We provide a variety of precision CNC machining services that includes milling, turning and surface grinding. Whether you’re designing parts that demand high volumes or only running trials with prototypes for low-volume production, our CNC machining services are available to avail you iterative development with quick turnaround and consistency in quality. Both of these processes CNC Turning and CNC milling are designed to achieve specific aims in manufacturing from jigs and fixtures to parts with cylindrical properties, holes, slots and grooves.

CNC milling serviceWe offers a range of CNC milling processes to produce precise and complex parts with high-dimensional tolerances:> Carving machine

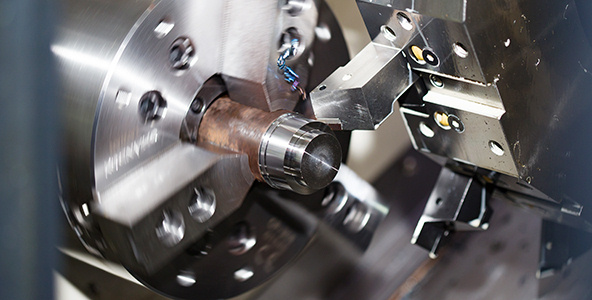

CNC milling serviceWe offers a range of CNC milling processes to produce precise and complex parts with high-dimensional tolerances:> Carving machine CNC turning serviceOur CNC turning process is highly optimized for the production of end-use production parts and customized models. With the aid of our CNC Lathe and live tooling additions, we achieve the machining of features such as grooves, flats, radial holes, axial and slots in as fast as 24 hours.> General car/lathe

CNC turning serviceOur CNC turning process is highly optimized for the production of end-use production parts and customized models. With the aid of our CNC Lathe and live tooling additions, we achieve the machining of features such as grooves, flats, radial holes, axial and slots in as fast as 24 hours.> General car/lathe Grinding machining > It can process materials with higher hardness, such as quenched steel, cemented carbide, etc. It can also process brittle materials, such as ceramics, glass, and granite.

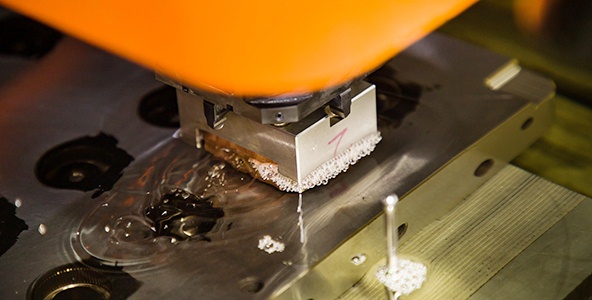

Grinding machining > It can process materials with higher hardness, such as quenched steel, cemented carbide, etc. It can also process brittle materials, such as ceramics, glass, and granite. EDM (Electrical Discharge Machining) > Its machining accuracy is high.

EDM (Electrical Discharge Machining) > Its machining accuracy is high.| Tolerance lever | Overall dimension range | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| Tolerance standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Leading equipmentWe have more than 80 sets of precision CNC machining centers, including German HERMLE 5-axis CNC machining center, AGIE Electrical Discharge Machine, Sodick Electrical Discharge Machine, Okuma, FANUC and other precision equipment, which can process various materials and any complex shapes, and the machining accuracy can reach 0.002mm, while the output and delivery time can be guaranteed.

Leading equipmentWe have more than 80 sets of precision CNC machining centers, including German HERMLE 5-axis CNC machining center, AGIE Electrical Discharge Machine, Sodick Electrical Discharge Machine, Okuma, FANUC and other precision equipment, which can process various materials and any complex shapes, and the machining accuracy can reach 0.002mm, while the output and delivery time can be guaranteed.

Rich industry experienceMastars has more than 20 years of manufacturing experience in the automotive, medical, electronics, daily necessities, new energy, outdoor sports and other industries, and maintains long-term and in-depth cooperation with more than 800 world-renowned companies including the world's top 500. We have a very good understanding of the materials and machining parameters of CNC machining, and can give useful suggestions. In the prototyping stage, from design to machining, we will put forward suggestions for improvement, so as to save a lot of time and make fewer mistakes in mass production. Even in product assembly, we will use our technological advantages to produce different products. For example, the external material of this part in the figure is PEEK, and the internal material is PTFE. After precision machining by CNC, they are assembled by using their different thermal expansion coefficients according to the principle of thermal expansion and contraction. Without using other fixed structures, the combination of the two is extremely tight. The requirements for the machining accuracy and the precise calculation of the expansion coefficient are very high.

