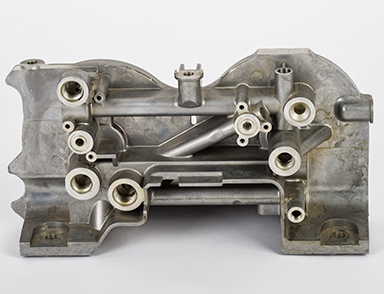

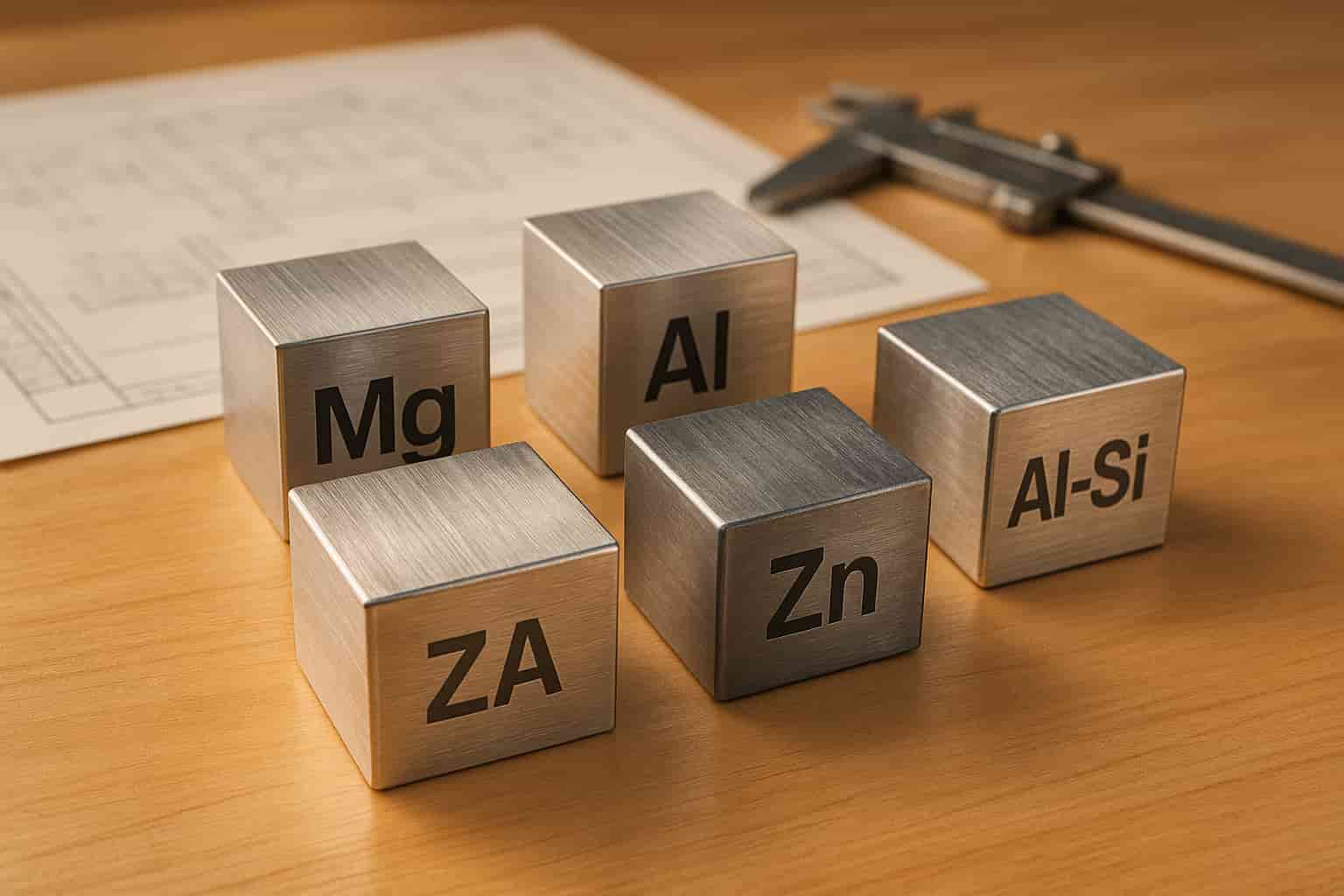

For mass production of relatively complex metal parts, die casting is the most suitable manufacturing process. Die-cast components are manufactured by steel mold. The raw material used in injection molding is plastic, while in die casting, metals with low melting points are used, such as zinc and aluminum. Die casting has become a common process due to its excellent accuracy, reliability, repeatability and versatility.

In the die casting process, high air pressure or hydraulic pressure forces molten metal into a steel casting or die that produces metal parts with complex geometries. Most of the metal parts involved in all casting processes can be produced through the die casting process.

