Mastars provide rapid cnc services,rapid cnc machining,rapid prototyping services.It enjoys a high reputation in terms of stability while maintaining a dynamic, supportive and flexible spirit.

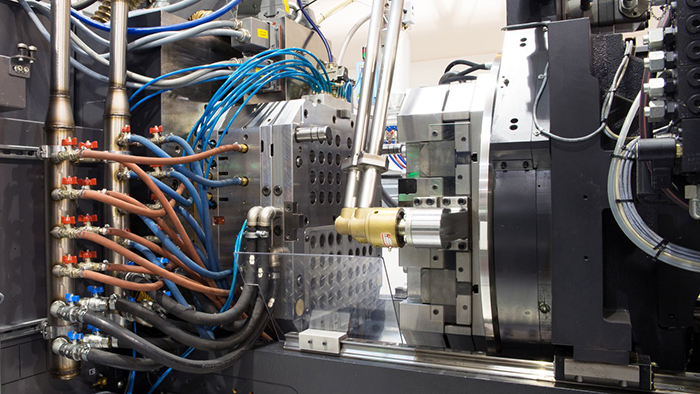

Injection molding is a widely used manufacturing process in the medical industry, offering a variety of applications. Medical grade plastic injection molding is used for medical devices, components, laboratory and facility equipment, etc. One of the main advantages of the injection molding process is the ability to meet the stringent specifications and regulatory requirements of the medical industry.

Benefits of Medical Device Injection Molding

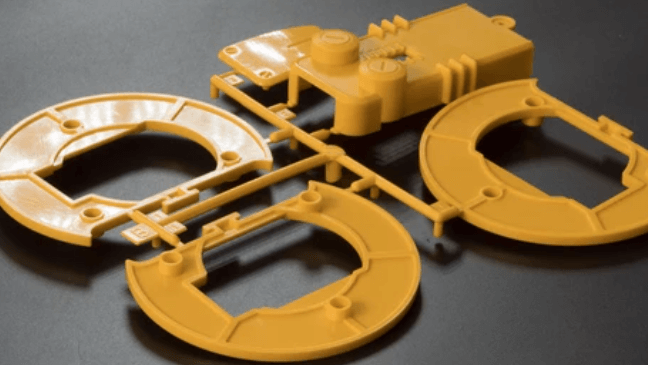

Medical suppliers have found that plastic injection molding of medical parts, components and devices is one of the most effective ways to obtain the required quality and specifications in a cost effective manner. Medical device plastic injection molding is used for devices such as

Implant components

Beakers, test tubes and other containers

Housings for medical and laboratory equipment

Surgical equipment and components

Drug delivery devices and components

Orthopedics

These are just a few of the ways in which plastic injection molding of medical devices can be used. The process of plastic injection molding can be used for high-volume production of virtually any part that needs to be durable and easily sterilizable, and produced with excellent precision.

With injection molding, suppliers and manufacturers to the medical industry can gain several advantages of the process and available materials. These advantages include

Cost-effectiveness - The nature of injection molding makes it one of the more cost-effective manufacturing processes, especially for high-volume production. Plastic injection molding is the most cost-effective option when medical parts, components and devices are needed in volume.

Superior Accuracy Assurance - Tolerance production is critical in medical device manufacturing, as millimeters or microns can affect the successful performance of a component. Skilled plastic injection molding equipment is capable of producing a large number of parts and devices with extremely high precision and negligible part-to-part variation.