Rich industry experienceMastars has more than 20 years of manufacturing experience in the automotive, medical, electronics, daily necessities, new energy, outdoor sports and other industries, and maintains long-term and in-depth cooperation with more than 800 world-renowned companies including the world's top 500. We have a very good understanding of the materials and machining parameters of CNC machining, and can give useful suggestions. In the prototyping stage, from design to machining, we will put forward suggestions for improvement, so as to save a lot of time and make fewer mistakes in mass production. Even in product assembly, we will use our technological advantages to produce different products. For example, the external material of this part in the figure is PEEK, and the internal material is PTFE. After precision machining by CNC, they are assembled by using their different thermal expansion coefficients according to the principle of thermal expansion and contraction. Without using other fixed structures, the combination of the two is extremely tight. The requirements for the machining accuracy and the precise calculation of the expansion coefficient are very high.

Production capacityMastars produces more than 1,000 sets of precision molds, 1 million prototypings, and more than 30 million mass-produced parts every year. The products are all over the world, involved in all walks of life, involving all kinds of materials and processes. Our strong production capacity enables us to calmly respond to customers' various production needs and meet their delivery dates.

Production capacityMastars produces more than 1,000 sets of precision molds, 1 million prototypings, and more than 30 million mass-produced parts every year. The products are all over the world, involved in all walks of life, involving all kinds of materials and processes. Our strong production capacity enables us to calmly respond to customers' various production needs and meet their delivery dates.

Design team and process controlWe have a professional design team of more than 35 people. Both product managers and project managers have PMP certificates(Project Management Professional Certification) and have rich theoretical and practical experience. Together with NPI(New Product Introduction) engineers and professional technicians, we work on all technologies, such as prototyping improvement, mold design and analysis, and mass production. Provide strong technical support and professional process control to ensure that your product production is always on the right track. Routine quality control is carried out through flowcharts, control plans, PFMEA, inspection instructions, etc. MES(Manufacturing Execution System) system and Kingdee ERP system control the entire process of production and finance, and promote efficient and scientific enterprise management.

Design team and process controlWe have a professional design team of more than 35 people. Both product managers and project managers have PMP certificates(Project Management Professional Certification) and have rich theoretical and practical experience. Together with NPI(New Product Introduction) engineers and professional technicians, we work on all technologies, such as prototyping improvement, mold design and analysis, and mass production. Provide strong technical support and professional process control to ensure that your product production is always on the right track. Routine quality control is carried out through flowcharts, control plans, PFMEA, inspection instructions, etc. MES(Manufacturing Execution System) system and Kingdee ERP system control the entire process of production and finance, and promote efficient and scientific enterprise management.

One-stop serviceWe have a complete production process capacity. Mastars provides comprehensive consultation and services from prototyping to mold design and mass production. You only need to place an order and wait for the satisfactory product to be received. And no matter what kind of material and what kind of craftsmanship is used, it can be done by Mastars. In production, from blanking, roughing, semi-finishing, finishing, surface treatment to final inspection, we can complete it with high quality and high efficiency until we produce qualified products.

One-stop serviceWe have a complete production process capacity. Mastars provides comprehensive consultation and services from prototyping to mold design and mass production. You only need to place an order and wait for the satisfactory product to be received. And no matter what kind of material and what kind of craftsmanship is used, it can be done by Mastars. In production, from blanking, roughing, semi-finishing, finishing, surface treatment to final inspection, we can complete it with high quality and high efficiency until we produce qualified products.

Advanced testing equipmentOur testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Scan III Blue ray 3D scanner, Swedish Hexagon CMM 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan MitutoyoRoughness Meter, etc. All this ensure that your products meet the design and functional requirements.

Advanced testing equipmentOur testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Scan III Blue ray 3D scanner, Swedish Hexagon CMM 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan MitutoyoRoughness Meter, etc. All this ensure that your products meet the design and functional requirements.

How to Choose Surface Finishes for CNC Car Parts

How to Choose Surface Finishes for CNC Car Parts

Hybrid Prototyping: CNC and 3D Printing

Hybrid Prototyping: CNC and 3D Printing

5 Key Points for Controlling CNC Machining Accuracy

5 Key Points for Controlling CNC Machining Accuracy

Injection moulding of medical device products|rapid cnc services

Injection moulding of medical device products|rapid cnc services