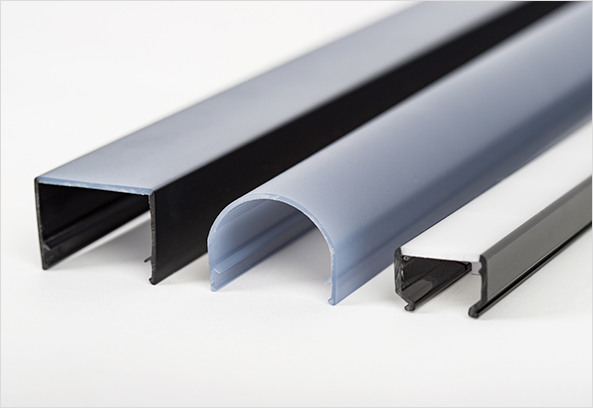

We specializes in developing custom extrusions to match your needs. We can take you from prototype lengths to production volumes. Our Fast-Track quote process allows us to get you a quick quote response. Multi-durometer and multi-color plastic extrusions are available.

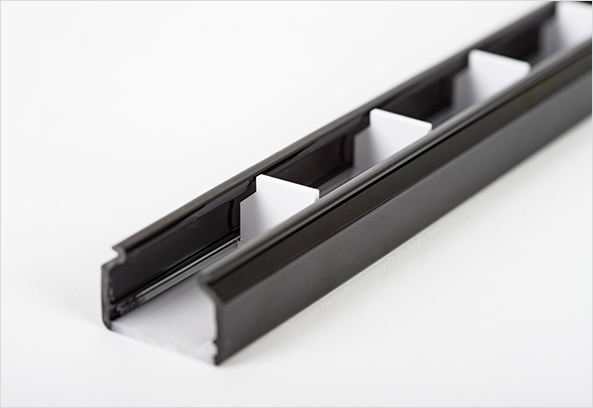

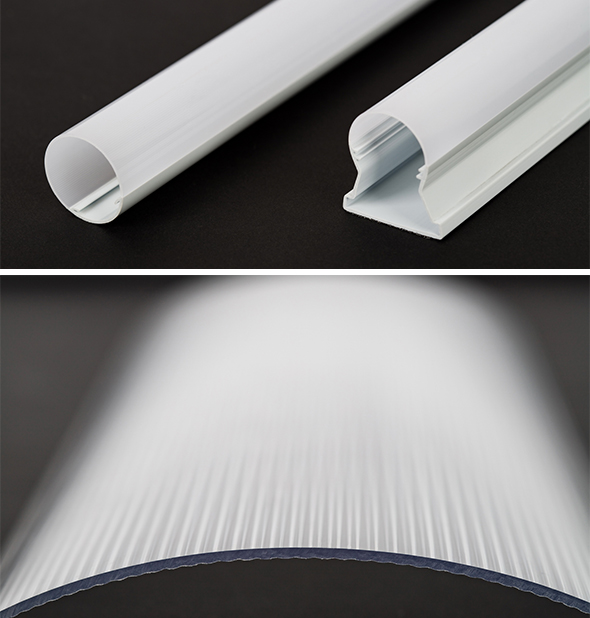

Mastars plastic extrusion specificationsWe can manufacture custom plastic profiles up to 22 1/2″ wide and 7″ tall. We also have the capability to extrude custom plastic tubing up to 4 inches round. We can hold tolerances of 0.010″ or better which exceeds most industry standards.> Taping heat > Hot stamping > Solvent bonding > Sawing & Slotting > Sealing & Cutting & Gluing > Punching & Coiling & Routing > Routing & Mitering & Embossing

Mastars plastic extrusion specificationsWe can manufacture custom plastic profiles up to 22 1/2″ wide and 7″ tall. We also have the capability to extrude custom plastic tubing up to 4 inches round. We can hold tolerances of 0.010″ or better which exceeds most industry standards.> Taping heat > Hot stamping > Solvent bonding > Sawing & Slotting > Sealing & Cutting & Gluing > Punching & Coiling & Routing > Routing & Mitering & Embossing

Mastars can extrude materials> Provista > Styrolux > Rigid PVC > ABS & FPVC > Polyethylene > Polypropylene > Polycarbonate & Polystyrene (HIPS) > Other Materials – By request

Mastars can extrude materials> Provista > Styrolux > Rigid PVC > ABS & FPVC > Polyethylene > Polypropylene > Polycarbonate & Polystyrene (HIPS) > Other Materials – By request

Our extrusion prototyping program can be quoted quickly from your 3D solid models or PDF files. First articles are available within 2-4 weeks.

Injection Molding Common Issues & Solutions

Injection Molding Common Issues & Solutions

Future Trends in the Injection Molding Industry: Digitization and Sustainability

Future Trends in the Injection Molding Industry: Digitization and Sustainability

What plastics are used in the exterior trim parts of a car?

What plastics are used in the exterior trim parts of a car?

pp plastics commonly used in automotive interior and exterior trim

pp plastics commonly used in automotive interior and exterior trim