Supplier cybersecurity audits are critical for protecting Australian manufacturers in the Industry 4.0 era. With interconnected systems like IoT, AI, and cloud computing driving efficiency, these same technologies expose supply chains to cyber threats. Audits address vulnerabilities in supplier networks, ensuring compliance with Australian regulations and safeguarding sensitive data.

By integrating audits into Industry 4.0 processes, manufacturers protect intellectual property, maintain production continuity, and build trust with clients. Investing in cybersecurity audits is not just about compliance - it’s about securing the future of Australian manufacturing.

Manufacturing supply chains are a prime target for cyberattacks due to their interconnected networks and multiple entry points. With the rise of Industry 4.0, these connections often extend through vulnerable supplier systems, creating opportunities for cybercriminals.

One of the most destructive threats is ransomware. These attacks lock down crucial production data, demanding payment for decryption keys. Such incidents can halt operations entirely, not just for a single manufacturer but for multiple interconnected suppliers, causing widespread disruption.

Data breaches through supplier networks are another major risk. When suppliers fail to secure systems holding intellectual property, customer information, or proprietary processes, they become easy targets. This is especially concerning in sectors like medical devices, where compromised systems could expose highly sensitive data.

Supply chain poisoning is a more covert but equally damaging threat. By embedding malicious code or components via trusted suppliers, attackers can gain long-term access to production systems. These breaches often go undetected for months, enabling cybercriminals to steal trade secrets, monitor operations, or disrupt critical processes when it matters most.

The growing use of IoT devices in manufacturing further complicates security. Smart sensors and automated machinery, if not properly secured, can be exploited for botnet attacks or used as gateways for attackers to move laterally within networks. These challenges make it clear that strong audit frameworks are essential - a topic explored further in the context of Australian manufacturers.

The risks outlined above don’t just threaten IT systems - they have real-world consequences for Australian manufacturers, impacting operations, finances, and reputations. A single breach through a supplier can lead to immediate production shutdowns and lengthy recovery periods.

Financially, these incidents are costly. Beyond recovery expenses, manufacturers may face regulatory penalties under the Privacy Act 1988, as well as costs for forensic investigations, legal support, customer notifications, and credit monitoring services.

Theft of intellectual property, such as design plans or customer lists, poses a long-term competitive threat. Often, breaches go unnoticed for extended periods, giving competitors time to exploit stolen information, potentially eroding market advantages.

Non-compliance with cybersecurity regulations can lead to scrutiny from bodies like the Australian Cyber Security Centre or industry-specific regulators. This is particularly critical for manufacturers in sectors like medical devices or automotive, where compliance failures can disrupt operations and damage reputations.

Customer trust is another casualty of supplier-related breaches. If clients - especially those in sensitive areas like government or defence - perceive supply chains as insecure, manufacturers risk losing contracts or damaging long-standing business relationships.

Insurance issues add another layer of complexity. Many policies exclude coverage for supplier-related breaches or require detailed proof of due diligence in assessing supplier security. This can leave manufacturers exposed to significant financial risks.

Australian manufacturers operate under stringent cybersecurity regulations, particularly when it comes to supplier networks. The Privacy Act 1988 holds manufacturers accountable for ensuring their suppliers implement adequate security measures to protect personal information.

To meet these requirements, manufacturers often enforce compliance with established frameworks like ISO 27001, the NIST Cybersecurity Framework, and industry-specific standards. ISO 27001 offers a comprehensive approach to security management, covering everything from risk assessment to incident response. The NIST framework provides a structured methodology with its five key functions: Identify, Protect, Detect, Respond, and Recover.

For manufacturers engaged in government projects, the Australian Government Information Security Manual (ISM) outlines specific security controls. Additionally, industry-specific standards like ISO 13485 for medical devices and IATF 16949 for automotive suppliers include cybersecurity provisions tailored to their fields.

The Australian Cyber Security Centre’s Essential Eight strategies are another vital resource. These practical measures focus on preventing malware, securing systems, and ensuring that supplier environments are protected. Incorporating these strategies into supplier audits strengthens the overall security of manufacturing supply chains, reducing vulnerabilities and mitigating risks.

Supplier cybersecurity audits start by establishing clear security requirements, identifying the systems to be reviewed, and setting timelines. During this preparation phase, manufacturers ensure suppliers understand what’s expected of them.

