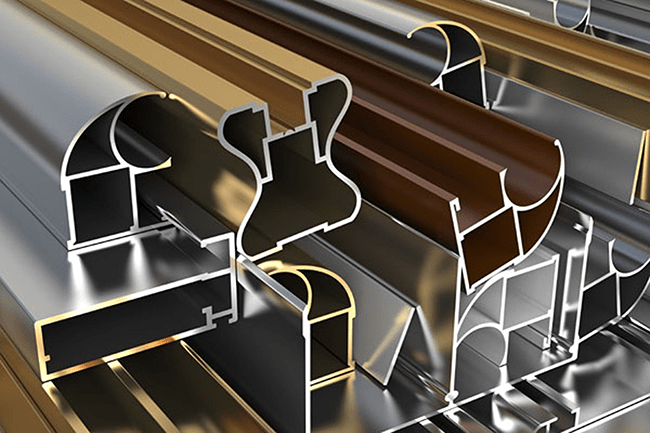

Stainless steel forgings can be divided into different types. The most common ones are free forging and die forging.

Mastars' rapid prototyping service can provide various forging services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products.

The former mainly uses the impact force generated by man-made machines, or greater pressure, to change the shape of stainless steel metal materials between the two anvil blocks, so that the required parts can be obtained. Of course, it can also be divided into the utilization of man-made machines and the utilization of labor according to the specifications and requirements of different enterprises. The latter is mainly through the open and closed forging methods to make some stainless steel materials squeeze greatly in a certain die, and then change their shape.

Mechanical parts are usually exposed to corrosive media such as atmosphere, steam and water, so the selection of stainless steel forgings can effectively resist the corrosion of air, water, acid, alkali salt or other media. After forging method, due to the deformation and recrystallization of stainless steel, the original coarse dendrite and columnar grain are fine, and the uniform axial recrystallization structure makes the ingot original racial segregation, porosity, porosity, slag compaction and welding, such as the metal with tighter microstructure, plasticity and mechanical properties. Ensure that the parts have good mechanical properties and long service life. The production of precision die forging, extrusion temperature and other forgings is unparalleled. The pressure of stainless steel forgings refers to the required shape or appropriate compressive force of stainless steel material through plastic deformatio

Mastars is a prototype company in China. We employ proven prototype technologies(rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China