Mastars provides 3D printing technology, Focusing on Aerospace, Automotive, Manufacturing, Consumer Goods, Healthcare, Research, and other industries, the company provides comprehensive AM solutions from functional test prototyping, tooling, and fixture manufacturing to direct mass production of final products, covering equipment, software, high-performance materials, and printing services.

With the application advantages of 3D printing technology in the mold field becoming more and more obvious, more and more enterprise manufacturers began to try to use this technology to complete production tasks, but the results were different. Some enterprises doubled their profits after applying 3D printing technology, while others had problems, and then began to accuse "mold 3D printing is just a gimmick!", And Xiaobian just wants to ask: are you really using the mold 3D printing right?

At this stage, 3D printing technology is generally used in the cooling water system, which can shorten the cooling cycle and improve the production efficiency of injection molding products.

So can all molds play this role? The answer is yes. Do all molds need to be used? The answer is naturally No. For example, in the recent "helmet mold explosion", the sales volume has increased greatly, and many factories can't keep up with the production. Therefore, we asked whether we can carry out 3D printing to shorten the cooling cycle and improve efficiency, but we didn't recommend them. Why?

Therefore, how to choose "fast, accurate and ruthless" requires 3D printing mold workpieces and profit conversion with maximum cost performance, which has become a difficult problem for Party A's gods.

Additive manufacturing can quickly manufacture complex geometric parts according to the three-dimensional model of parts without cutting. It is a "bottom-up" incremental manufacturing method. This bottom-up processing method breaks away from the constraints of traditional manufacturing, and has a large degree of design freedom. It can realize batch and personalized customization, and can meet the design and preparation needs of complex molds.

Then, according to the technical characteristics, lock the keyword "personalized customization, mass production and complex structure", we summarize the characteristics and help customers get to the point quickly, accurately and ruthlessly.

01 mass production mould

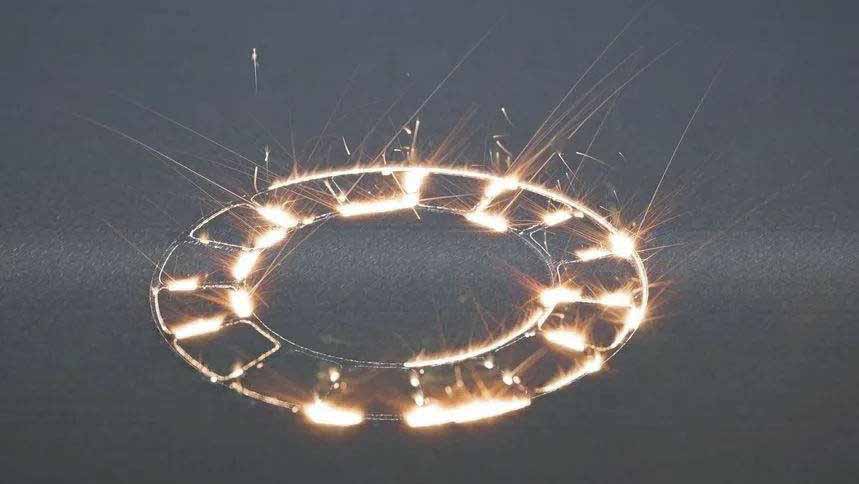

Customers have a large amount of injection products, need mass production, and time is tight, so it is necessary to shorten the injection cycle. The mold shaped waterway made by

3D printing technology can not only balance the mold temperature and improve the product yield, but also quickly shorten the cooling cycle of injection molding products and improve the production efficiency by evenly distributing the waterway in the mold cavity. The mold cooling time can be shortened to 30% ~ 45%, and individual products can reach more than 50%.

02 complex product structure

Secondly, with the improvement of economic level, the shape and structure of all kinds of injection molding products become more and more strange, such as various small convolution structures on the top of cosmetic bottle caps such as Dior and Estee Lauder, the deep frame inner cavity of automobile fuse box, etc. if the traditional molding method is used, the injection molding products with this structure can not get a better cooling effect at all, which will lead to defects such as sun marks, scalds, strains and so on at the rubber inlet of hot runner. The conformal waterway mold made by 3D printing technology can better avoid these problems, so as to minimize the production cost for customers.

03 multi deep reinforcement position of product

The deep rib position of the product is a headache in the mold manufacturing, because in order to ensure the forming of the deep rib part, a large amount of cooling time sometimes needs to be sacrificed. For example, in our early case, this problem is obvious in the inner wall of the automobile airbag mold, which will seriously lead to the long cooling time of the product and affect the production and delivery date of customers. By splitting the inserts and printing them one by one, we can make the waterway fully spread throughout the mold cavity, so as to perfectly solve the above problems.

04 high dimensional requirements

When the size requirements of injection molded products are high, the uneven mold temperature brought by the traditional waterway will affect the size of injection molded products. For some high value-added products, such as apple Bluetooth headset, the holding box not only plays the role of packaging, but also has the function of charging. When the headset is put into the holding box, it can be charged automatically. Therefore, the size requirements of the product are extremely strict.

For example: when the product deformation is required to be within 0.05mm, and the actual product deformation exceeds 0.05mm, to 0.1mm or more, the mold temperature can be balanced and the product deformation can be controlled through the conformal waterway.

Therefore, when choosing 3D printing of mold, please grasp several key points "mass production mold, complex structure, many deep reinforcement positions and high product size requirements". Because the current price of 3D printing is not cheap, the reason why we do not recommend customers to use 3D printing to make "helmet mold" is that the helmet mold has a very simple structure and large volume. There is no need to use 3D printing at all, and the traditional mold making can be well completed. If you insist on your own way, the expensive cost and little benefit will naturally outweigh the loss.

Mastars is a professional company specializing in prototyping, rapid prototyping, CNC parts processing, 3D printing, laser molding, manufacturing, mass production and mold reproduction, etc., to provide customers with comprehensive and professional product manufacturing needs.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China