An initial risk assessment lays the groundwork for the audit. Manufacturers assess suppliers based on various factors, such as the type of data they handle, their connection to production systems, and their role in critical manufacturing tasks. Suppliers with higher risks - like those with direct access to production networks or sensitive intellectual property - undergo more thorough evaluations compared to those with limited system access.

The documentation review phase helps pinpoint discrepancies between what’s outlined in policies and what’s actually practiced. Here, auditors review cybersecurity policies, incident response plans, and staff training records, focusing on areas that might need deeper investigation.

The on-site technical assessment goes beyond paperwork to examine the supplier's systems, networks, and security controls directly. Auditors test firewall configurations, verify access controls, and check whether security patches are up-to-date. This step often uncovers issues like misconfigured systems or outdated software that might not be obvious from documentation alone.

Continuous monitoring shifts audits from being a one-time event to an ongoing process. Manufacturers may require suppliers to provide regular updates, including vulnerability scan results and incident reports. This continuous oversight complements earlier discussions about regulatory compliance and risk management in Australian manufacturing.

The technical side of supplier audits focuses on ensuring that security measures are correctly implemented and maintained. Network security reviews check how suppliers segment their networks, particularly between production systems and general business operations. Auditors also verify the use of multi-factor authentication and updated access controls.

Data encryption and vulnerability management practices vary depending on the sensitivity of the information. Auditors ensure data is encrypted both in transit and at rest, evaluate encryption protocols, and review patch management processes. They also confirm that critical updates are applied within acceptable timeframes.

Documentation plays a key role beyond technical measures. Suppliers must keep detailed logs of system access, security incidents, and any remediation efforts. These records provide evidence that security measures are effective and help identify patterns that could signal new threats.

Backup and recovery procedures are tested to confirm that suppliers can quickly restore operations after a security incident. Auditors check that backups are performed regularly, stored securely, and can be successfully restored. Simulated recovery exercises are often part of this process to ensure these systems work under real-world conditions.

By verifying these technical controls, manufacturers can strengthen their operational security and build trust with clients.

Supplier audits play a critical role in enhancing security for Original Equipment Manufacturers (OEMs). For companies like Mastars, these audits ensure secure digital collaboration while protecting sensitive designs across the supply chain. When Mastars works with suppliers for specialised components or materials, cybersecurity audits safeguard customer designs and proprietary manufacturing processes.

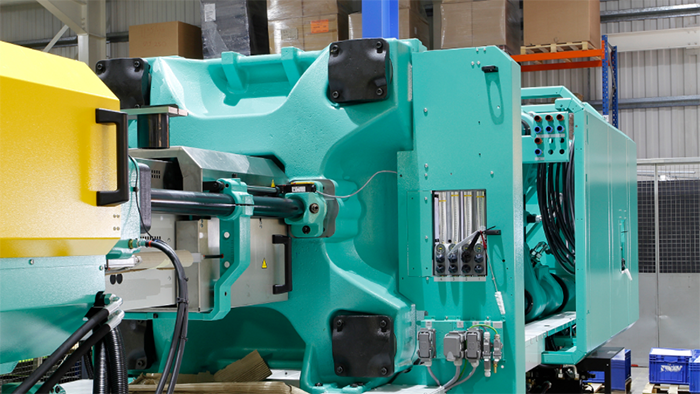

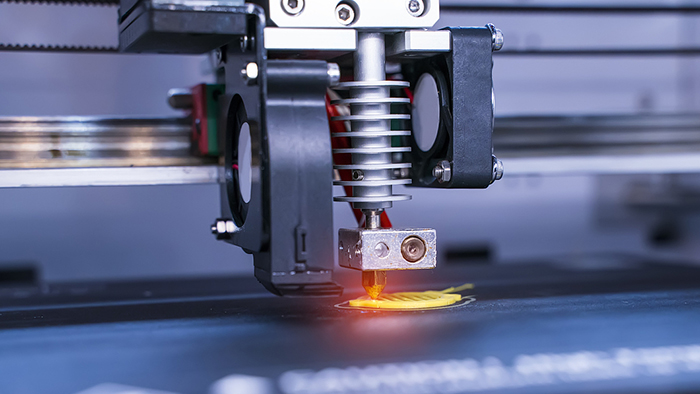

For OEMs engaged in activities like rapid CNC machining or injection moulding, secure supplier networks allow for seamless sharing of design files, production schedules, and quality control data. This reduces the need for manual data transfers, speeding up project timelines and minimising errors.

