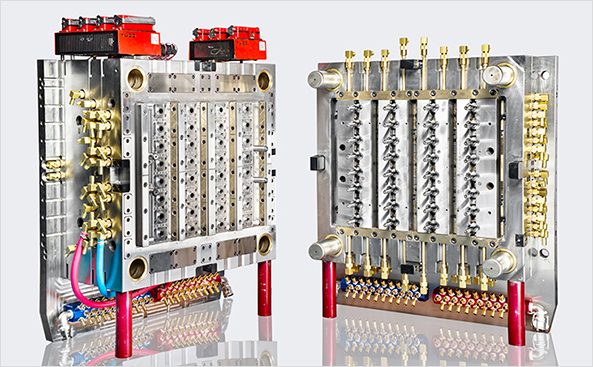

Tool making is part of Mastars vertically integrated offering, which means you can benefit from our extensive knowledge and understanding of the production and assembly process.

Mastars tooling abilitiesMastars has experienced plastic injection tooling making engineers and machinists from all over the world, who can work with you during your tool build to assist you with: > Part Design For Manufacturability (DFM)

Mastars tooling abilitiesMastars has experienced plastic injection tooling making engineers and machinists from all over the world, who can work with you during your tool build to assist you with: > Part Design For Manufacturability (DFM) How we can helpWe fully understand the impact of tolerance management on your product assembly process and ensure that the service we provide is of the highest standard. Are able to validate tools in-house using our 3D co-ordinate measuring machine.

How we can helpWe fully understand the impact of tolerance management on your product assembly process and ensure that the service we provide is of the highest standard. Are able to validate tools in-house using our 3D co-ordinate measuring machine.

Our plastic injection tooling making engineers have a full checklist they utilize for every tool design and tool build. We are able to manufacture P20 or H13 steel tools at 1/3 to 1/2 the cost of aluminum tools in the other countries.

Therefore, in an effort to better serve our customers and deliver a better product we have begun to exclusively build steel tools in global. Utilizing a more efficient system it allows us to manufacture a steel tool in the same timeframe as an aluminum tool, while providing a better finished product at a lower cost.

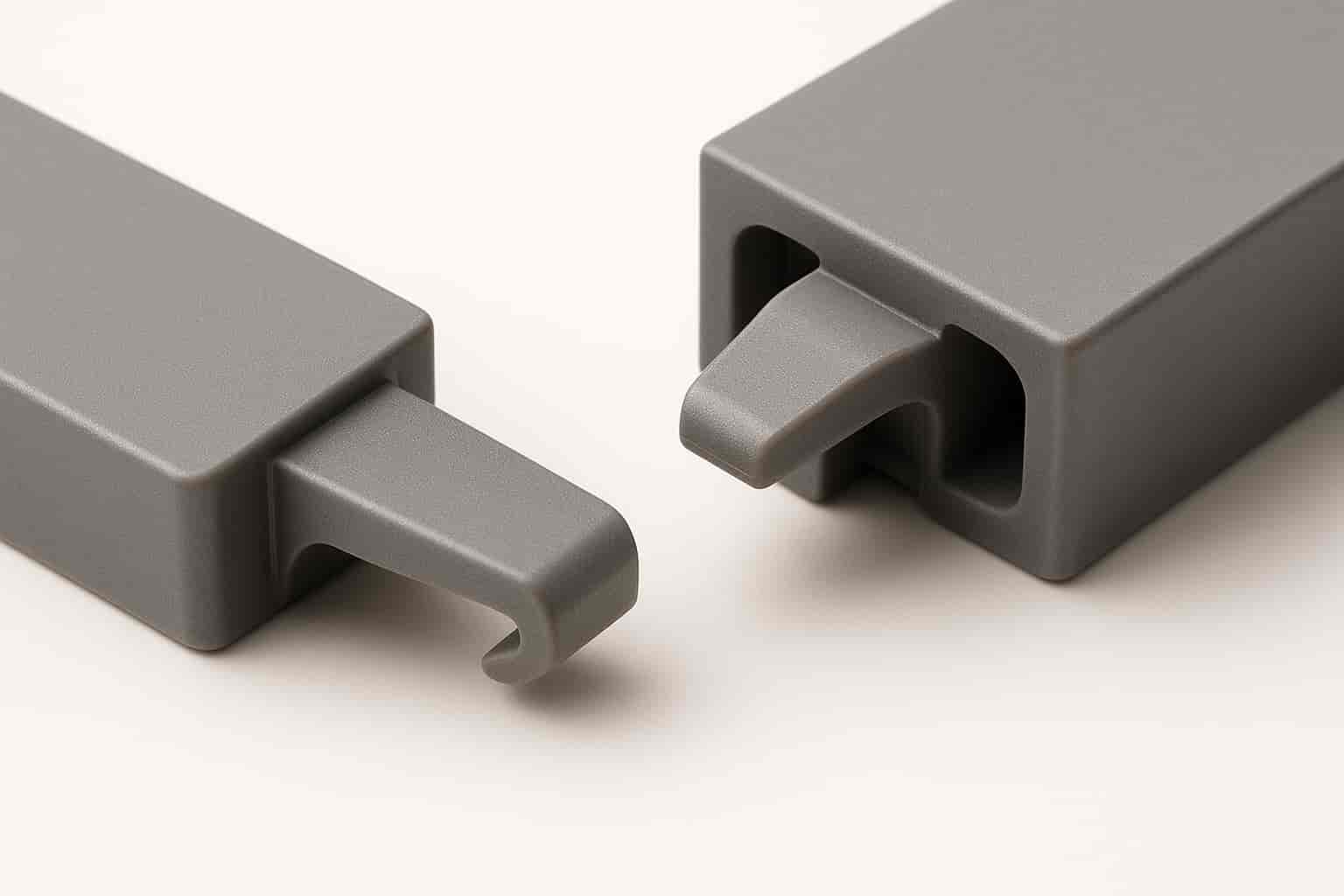

Best Practices for Injection Moulded Snap-Fit Joints

Best Practices for Injection Moulded Snap-Fit Joints

Injection Molding Common Issues & Solutions

Injection Molding Common Issues & Solutions

Future Trends in the Injection Molding Industry: Digitization and Sustainability

Future Trends in the Injection Molding Industry: Digitization and Sustainability

Injection moulding of medical device products|rapid cnc services

Injection moulding of medical device products|rapid cnc services