Mastars offers top-of-the-line Aluminum extrusion services, including piercing, bending, welding, and notching. Our experts can also help with standard, custom shapes, and designs. Currently, we provide aluminum fabricated components and extruded aluminum products to various businesses and industries.

In addition, depending on the alloy type, aluminum alloys can be up to 2.5 times lighter than their steel counterpart. These properties make aluminum hard alloy extrusions the most attractive choice for aerospace, commercial, and military applications.

-

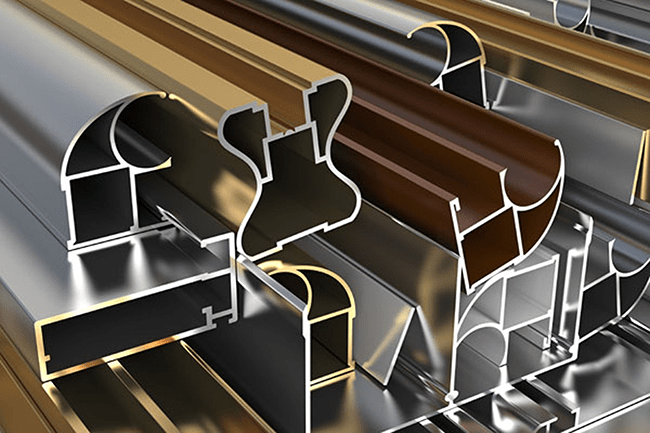

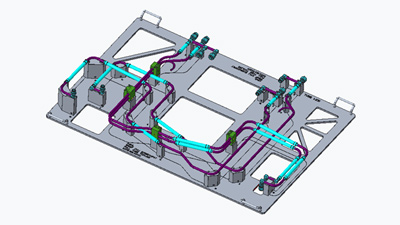

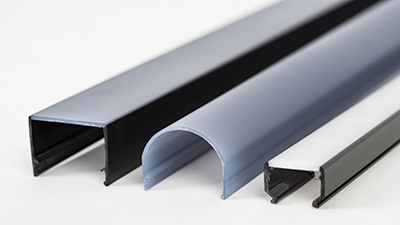

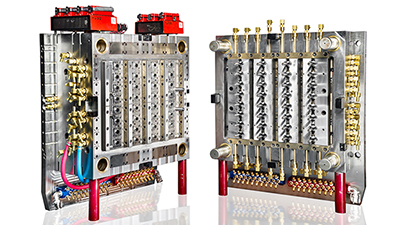

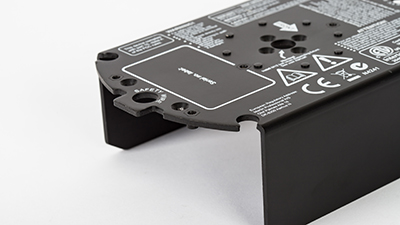

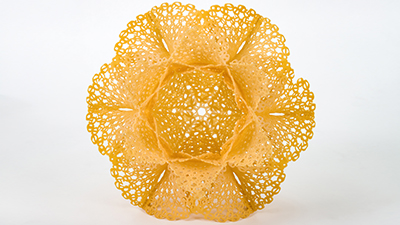

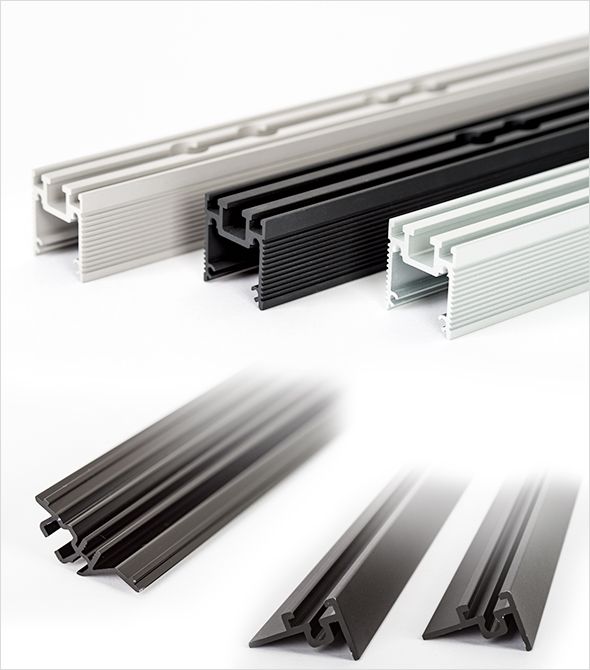

Our aluminum extrusion capabilities We extrude 6000-series aluminum alloy to produce standard and custom profiles to meet the exact needs of our customers. Our wide range of aluminum extrusion capabilities allows us to serve a diverse OEM customer base. >6000-series aluminum alloys >Standard and custom profiles >Multiple direct extrusion presses >Closed loop extrusion speed controls >Weight-per-foot range of 0.033 to 8 lbs & Circle size up to 8 inches >Extrusion recipe system setting

Our aluminum extrusion capabilities We extrude 6000-series aluminum alloy to produce standard and custom profiles to meet the exact needs of our customers. Our wide range of aluminum extrusion capabilities allows us to serve a diverse OEM customer base. >6000-series aluminum alloys >Standard and custom profiles >Multiple direct extrusion presses >Closed loop extrusion speed controls >Weight-per-foot range of 0.033 to 8 lbs & Circle size up to 8 inches >Extrusion recipe system setting

Mastars factory is able to run 7 days a week to further shorten delivery times

