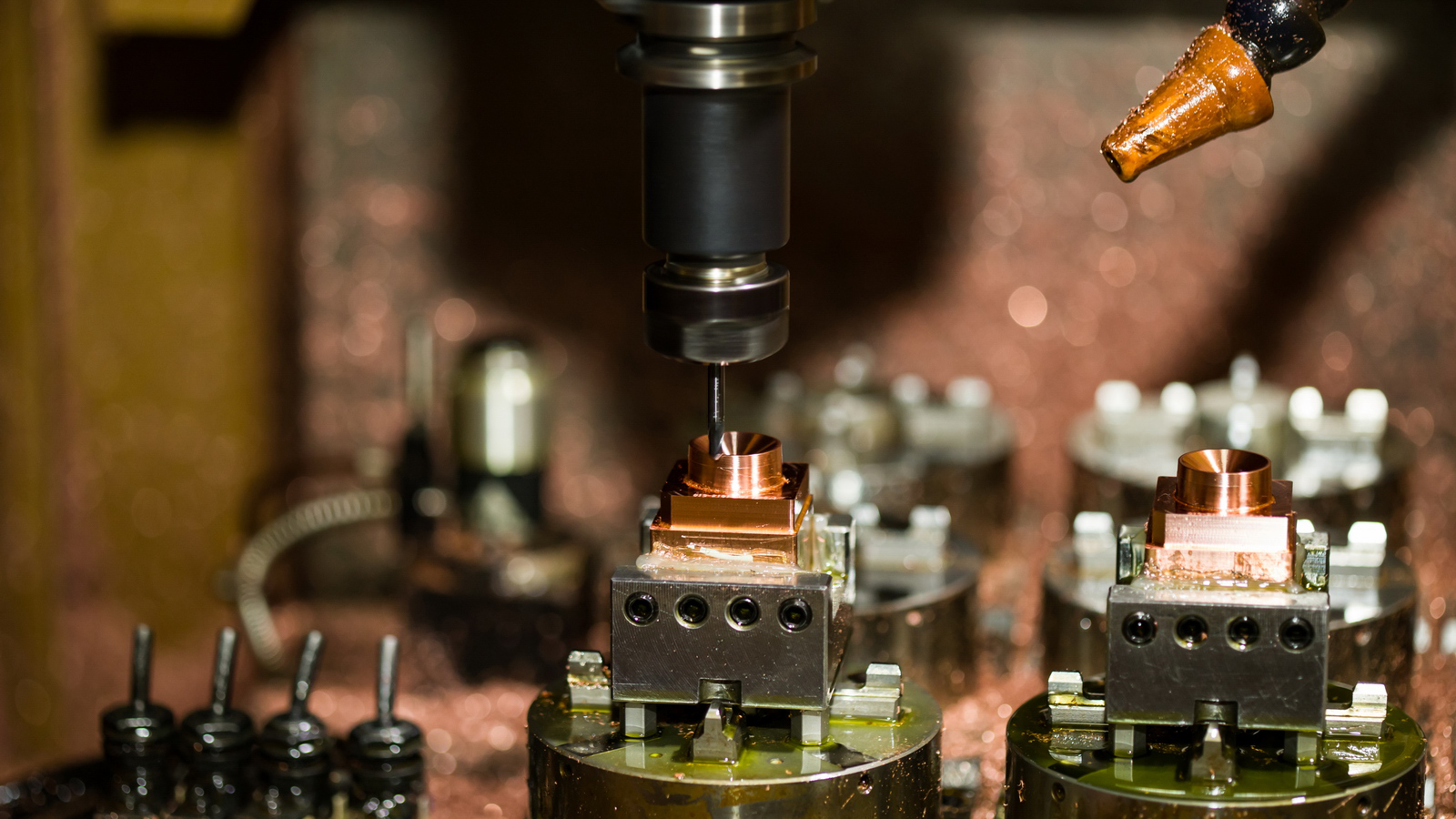

Mastars as a

metal prototype maker, provides

rapid sheet metal prototyping,

rapid CNC service.rapid prototyping.With the improvement of modern industrial technology, the demand for high-precision workpieces is gradually increasing. In the production activities, it is often encountered that the workpieces have certain deformation after processing, resulting in poor matching with the pre-designed matching parts; Thus, a certain degree of production and processing costs are wasted, and even a series of engineering failures and accidents are caused; However, how to improve the processing quality and reduce the error is an important guarantee to improve the workpiece quality. In this issue, mastars CNC precision machining manufacturer will give a detailed description of the special topic "control technology to reduce part deformation".

Cause analysis and control of deformation

1. Deformation caused by redistribution of internal stress after part processing.

2. The flatness of the locating surface fails to meet the requirements, resulting in the deformation caused by springback.

3. Deformation caused by improper clamping position, direction and stress point of parts.

4. Machining allowance of parts and deformation caused by cutting force during machining.

5. Deformation caused by cutting heat during machining.

6. Deformation caused by unreasonable part structure.

Part deformation control method

1. Stress relief and deformation control through heat treatment. It is divided into rough machining, semi finishing and finishing processes. Heat treatment, stress relief and stabilization treatment are added in the middle to release the processing stress and material stress of parts and improve the stability of dimensional accuracy of parts after finishing.

2. Finish machining locating surface to control deformation. Finish machining datum surface by grinding, grinding and other methods to improve the accuracy of locating surface and prevent springback deformation.

3. Improve pressing clamping to control deformation. Control the deformation by changing the clamping position, direction and force point, such as changing the radial compression to axial compression.

4. Reduce cutting force to control deformation. In the finishing process, grinding, polishing and other machining methods with small cutting force can be used, and the methods of changing cutting parameters and reducing cutting parameters can also be used.

5. Reduce cutting thermal control deformation. In order to prevent thermal deformation caused by cutting heat, cutting fluid can be used in machining and cutting parameters can be reduced.

6. Improve part structure or process method to control deformation. Reduce or control part deformation by improving part structure, such as adding support ribs, symmetrical shape design, etc; Improve the process method to completely release the stress.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China