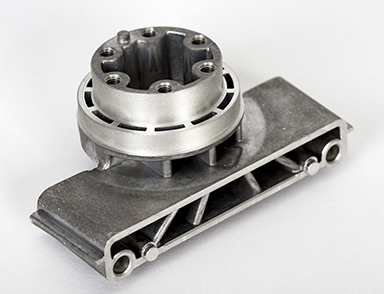

Mastars die castings has been developing zinc and aluminum cast components over 20 years. Refinements in both the alloys and the process have expanded our applications to most market sectors. Size, shape, thickness, strength and precision combine to offer designers unsurpassed qualities in performance and visual aesthetics.

Hot and cold chambers are our advantage. A complete die casting cycle can vary from less than one second for small components weighing less than one ounce, ranging from-two to-three minutes for a casting of several pounds, making die casting the fastest technique for producing precise non-ferrous metal parts.

Here’s why you should consider using our die casting process > Easier inventory control and reduced labor cost > Obtain tighter tolerances and produce high-fidelity copies with dimensional stability > Fast turnaround and production times > Reduction in material waste > Long tool life with aluminum, zinc and magnesium alloys > Excellent surface finish and reduced need for post-machining > Cost savings when carrying out large production

Here’s why you should consider using our die casting process > Easier inventory control and reduced labor cost > Obtain tighter tolerances and produce high-fidelity copies with dimensional stability > Fast turnaround and production times > Reduction in material waste > Long tool life with aluminum, zinc and magnesium alloys > Excellent surface finish and reduced need for post-machining > Cost savings when carrying out large production

Perfect die casting machinesMastars has 6 sets of 88T-500T die-casting machines, which can adapt to the production of parts of different sizes. The main raw materials are aluminum alloy and zinc alloy.

Perfect die casting machinesMastars has 6 sets of 88T-500T die-casting machines, which can adapt to the production of parts of different sizes. The main raw materials are aluminum alloy and zinc alloy.  One-stop servicesThe surface treatment of products after die casting includes polishing, anodizing, powder coating, plating and E-Coating. From die sinking to delivery, all in one stop, which not only saves customers' precious time, but also helps to control each link and quality in production, and achieve higher cost performance.

One-stop servicesThe surface treatment of products after die casting includes polishing, anodizing, powder coating, plating and E-Coating. From die sinking to delivery, all in one stop, which not only saves customers' precious time, but also helps to control each link and quality in production, and achieve higher cost performance.

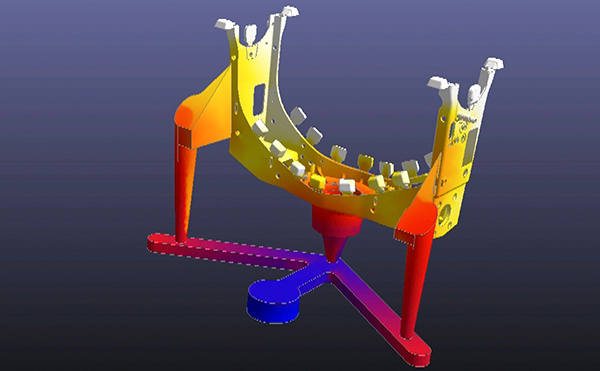

Experienced design teamMastars is a global industrial manufacturing service company, with a strong design team and more than ten years of experience in cooperation with global industry leaders. Designing and manufacturing complex die-casting products is our advantage. 3D drawings and mold flow analysis provide customers with higher-end and more accurate product development and design.

Experienced design teamMastars is a global industrial manufacturing service company, with a strong design team and more than ten years of experience in cooperation with global industry leaders. Designing and manufacturing complex die-casting products is our advantage. 3D drawings and mold flow analysis provide customers with higher-end and more accurate product development and design.

Professional testing equipment Professional testing equipment to ensure the production quality of products. Our testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Sacn III Blue ray 3D scanner, Swedish Hexagon CMM, 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan Mitohiro Roughness Meter, etc. All this ensure that your products meet the design and functional requirements.

Professional testing equipment Professional testing equipment to ensure the production quality of products. Our testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Sacn III Blue ray 3D scanner, Swedish Hexagon CMM, 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan Mitohiro Roughness Meter, etc. All this ensure that your products meet the design and functional requirements.

Mastars offers an all-in-one set of die casting services. From mold production to die casting, machining, post-machining and finishing, our engineers offer design solutions that fit your end-use and functionality. All of our experts are versed in a range of industries including consumer electronics, healthcare, automotive, aerospace, education, spares and more.

We urge you to get in touch with our engineering team anytime and take advantage of our excellent professional services at over stringent quality standards.

Top 5 Die Casting Alloys for Corrosion Resistance

Top 5 Die Casting Alloys for Corrosion Resistance

The difference between die-casting mold and plastic mold|rapid cnc service

The difference between die-casting mold and plastic mold|rapid cnc service

Knowledge of aluminum alloy die casting process|Mastars|rapid cnc machining

Knowledge of aluminum alloy die casting process|Mastars|rapid cnc machining

Five factors affecting the quality of die castings|rapid prototyping service

Five factors affecting the quality of die castings|rapid prototyping service