Mastars is to deliver the complete extrusion solution for your business. Whatever processes you need, from fabrication to finishing, we’ve got you covered. And once your component’s complete, we’ll arrange the delivery or a custom stock holding arrangement – whatever suits you best.

What’s more, we can work with you on an ongoing basis to come up with innovative, time-saving, and cost-effective solutions that will keep your business a step ahead of the competition.

-

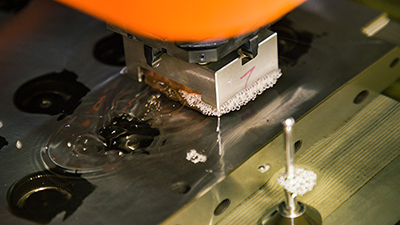

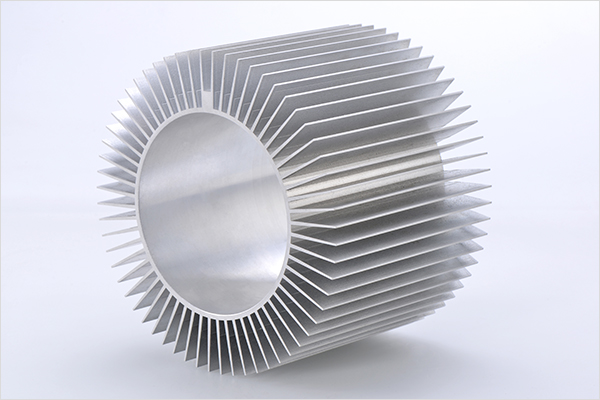

- In addition to the advantages of extrusion process, aluminum,as one of the most commonly used extruded metal materials, has its unique physical and chemical properties. Durable. Aluminum corrosion resistance, corrosion resistance and weather resistance is one of its most significant advantages. Light and strong. Aluminum is more than 33% lighter than steel and retains most of its strength. Good thermal conductivity. Aluminum is an excellent heat conductor. The contour design of aluminum extrusion can maximize the heat conduction surface area and form a heat channel. Fashionable appearance. Extruded aluminum can be painted, electroplated, polished, and anodized, providing engineers with a wider range of appearance options than other materials. Wide application range. Basically, any section shape can be formed by aluminum extrusion, and different sections can be designed to meet the requirements of different application environments. Easy secondary processing.Aluminum extrusions can be easily formed, cut, drilled, processed, stamped, bent and welded to meet specific needs. The die of aluminum extrusion is simple, the processing cycle is short and the cost is low. Absorb impact and deformation.Aluminum extrusions maintain strength and flexibility under load and rebound from impact. Environment protection.Aluminum is an environmentally friendly material and easy to recycle.