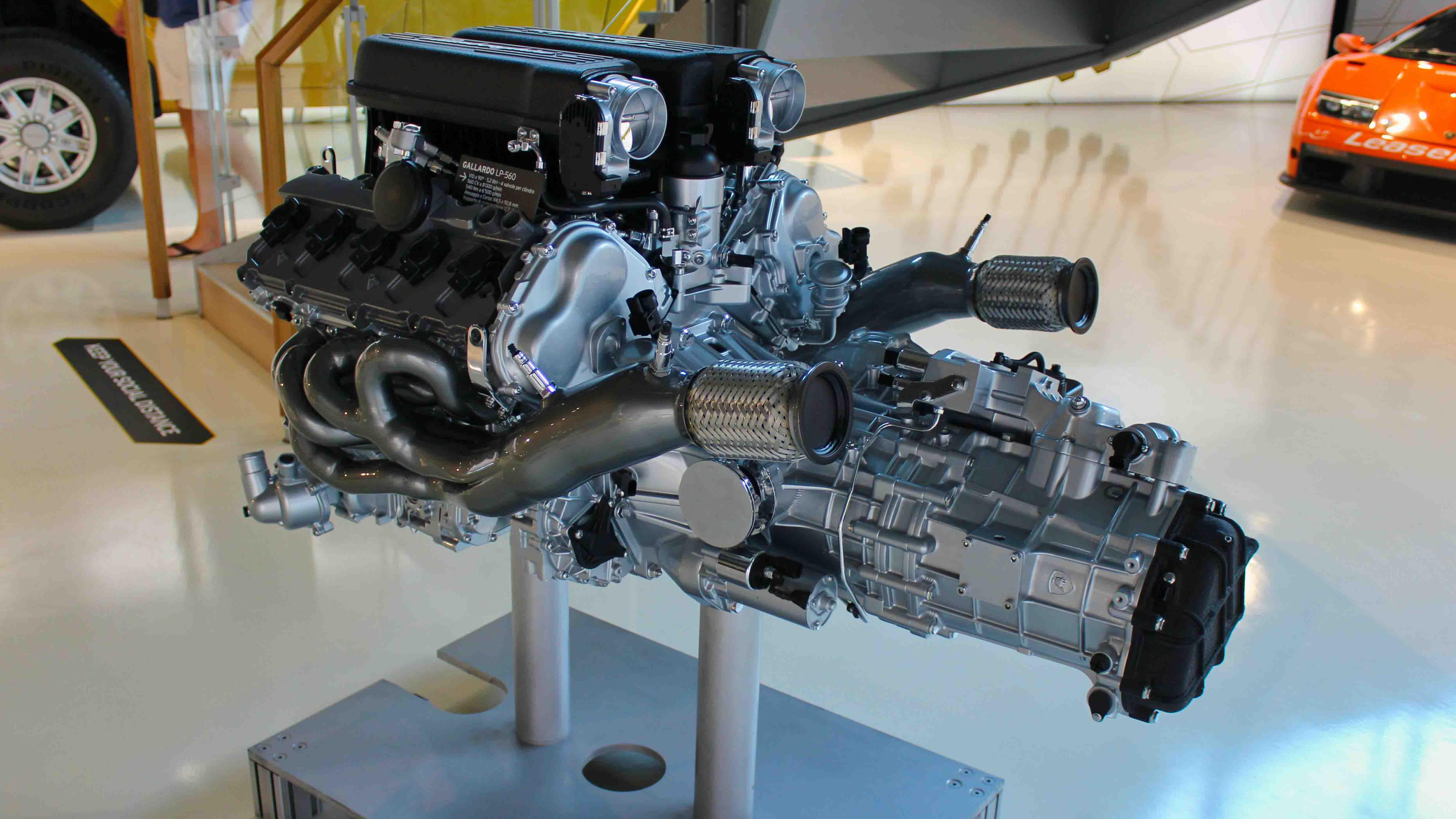

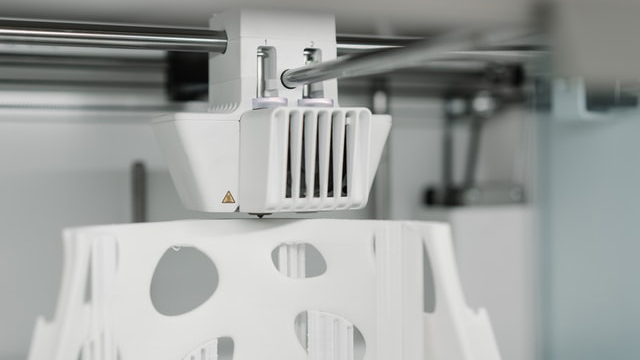

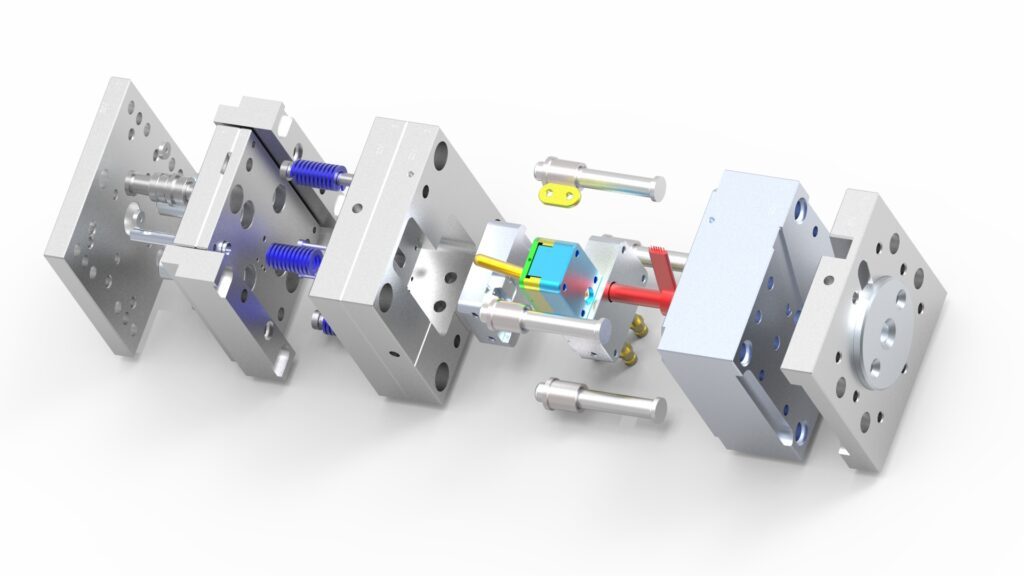

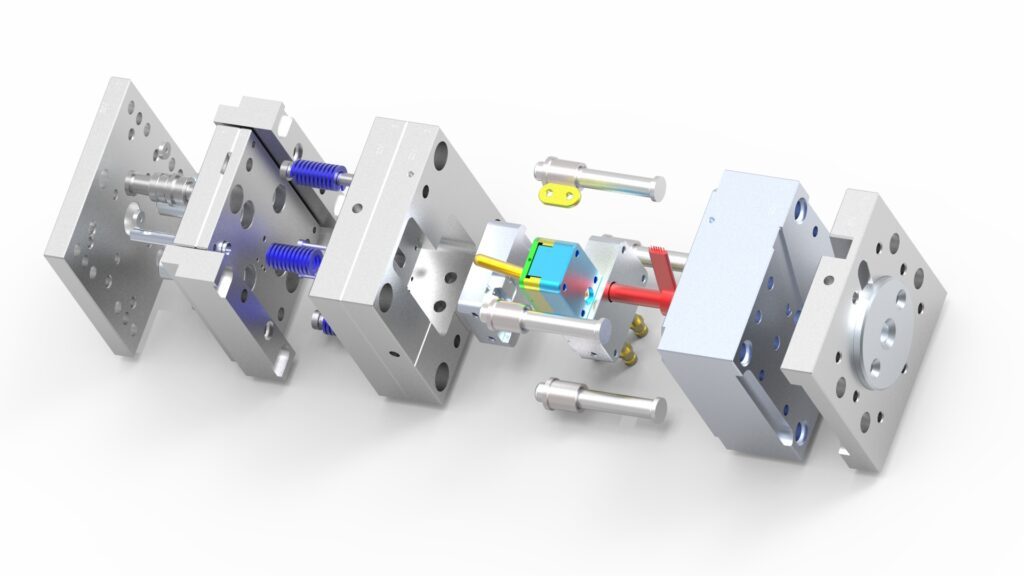

As a modern manufacturer of precision mechanical parts, mastars takes CNC machining as the core process, has physical factories and testing equipment, and integrates supporting manufacturing resources such as rapid prototyping, mold and post-treatment to provide customers with rapid proofing, small and medium-sized batch production, manufacturing and trial assembly, so as to truly achieve a one-stop service that saves worry and effort.

1. Rough and finish machining are carried out separately. In order to reduce the influence of cutting force and cutting heat, the deformation of sleeve parts produced by rough NC lathe can be corrected in finish machining.

2. Reduce the influence of clamping force and take measures to reduce the influence of clamping force in process

(1) When radial clamping is used in precision

CNC machining, the clamping force should not be concentrated on a certain radial section, but should be distributed over a large area to reduce the clamping force borne by the workpiece per unit area; How to install the workpiece in an open ring with appropriate thickness and clamp it together with the ring, or use a special claw to increase the contact area; When positioning with holes, open mandrel should be used for clamping;

(2) The position of clamping force should be selected at the part with strong rigidity, so as to improve the deformation of thin-walled parts under the action of clamping force;

(3) Change the direction of clamping force and change radial clamping to axial clamping.

(4) In precision CNC machining, a process boss or process thread with enhanced rigidity is made on the workpiece to reduce clamping deformation. During machining, it is clamped with a claw with special structure, and the convex edge is cut off at the end of machining.

Reduce the influence of cutting force on deformation

1. Increase the main deflection angle and main wall angle of the tool to make the blade sharp and reduce the radial cutting force;

2. Separate rough machining from finish machining, so that the deformation of sleeve parts produced by rough machining can be corrected in finish machining, and adopt small cutting parameters;

3. The inner and outer circular surfaces are processed at the same time to offset the cutting force;

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China