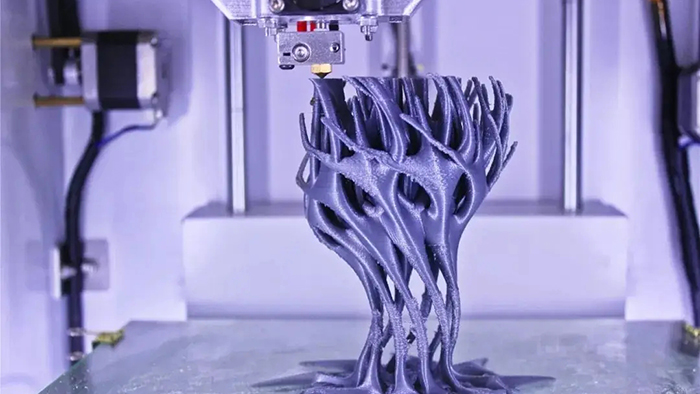

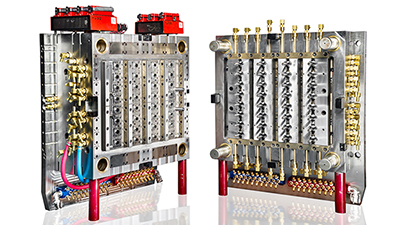

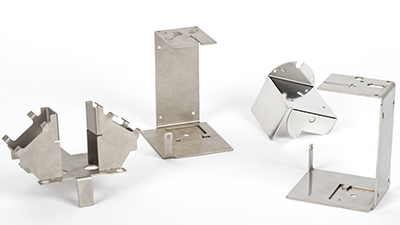

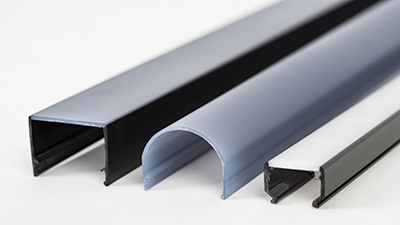

Toolmaking is part of Mastars vertically integrated offering, which means you can benefit from our extensive knowledge and understanding of the production and assembly process. Prototype tooling can be a cost-effective solution when it comes to creating complex and sophisticated moulds. Our prototype tooling service is a great opportunity for you to test the functionality of a component in low volumes.

-

Advantages to Mastars prototyping tooling serviceMastars has experienced tooling making engineers and machinists from all over the world. When you choose our rapid for quick turnaround mold tools, you get a host of services to support any project, including: > Design for manufacturing analysis

Advantages to Mastars prototyping tooling serviceMastars has experienced tooling making engineers and machinists from all over the world. When you choose our rapid for quick turnaround mold tools, you get a host of services to support any project, including: > Design for manufacturing analysis

> Overmolding

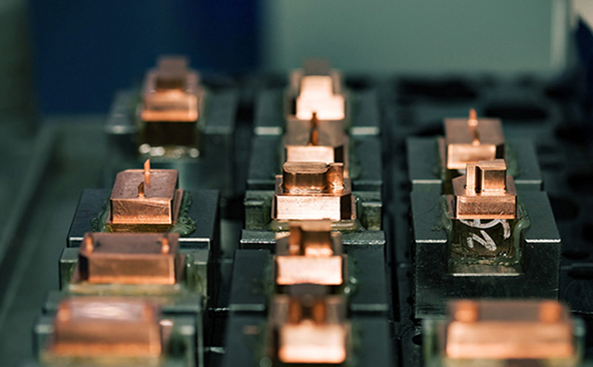

> Multiple cavities

> Inserts

> Heated cores

> Manual and hydraulic sliders -

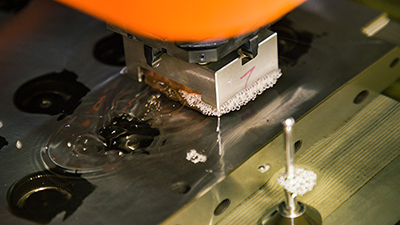

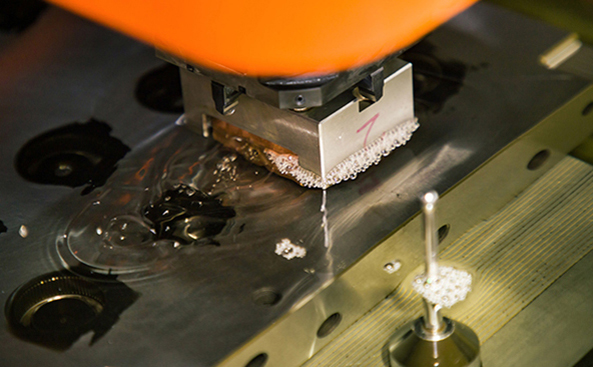

How we can helpWe fully understand the impact of tolerance management on your product assembly process and ensure that the service we provide is of the highest standard. Are able to validate tools in-house using our 3D co-ordinate measuring machine.

How we can helpWe fully understand the impact of tolerance management on your product assembly process and ensure that the service we provide is of the highest standard. Are able to validate tools in-house using our 3D co-ordinate measuring machine.

|

TOOL OPTIONS |

LEAD TIME |

PART QUANTITY |

MAXIMUM PARTING LINE MISMATCH |

MAXIMUM FLASH |

TOOL TOLERANCES LINEAR DIMENSIONS |

PART COLOR |

PART FINISH (COLOR) |

PART FINISH (TEXTURE) |

|

Rapid tool (Master unit die base) |

1.5-3 Weeks | 5,000 Shots | 0.010in | 0.010in | ±0.003 + 0.002in/in | Pantone colors | A2 | Yes |

|

Prototype tool (Stand alone) |

2-4 Weeks | 5,000-50,000 Shots | 0.010in | 0.007in | ±0.005 + 0.002in/in | A2 |

-

-

Wide range of applications. Fast, efficient, short production cycle, saving time cost. Adapt to diverse product needs. Accelerate product development and time-to-market. Multiple sets of molds are as easy to make as one set of molds, with good repeatability. Advantages of Mastars: The master mold can be processed with high precision and fast speed. Rapid prototyping services to meet various needs. Advanced CNC and EDM equipment, high production efficiency. Fast molds with complex shapes and fine structures can be made.