Customer confidence grows when OEMs demonstrate that their supply chain meets stringent cybersecurity standards. For clients in industries like medical devices or automotive components, knowing that suppliers undergo rigorous audits provides peace of mind that their proprietary designs and sensitive data are well-protected.

Operational resilience is another significant benefit. Cyber incidents affecting suppliers can disrupt entire production networks, leading to delays and increased costs. Audits help identify vulnerabilities early, keeping manufacturing processes running smoothly and avoiding costly interruptions.

Regulatory compliance becomes easier to manage when suppliers adhere to established cybersecurity standards. For OEMs in regulated industries, demonstrating supplier compliance with these frameworks helps meet legal requirements and reduces the risk of violations that could impact operations.

Lastly, secure supplier relationships offer a competitive edge. When suppliers have robust cybersecurity measures in place, manufacturers can confidently take on projects involving sensitive technologies or high-security applications, opening doors to new markets and revenue opportunities.

Australian manufacturers have embraced advanced tools to streamline supplier cybersecurity audits, stepping away from manual processes like spreadsheets. Automated platforms now provide real-time insights into supplier risks, making it easier to stay on top of potential vulnerabilities. For example, third-party risk management platforms continuously monitor suppliers' cybersecurity practices. They analyse publicly available data - such as IP addresses, domain setups, and security certificates - and assign security scores, much like credit ratings. This approach offers ongoing visibility without the need for constant manual checks.

Vulnerability scanning tools are another critical component. These tools help manufacturers spot outdated software, misconfigured firewalls, and unpatched security gaps in supplier systems. By automating these scans, manufacturers can significantly cut down on manual effort while still maintaining thorough risk assessments.

Compliance management software is also transforming the audit process. These programs standardise supplier questionnaires, track responses, and even flag incomplete or concerning feedback for further review. Manufacturers can customise audit templates to meet specific industry standards, ensuring a more tailored and effective compliance process.

Network monitoring solutions go a step further by continuously observing data flows between manufacturers and suppliers. These tools can detect unusual traffic patterns, which might signal a breach or unauthorised access attempt, providing a deeper layer of security.

Take manufacturers like Mastars, for example. By using these tools, they can efficiently evaluate suppliers involved in rapid prototyping and production. This ensures that sensitive customer designs remain secure throughout the supply chain, all without disrupting production timelines.

These tools set the stage for robust compliance practices, which we’ll delve into next.

Keeping supplier cybersecurity compliance up to date requires a structured approach that can adapt to evolving threats and regulations. For critical suppliers, quarterly compliance reviews are essential. These reviews focus on recent security incidents, system updates, and any changes to policies, ensuring ongoing alignment with security standards.

For manufacturers lacking extensive in-house cybersecurity expertise, managed cybersecurity services can be a game-changer. These services handle supplier monitoring, incident response, and compliance reporting, often at a lower cost than maintaining a full internal team. This makes them particularly appealing for smaller manufacturers.

Education and training also play a pivotal role. By offering cybersecurity awareness programs to supplier personnel, manufacturers can address common vulnerabilities caused by human error. Topics like phishing prevention, secure data handling, and incident reporting can significantly reduce the risk of breaches.

Incident response coordination is another key element. Manufacturers need clear communication channels for reporting security incidents, along with 24-hour contact procedures and escalation protocols. This ensures swift containment and resolution of security issues affecting suppliers.

Embedding cybersecurity requirements into supplier contracts is another effective strategy. Contracts should include clear standards, audit rights, breach notification clauses, and penalties for non-compliance. These measures make adherence enforceable and align suppliers with the latest security expectations.

Monitoring supplier security metrics over time is equally important. Automated alerts can notify manufacturers if a supplier's security rating drops below acceptable levels, prompting immediate action to address the issue.

By combining these methods, manufacturers can integrate security into their workflows without compromising efficiency.

As Australian manufacturers adopt Industry 4.0 technologies, cybersecurity audits must integrate seamlessly with these advanced systems to ensure production remains secure and uninterrupted. For instance, API security assessments are vital as manufacturers increasingly connect their systems with supplier platforms for real-time data sharing. These assessments confirm that APIs use proper authentication, encryption, and access controls.

The rise of IoT devices in manufacturing has expanded the scope of audits. Connected sensors, monitoring equipment, and other automated systems operated by suppliers must undergo regular security updates, use strong authentication, and maintain secure communication channels.

Digital twins - detailed virtual models of production processes - are another area requiring attention. When manufacturers share these models with suppliers for collaboration, audits must ensure that access controls, encryption, and data loss prevention measures are in place to protect these valuable assets.

