In terms of industrial manufacturing, rapid prototyping, rapid sheet metal prototypes, 3D printing prototyping, precision manufacturing, precision CNC machining, high-precision molds, die casting, vacuum casting and other technical processes are used to achieve all-round rapid prototyping and production of high-precision products.

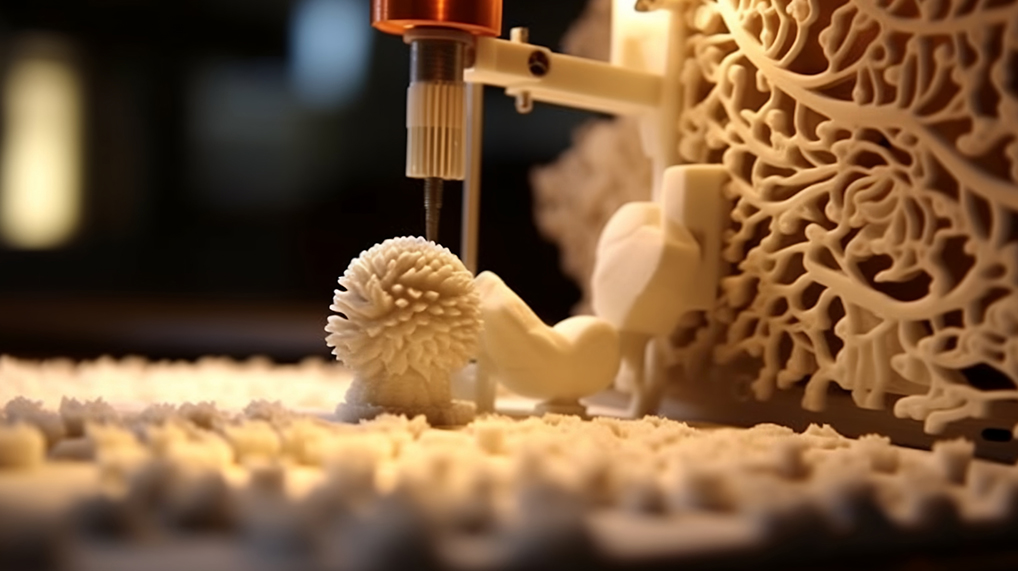

The medical device industry continues to grow all over the world. With the development of the industry, 3D printing of medical device prototypes and production parts is also developing. Medical 3D printing is no longer a science fiction thing. Additive manufacturing (AM) is now used in everything from surgical implants to Prosthetics and even organs and bones.

1、 Advantages of 3D printing for medical purposes

3D printing has achieved an unprecedented level of customization. Everyone's body is different, and 3D printing allows engineers to customize products according to these differences. This increases the comfort of patients and the accuracy of surgery. Most importantly, 3D printing can usually realize customized medical applications at a lower cost than traditional manufacturing.

