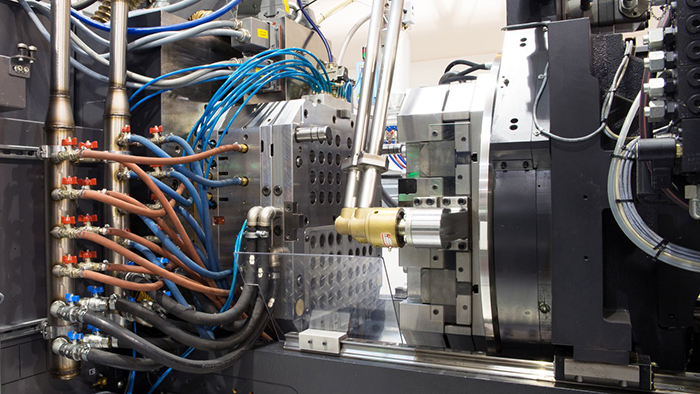

Mastars provides rapid prototyping services, injection mold design services, and also has injection molding machines of various sizes to meet your product needs. In this year's extreme high temperature weather, we should not only pay attention to our own heatstroke prevention and cooling, but also not ignore the machine. Mastars 24 hours constant temperature workshop provides a good production environment for your products

What are the problems of high temperature of injection molding machine?

1. Oil viscosity decreases

High temperature rise of injection molding machine will lead to lower viscosity of oil and increase leakage, and the volumetric efficiency of pump and the efficiency of the whole system will be significantly reduced.

2. Mechanical thermal deformation

The moving parts with different coefficients of thermal expansion in the hydraulic components become stuck due to the small gap between them, which affects the transmission accuracy of the hydraulic system and leads to poor quality of work of the components.

3. Deformation of rubber seals

High temperature rise of injection molding machine will make the rubber seal deformation, accelerating aging failure, reducing the sealing performance and service life.

4. Accelerate oil oxidation and deterioration

High temperature rise of injection molding machine will accelerate the oxidation and deterioration of the fluid, precipitating asphalt substances, reducing the service life of hydraulic fluid.

What should I do if the temperature of the injection molding machine is too high?

1. According to the different load requirements, often check and adjust the pressure of the relief valve, so that it is just right.

2. Select the hydraulic oil reasonably, especially the viscosity of the fluid, and try to use a lower viscosity to reduce the viscosity friction loss if the conditions allow.

3. Improve the lubrication conditions of moving parts to reduce friction loss, which is conducive to reducing the work load and heat generation.

4. Improve the assembly quality and precision of hydraulic components and hydraulic system, strictly control the clearance of the mating parts and improve the lubrication conditions. Use sealing materials with small friction coefficient and improve the sealing structure, reduce the starting force of the hydraulic cylinder as much as possible, in order to reduce the heat generated by mechanical friction loss.

What other matters need to be noted?

1. Cooling of the injection molding workshop

The temperature of the injection molding workshop itself is very high, generally can reach more than 30 degrees, in the case of the higher outside temperature, it is necessary to adjust the temperature of the workshop with air conditioning.

2. Hot weather is likely to cause electric shock accidents

Inadequate protective measures, non-professional workers operating in violation of the law or high temperature easily sleepy may lead to electrocution. It is also necessary to check the electric wire of the injection molding machine frequently because the high temperature and high humidity in summer can easily corrode the wire.

3. Whether the fan in the electric box and motor is running normally

If the fan in the electric box and motor of the injection molding machine is running normally, please replace it in time to avoid the motor burning out due to high temperature.

4. Whether the cooler is running normally

Is the cooler of the injection molding machine running normally, is the cooling water pipe blocked, if the water quality is not good, it needs to be cleaned frequently, otherwise it will lead to high temperature of the injection molding machine.