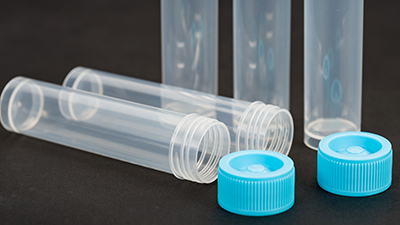

- [Medical Device Industry]Solution for Medical and health parts06 Jan,2022

- The automotive industry represents a large part of the customer base and we believe to provide the highest quality solution for our customers. Our goal is to exceed your expectations and help you succeed in the market – this mission makes our customers trust.

- [Household Appliances Industry]Household Appliances Industry21 Dec,2021

- Mastars produced injection molds and tooling and decorative paint finishes for domestic and business-machine enclosures. Mastars's experience covers a wide range of domestic and commercial applications, from vacuum air to digital printers.

- [FAQ]Manufacturing: A Detailed Overview31 Oct,2025

- This article is a brief introduction to manufacturing, including manufacturing definition, manufacturing process

- [FAQ]Glossary of Plastic Injection Molding Terms31 Oct,2025

- An A to Z guide to terminologies in Injection tooling.Here is a detailed English-language guide to the professional terminology associated with Injection Tooling (the mold). This glossary is organized by the function and location of components within the mold system.

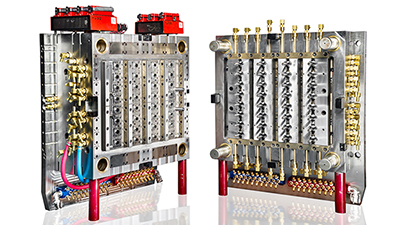

- [FAQ]Injection Tooling: A Detailed Overview31 Oct,2025

- Article about Injection tooling,Injection tooling defination, Injection tooling process,Injection tooling advantage and shortage.

- [FAQ]Terminology of the Injection Molding Industry31 Oct,2025

- Common Terms Within The Injection Molding Industry.Plastic injection molding is a manufacturing process wherein plastic is injected into aluminum, or steel molds and squeezed under high pressure to come up with the desired shape of the product

- [FAQ]Mastars: Detail Guide About Aluminum Injection Molding16 Mar,2022

- Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the injection molding technique. Mastars is also a metal prototype maker.

- [FAQ]What are the characteristics of stainless steel forging process?|prototype maker16 Apr,2022

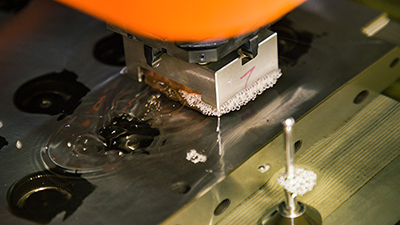

- Mastars is a global manufacturer of plastic and metal products from prototype design to mass production for many Fortune 500 enterprises. The production process includes CNC processing, vacuum casting, 3D printing, sheet metal, forging, extrusion, etc.

- [Blog]Injection Molding Common Issues & Solutions23 Aug,2025

- Injection moulding defects like warping, sink marks, and short shots increase costs and risks. Solutions include precise machine adjustments, material selection, and advanced quality control tools for consistent, high-quality production.

- [News]Automotive Speed-Warning Devices , Choice or Necessity?23 Sep,2024

- All new vehicles in the European Union need to have speed-warning devices. California is getting ready to do the same.

- [FAQ]Understand high precision mold design|rapid cnc machining|metal prototype maker05 May,2022

- High precision plastic molds have relatively high requirements for design, and the complexity of mold design is higher than that of general molds. So what problems should we pay attention to in the design of high-precision plastic mold? Mastars will show you. (metal prototype maker,rapid cnc services??)

- [News]The development potential of China's mold market is huge13 Nov,2022

- It is understood that plastic moulds in China's mould industry can account for up to 30%. Driven by high technology and the demand for applications in the pillar industries, the plastic mould industry has formed a huge industrial chain.

- [News]Evonik launched three new light curing resins for 3D printing11 Nov,2022

- Evonik is launching three new INFINAM? photosensitive resin products for industrial-grade applications in 3D printing to expand the portfolio of photosensitive resins for common curing 3D printing processes, such as SLA or DLP, launched last year. In less than two years

- [News]3D printing creates highest specific strength titanium alloy28 Sep,2022

- Writing in the latest issue of Nature Materials, a team of Australian engineers say they have used 3D printing for the first time to obtain the highest specific strength titanium alloy to date, a major leap forward for the aerospace, defense, energy and biomedical industries. |metal 3d printing services

- [FAQ]Problems needing attention in transparent plastic injection molding13 Sep,2022

- Mastars is a large plastic mold manufacturer specializing in the production and processing of plastic molds and plastic products. It is committed to providing professional injection molding and plastic mold manufacturing,custom metal stamping, rapid cnc services.

- [Blog]The combination of injection molding and 3D printing - pellet 3D printing13 Aug,2022

- Mastars specializes in the design and manufacture of automotive interior and exterior trim and home appliance panels, providing parts design, structural design, mold manufacturing, and injection molded parts for automotive interior and exterior trim.

- [Blog]The world's largest automobile factory|automotive parts|mold08 Aug,2022

- Mastars manufactures high-quality and highly accurate products for the automotive, electronics, medical and outdoor industries. On the automotive side, manufacturing includes interior models, grilles, headlights, taillights, machined acrylic or dimensional lights, lighting, etc.Services offered are rapid cnc machining,sheet metal prototyping