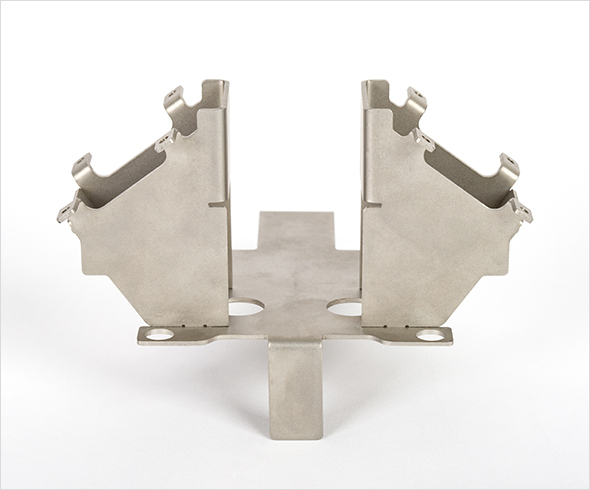

Years of experience with contract stamping projects a wide range of industries have honed our skills to provide you with the toughest components needed for your project. Our fully equipped facility and experienced staff use progressive and compound tools, either built in-house or customer supplied, for contract stamping projects. We turn out close-tolerance, complex parts, delivered to print specifications within pre-defined time frames. Our commitment to customer service will ensure your continued business success as well. The proof is in the final product.

In-House service Specialty integrated services metal stamping specializes in low to medium/high volume precision stampings and cutting blades for products such as electrical contacts, circuit boards, and cutting blades. > 15 to 400 ton presses > Compound and progressive tooling > Materials as thin as .003″ > Exotic materials > In house die building > Complex stampings

In-House service Specialty integrated services metal stamping specializes in low to medium/high volume precision stampings and cutting blades for products such as electrical contacts, circuit boards, and cutting blades. > 15 to 400 ton presses > Compound and progressive tooling > Materials as thin as .003″ > Exotic materials > In house die building > Complex stampings

| Electrical contacts, stamped |

Miniature and micro-miniature electrical contacts Wide variety of alloys, including precious metals Able to hold very tight tolerances Medical and defense industry |

| Circuit board stamping |

Flexible Fiberglass Aluminum |

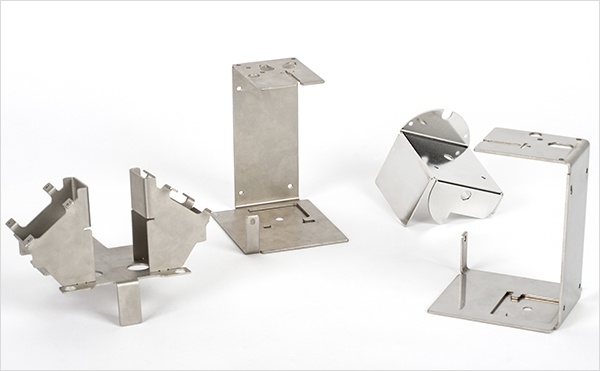

| Complex stampings |

.003” foil to .250” thick Progressive and compound tools a specialty |

| Creep feed grinding |

Finished parts in a single pass Excellent for pre-hardened materials |

| Supplementary operations |

To offer the best possible lead times we have in-house capabilities to provide:

Cleaning Vibratory deburring Passivation Harperizing Packaging |

| Materials |

We are experienced with a wide variety of materials and will work with customer supplied materials when needed. We commonly run:

Aluminum Brass Bronze Copper Beryllium copper Steel Stainless steel Exotics including platinum, gold, others Plastics |

| Engineering |

AutoCAD SolidWorks UX |

Vehicle Body Reduction Hope - Hot Stamping

Vehicle Body Reduction Hope - Hot Stamping

Surface treatment technology of precision parts|Custom metal stamping

Surface treatment technology of precision parts|Custom metal stamping

characteristics of metal stamping die|Custom metal stamping|Mastars

characteristics of metal stamping die|Custom metal stamping|Mastars

Material selection precautions of metal stamping die|rapid prototyping services

Material selection precautions of metal stamping die|rapid prototyping services