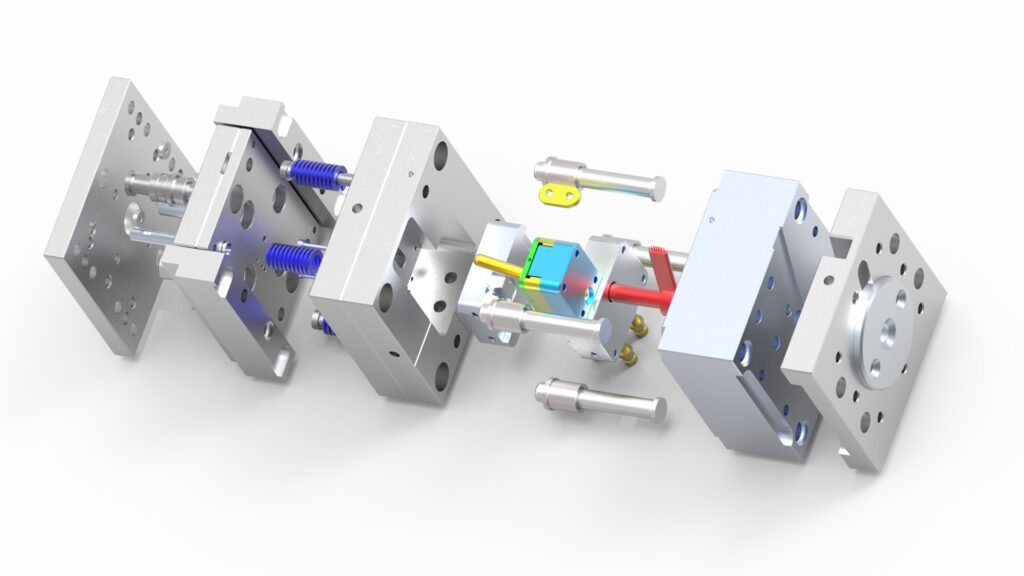

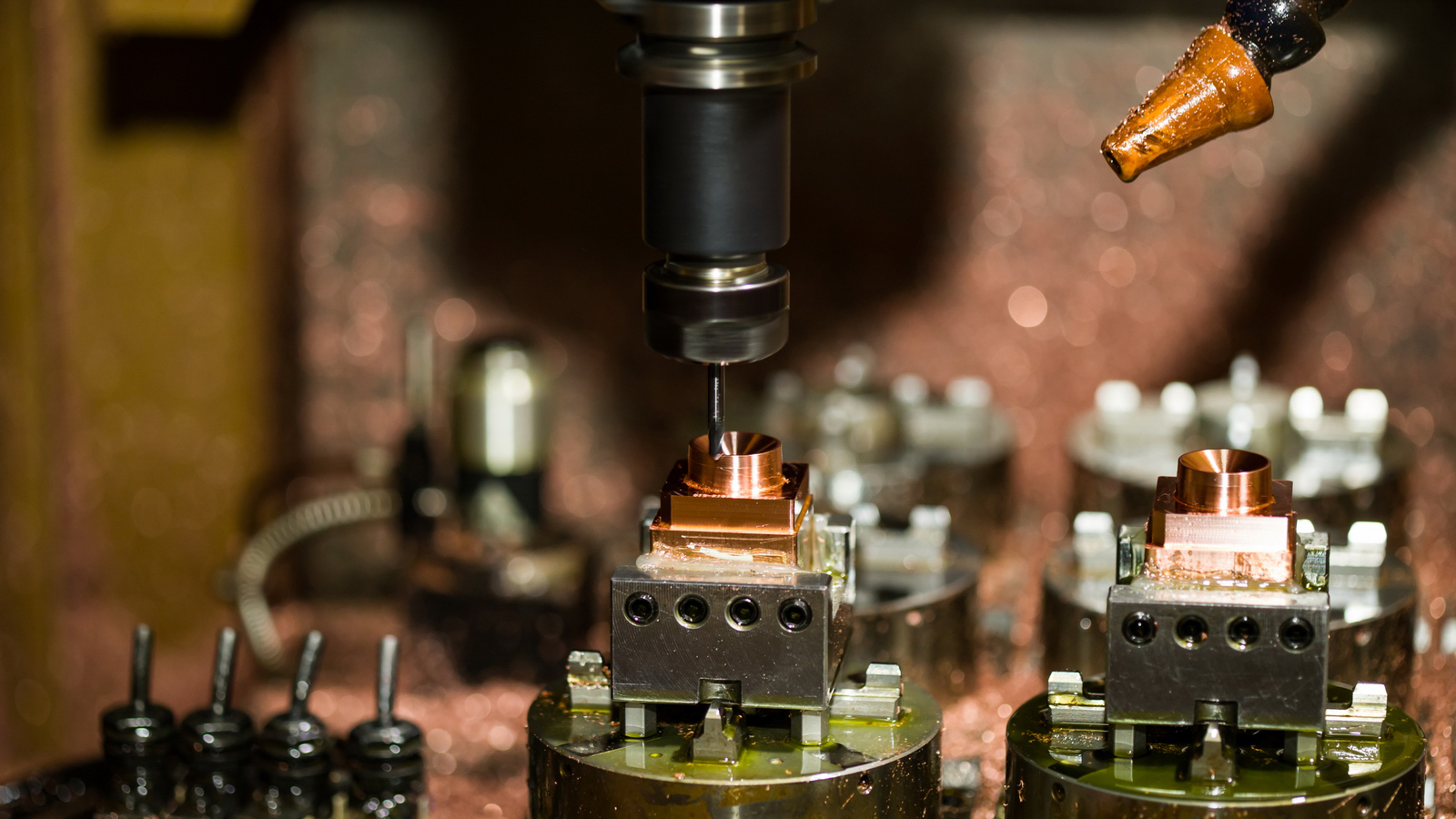

Mastars is a one-stop solution provider for

precision injection molding design, manufacturing, and injection molding. In the mold industry for many years, specializing in more technological high-end mold manufacturing technology, has successfully obtained a number of patented technologies. If you are interested in our services or need any technical support, please contact us and we will be happy to share our knowledge of plastic injection molding and provide you with an economical plastic injection molding solution that fits your needs.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China