Cloud infrastructure is another critical focus. With manufacturers and suppliers often collaborating on shared cloud platforms, audits should evaluate access controls, data segregation, and backup procedures to safeguard sensitive information in multi-tenant environments.

Real-time monitoring tools can also integrate with production systems, offering unified visibility into both operational and security metrics. This allows manufacturers to quickly identify and address security events that could disrupt production schedules.

Lastly, automated compliance reporting linked to production systems can align with project milestones, reducing administrative overhead for production teams. These integrated approaches ensure that cybersecurity measures not only enhance security but also support operational efficiency and production goals.

Thorough supplier audits play a crucial role in reducing security risks while boosting compliance with regulations and earning customer confidence. Studies indicate that manufacturers adopting such frameworks tend to see improvements across various operational and business areas.

The operational perks are clear: consistent security standards, better supplier relationships, and even reduced insurance premiums. These are particularly vital for protecting sensitive designs. For firms like Mastars, which handle confidential customer designs, audits act as a safeguard against potential breaches.

Cyber incidents can lead to major financial setbacks, including downtime, notification costs, and hefty penalties. On the other hand, proactive audit programs offer consistent protection at a fraction of the cost it would take to recover from a breach.

In industries like automotive and medical devices, customer trust is heavily tied to strong cybersecurity measures. Demonstrating a robust supplier audit program can set manufacturers apart, helping them secure lucrative contracts and build lasting partnerships.

These advantages create a foundation for ongoing security enhancements and better preparedness for future challenges.

To sustain these benefits, manufacturers must keep evolving their audit practices. Regular investment in audit capabilities is key to maintaining long-term supply chain security.

Australian manufacturers should prioritise cybersecurity within their IT budgets, with a sharp focus on managing supplier risks. Preparing for the future means embracing tools like AI-driven risk assessments, blockchain-based verification systems, and continuous staff training to adapt to changing regulatory demands. Early adoption of such technologies not only enhances security but also lowers operational costs over time.

Keeping up with regulatory changes is equally important. The Australian Cyber Security Centre frequently updates its infrastructure protection guidelines, while international standards such as ISO 27001 and NIST are expanding their frameworks. Partnering with cybersecurity experts who specialise in manufacturing compliance can further solidify a company’s security measures.

Collaboration is becoming a key strategy across the industry. Sharing threat intelligence, audit strategies, and supplier security ratings through industry associations and secure platforms can help manufacturers collectively strengthen the supply chain. This cooperative effort can lead to reduced audit costs, improved threat detection, and a more resilient manufacturing ecosystem overall.

Supplier cybersecurity audits are essential for safeguarding manufacturing supply chains, especially in the Industry 4.0 era. These audits pinpoint weaknesses in suppliers' systems and ensure they meet stringent security requirements. By addressing these gaps, the risk of cyberattacks - which are becoming more frequent in advanced manufacturing settings - can be significantly reduced.

Conducting audits on a regular basis also pushes suppliers to stay current with their security practices. This includes applying software updates and actively monitoring for potential threats. Such a proactive stance not only protects sensitive manufacturing data but also keeps operations running smoothly, reinforcing the entire supply chain's ability to withstand cyber risks.

The rise of IoT and AI technologies in Australia's manufacturing sector has introduced a fresh set of cybersecurity challenges. IoT devices, often lacking robust security measures, can create weak points within a network. Pair this with the expanded attack surfaces brought on by AI-driven automation, and the risks become even more pronounced. Add in vulnerabilities like weak passwords or unauthorised access, and the potential consequences - data theft, production delays, or even complete operational shutdowns - become very real.

One effective way to tackle these risks is through supplier audits. These audits are crucial for ensuring vendors comply with cybersecurity standards, exposing potential weak spots, and confirming secure practices. By conducting regular evaluations, manufacturers can hold third-party suppliers accountable for maintaining strong security protocols. This not only helps prevent breaches within the supply chain but also protects the integrity of interconnected systems that are vital to modern manufacturing.

Continuous monitoring plays a key role in supplier audits by spotting cybersecurity risks and unusual activities as they happen. This real-time vigilance reduces the likelihood of breaches and ensures suppliers stay aligned with industry security standards.

It also simplifies compliance checks by automating verification tasks, which helps minimise disruptions during audits. With ongoing oversight, manufacturers can protect the integrity of their operations and ensure suppliers consistently follow the necessary protocols.