What Is Thermoset Injection Molding?

Thermoset injection molding is a technique where raw thermosetting polymers are injected into a heated mold. Once inside, the material cures irreversibly through cross-linking, meaning it cannot be remelted or reshaped.

This irreversible curing makes thermosets ideal for high-performance applications requiring mechanical strength, electrical insulation, and chemical resistance. For industry context, see the Plastics Industry Association for background on thermoset materials and manufacturing trends: Plastics Industry Association.

Step-by-Step Thermoset Injection Molding Process

The thermoset injection molding process consists of several controlled steps designed to ensure consistent part quality.

- Material Preparation – Thermoset pellets or powders are preheated to ensure consistent flow into the injection unit.

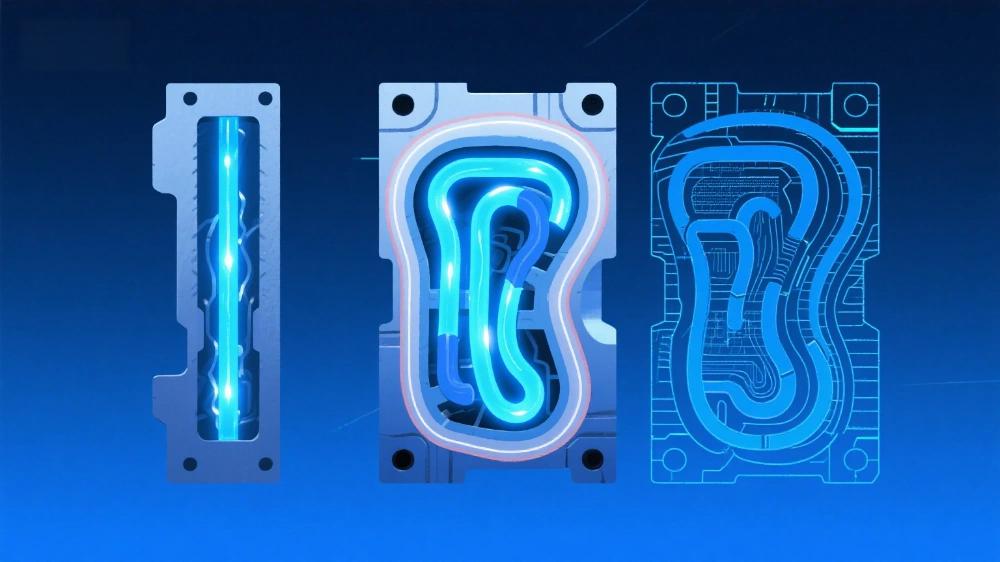

- Injection – The material is injected into the mold cavity under high pressure to fill the geometry completely.

- Curing – Heat and pressure cause the thermoset polymer to chemically cross-link and solidify permanently.

- Cooling & Ejection – Once cured, the part is cooled as necessary and ejected from the mold, ready for downstream processing.

Manufacturers offering end-to-end thermoset molding services help ensure repeatability during mass production; for example, many one-stop providers list thermoset molding among their capabilities.

Advantages of Thermoset Injection Molding

The thermoset injection molding process offers several distinct advantages for demanding applications.

- Heat Resistance – Thermoset plastics can withstand extreme temperatures without deforming, making them suitable for under-the-hood automotive components.

- Dimensional Stability – Chemical curing ensures stable part geometry even under stress and thermal cycles.

- Durability – Parts are highly resistant to wear, corrosion, and many chemical agents.

- Cost-Effectiveness – Thermoset molding can be efficient for high-volume production due to optimized cycle control.

Research and industry analyses often highlight thermoset composites as replacements for metals in weight-sensitive sectors; see related literature on materials substitution and composites research at ScienceDirect: ScienceDirect.

Thermoset vs. Thermoplastic Injection Molding

The key difference between thermoset and thermoplastic injection molding lies in material behavior after molding: thermoplastics can be reheated and reshaped, thermosets cannot. That fundamental contrast drives different use cases.

Thermoset molding is preferred for permanent, high-performance parts such as electrical connectors, automotive engine components, and medical housings. Thermoplastics dominate flexible, consumer-oriented products and packaging.

Industrial Applications of Thermoset Injection Molding

Thermoset injection molding is widely adopted across industries that demand reliability and long-term performance.

- Automotive – Engine covers, brake-system components, and other under-the-hood parts.

- Electronics – Circuit breakers, electrical switches, and insulating housings.

- Aerospace – Structural parts that require thermal resistance and weight savings.

- Medical Devices – Surgical tool handles, housings, and precision components.

Market studies and forecasts point to steady growth in thermoset plastics use driven by automotive lightweighting and advanced composites demand. For market context, consult industry reports at MarketsandMarkets: MarketsandMarkets.

Quality Control in Thermoset Injection Molding

Quality assurance in thermoset molding relies on a mix of inspection methods and material testing to verify every batch meets specifications.

Common practices include dimensional inspection to confirm tolerances, material testing to ensure proper curing behavior, and surface-finish checks to detect defects early in production.

ISO-certified manufacturers commonly integrate these checks into process control systems to reduce scrap and maintain consistent part performance.

Sustainability and Thermoset Injection Molding

Although thermoset plastics cannot be remelted into their original form, modern recycling approaches focus on grinding production scrap into fillers or using thermoset-derived materials in secondary applications.

Moreover, the durability of thermoset parts can contribute to lifecycle sustainability by reducing the frequency of replacements. Innovations in bio-based resins and advanced recycling methods are also emerging in the industry; see European Plastics Converters for related initiatives: EuPC.

Partnering With a Reliable Thermoset Injection Molding Company

Choosing the right manufacturing partner is crucial for businesses requiring thermoset injection molding. A reliable supplier should provide engineering support, prototyping, tooling, and production under consistent quality standards.

Look for partners that offer end-to-end services including tooling, surface finishing, assembly, and supply-chain support. One-stop providers often combine CNC machining, 3D printing, rapid prototyping, and injection molding capabilities to accelerate product development and reduce time-to-market.