2、 3D printing technology for medical treatment

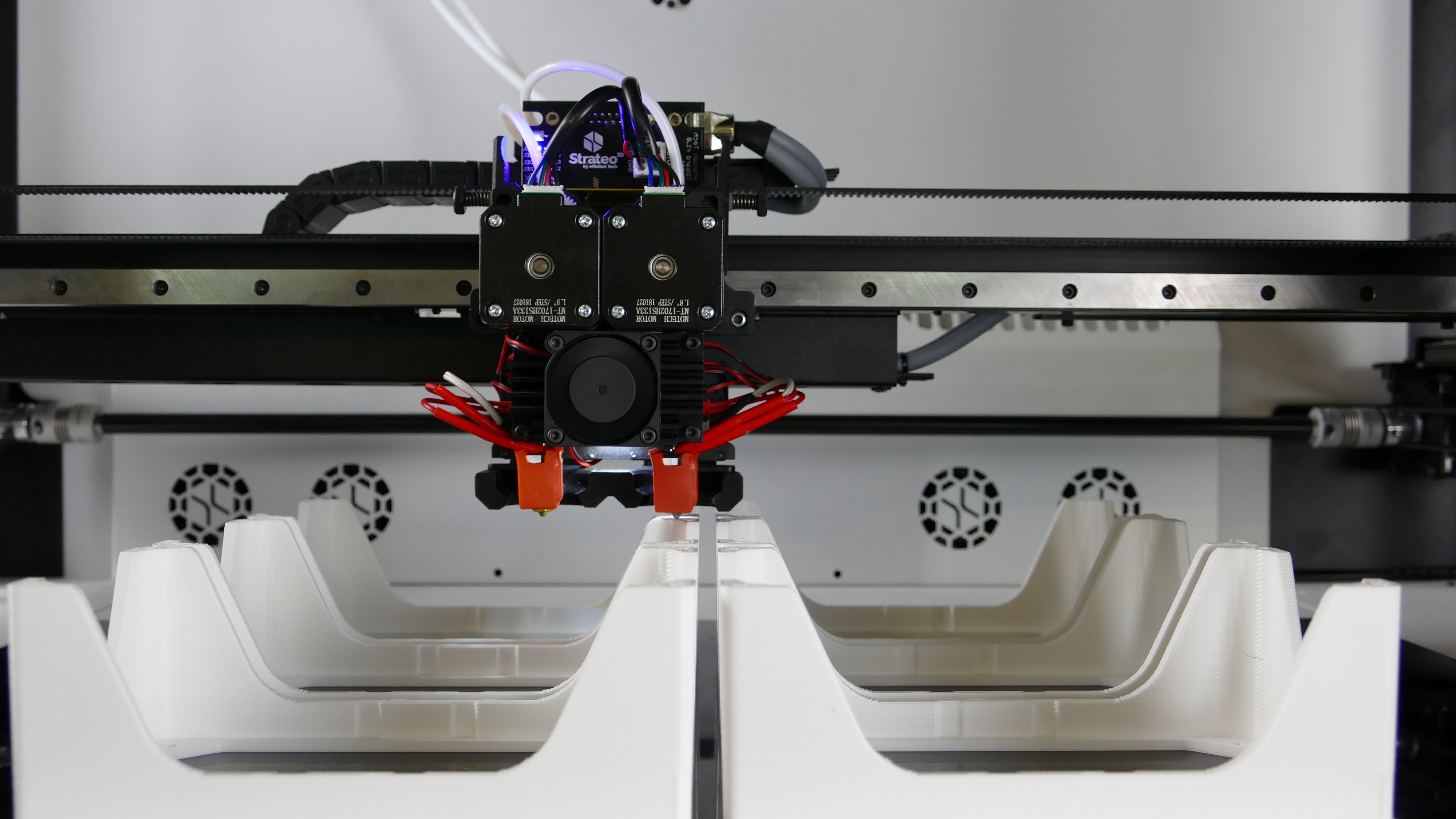

Both metal and plastic 3D printing technologies are suitable for medical applications. The most common technologies include Fused Deposition Modeling (FDM), Direct Metal Laser Sintering (DMLS), Digital Light Synthesis (DLS) and Selective Laser Sintering (SLS).

FDM is a good process for early equipment prototype and surgical model. Sterilized FDM materials include ppsf, ULTEM and ABS m30i. Metal 3D printing through DMLS can be completed with 17-4PH stainless steel, which is a sterilizable material. Carbon fiber is also a new process, which uses custom resin for various medical devices. Finally, SLS can produce strong and flexible parts, which is the best process used to create bone replicas.

3、 3D printing used in the medical industry

1). Implants:

Cutting edge technology now allows 3D printing of organics, such as cells used in tissues, organs and bones. For example, orthopaedic implants are used for bone and muscle repair. This helps to improve the availability of implants. 3D printing is also good at making fine lattices that can be placed outside surgical implants, which helps to reduce the rejection rate of implants.

2). Surgical tools:

It is especially effective in the field of dentistry. 3D printing tools meet the unique anatomical structure of patients and help surgeons improve the accuracy of surgery. Plastic surgeons also often use guides and tools made by 3D printing.

3). Surgical planning and medical training model:

Future doctors now often practice on 3D printing organs, which can simulate human organs better than animal organs. Now doctors can print out exact copies of patients' organs, making it easier to prepare for complex surgery.

4). Medical equipment and tools:

3D printing can also produce conventionally manufactured tools such as clips, scalpels and tweezers in a more sterile form and at a lower cost. 3D printing also makes it easier to quickly replace these damaged or aging tools.

Mastars:

As a metal prototype maker, we employ proven prototype technologies(rapid CNC services, sheet metal prototyping, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Our purpose is to make great products for our customers that create value and improve people's lives. We help a diverse customers base design, build and deliver the products that make the world a better place.

Our vision is to be the most reliable and valuable manufacturer supplier in the world.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China