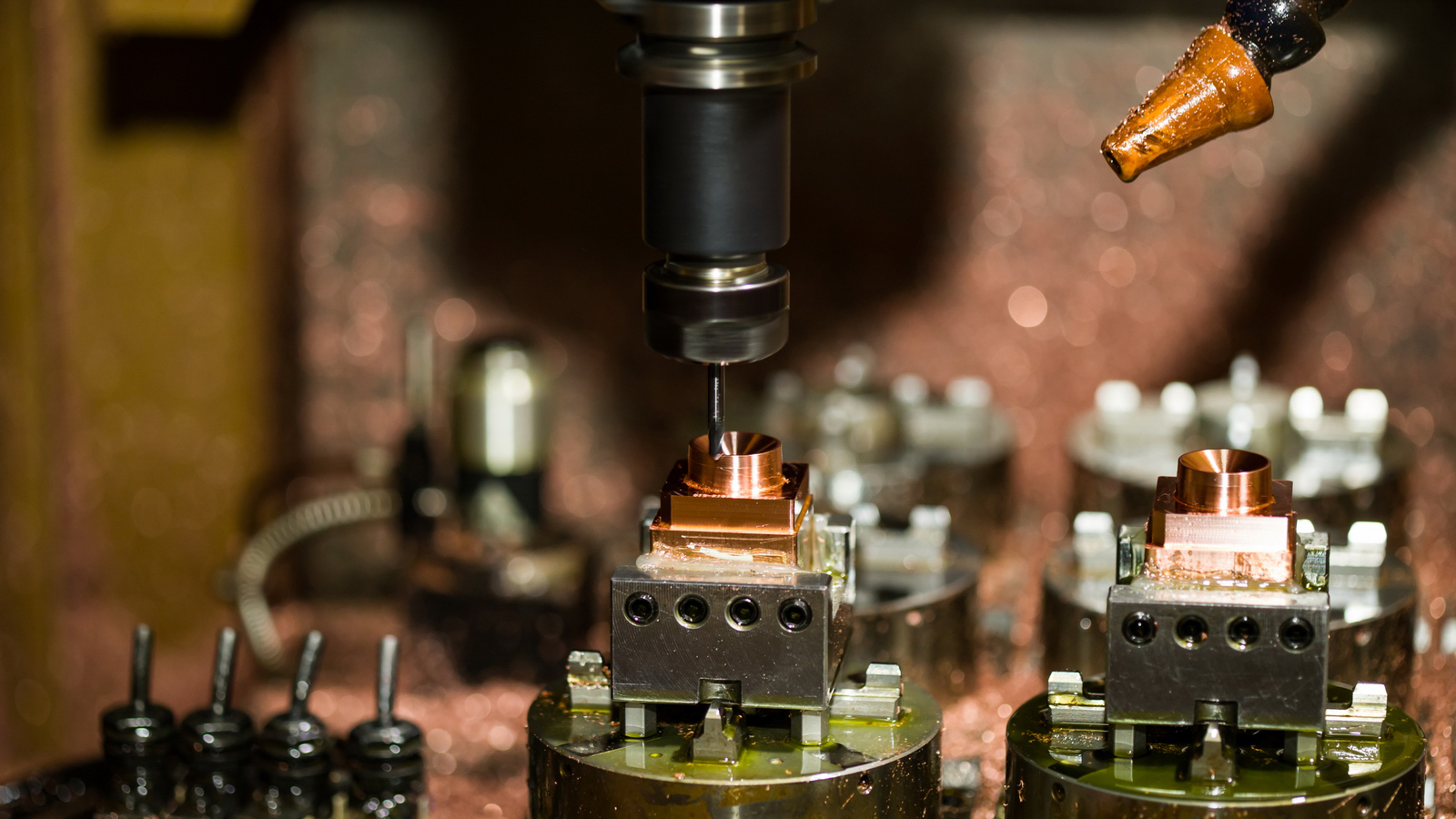

Are you wondering why verify product design or validate product design?Here are reasons why this testing is important in any product development.Mastars' rapid prototyping service can provide various prototyping services including 3D printing, CNC machining and vacuum casting, according to customers' needs, verify you're designed, provide fast, efficient, and cost-effective services, and lay the foundation for future mass production of your products.

Testing also offers an opportunity to the developing team to document their tangible results. By documenting the results of each stage of the testing process, the team members get a chance to share information on the progress of the design process. This way, they know precisely what has been achieved during the product development process.

Preparation in product validation includes gathering all necessary data related to the product. It also requires conducting research studies to determine if other organizations have already developed any existing standards.

After collecting all relevant data, it is now time to validate the product. During this step, the developers validate the product against its requirements. This means that the researcher checks if the product meets the expected functionalities. They make sure that the product works appropriately under various conditions. In addition, they verify how well the product complies with the standard operating procedures.

Once the validation phase is complete, the developer analyzes the collected data. They look at the findings and determine why some parts of the product failed while others performed successfully. The analysis will provide valuable insight into areas of improvement.

Based on the analysis conducted during the previous step, the researchers may change certain aspects of the product. For example, suppose the product was found to work fine but did not comply with the standard operating procedure. In that case, the researchers might suggest changing the product’s functionality to meet the requirement.

To ensure that the new version of the product still satisfies the customer’s expectation, a final round of testing must be done. During this step, researchers check if the newly created product functions correctly. They do this by running different scenarios through the system. If everything goes smoothly, then the product is ready for release.

After completing the entire verification process, the designer prepares a detailed report about the product. In this report, they describe the overall performance of the product. It provides details regarding the product’s features, functionality, and usability.

Validation of work products involves documentation of the processes used to create the product.These documents include specifications,design drawings,prototypes,test plans,etc. These materials can help the developer improve his skills and gain more knowledge about the product he is working on.

Verification and validation are very important steps in the product development and design process. Both these activities involve analyzing the product from multiple perspectives. By doing so, we can identify potential problems before releasing them to the market. We can also learn what needs to be improved upon. As we mentioned earlier, verifying the product helps us understand whether the product has met our expectations. On the other hand, validating the product ensures that the product performs according to the required standards. Therefore, both verification and validation play an essential role in ensuring that the product is fit for use.

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China

Contents:

rapid prototyping service