Hydropower systems face constant challenges like erosion, corrosion, and cavitation, which can weaken equipment and lead to costly repairs. Sheet metal, with its strength and corrosion resistance, is a key material for protecting critical components like turbines, gates, and penstocks. Modern manufacturing techniques, such as CNC machining, advanced alloys, and protective coatings, further improve performance and durability, ensuring longer lifespans and reduced maintenance for hydropower infrastructure in Australia.

Mastars provides tailored sheet metal solutions for Australian hydropower plants, using cutting-edge manufacturing and quality control systems to meet industry demands.

Sheet metal plays a crucial role in hydropower systems, standing up to intense water pressure and mechanical stress. Its distinct properties and precise fabrication make it a reliable choice for these demanding conditions.

What makes sheet metal so effective in hydropower applications? Two standout qualities are its corrosion resistance and high strength-to-weight ratio. These attributes allow it to handle hydraulic pressures, simplify installation and upkeep, and endure constant exposure to water.

Additionally, sheet metal's excellent machinability supports the creation of custom components with precision. Its flexibility and formability enable it to absorb dynamic loads and vibrations, ensuring dependable performance over time.

Hydropower facilities rely on sheet metal for critical components like turbines, gates, and piping systems due to its durability and resistance to corrosion.

To further boost performance, advanced surface treatments are applied to sheet metal used in hydropower. Protective coatings and specialised alloys add extra layers of defence against corrosion and mechanical wear.

These treatments not only extend the lifespan of components but also help maintain their structural integrity over long periods. This means less maintenance and improved reliability for hydropower systems overall.

Hydropower equipment faces constant challenges that impact its performance and increase maintenance demands. To keep these systems running efficiently, it’s crucial to understand the forces that cause wear and tear and develop strategies to mitigate them using advanced sheet metal technologies.

One of the biggest culprits is erosion. Turbine runners and guide vanes are particularly vulnerable to this, as high-velocity water carrying sediment particles grinds away at their metal surfaces. This process is similar to abrasive wear and becomes even more aggressive during flood seasons, when debris levels rise, further reducing turbine efficiency over time.

Corrosion is another persistent issue. Coastal facilities are often exposed to saltwater intrusion, while freshwater locations deal with dissolved minerals that can lead to surface pitting and structural weakening.

Then there’s cavitation - a phenomenon that occurs when water pressure drops sharply around turbine blades, creating tiny bubbles that collapse with force, leading to rapid pitting. On top of that, Australian hydropower plants often experience seasonal temperature swings, which cause repeated thermal expansion. This can result in micro-cracks that compromise the integrity of components.

To address these challenges, modern sheet metal solutions are designed to tackle each of these wear factors head-on.

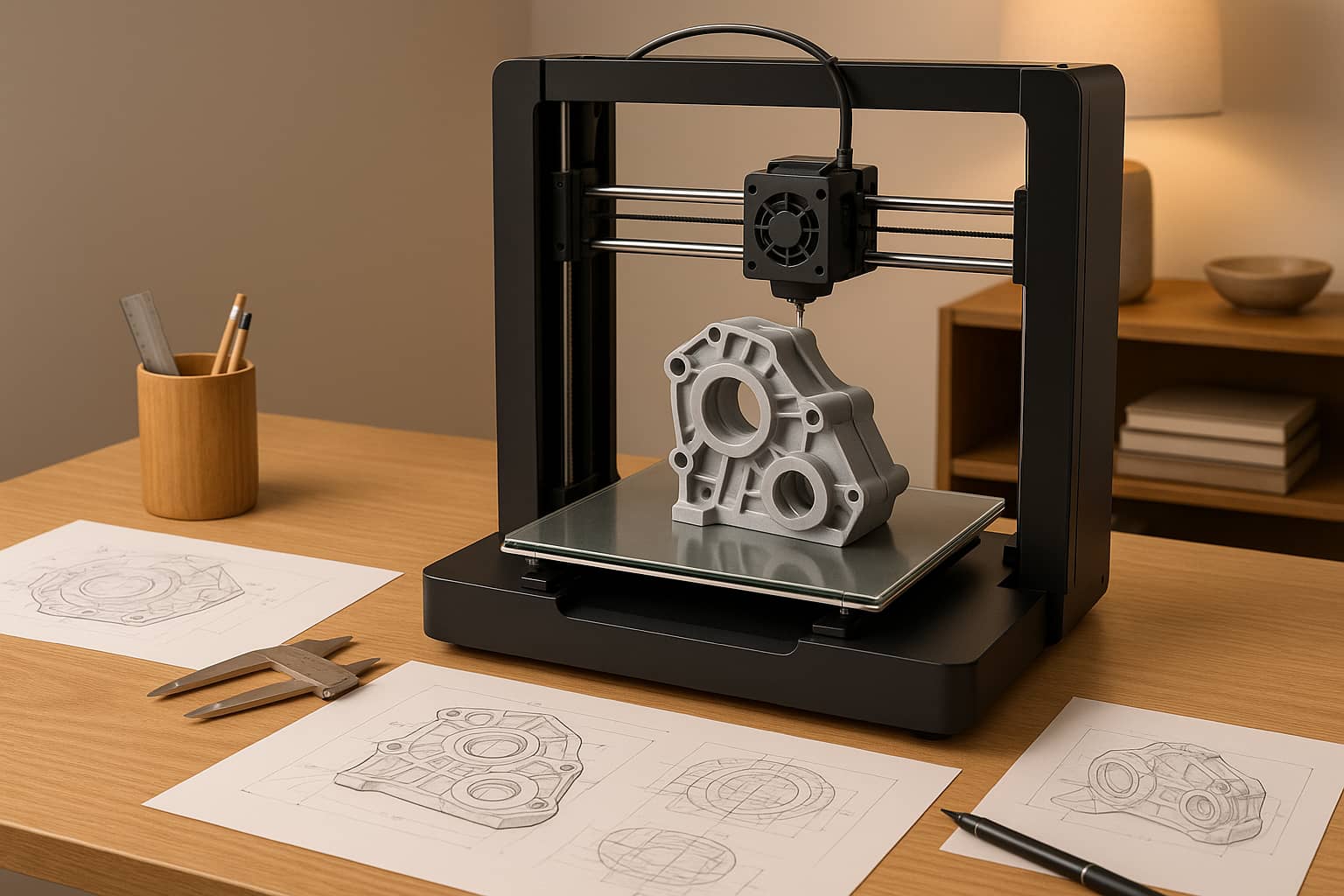

Advancements in manufacturing have brought new ways to extend the lifespan of hydropower components while cutting down on maintenance. By leveraging the benefits of advanced sheet metal techniques, companies like Mastars are helping hydropower operators stay ahead of wear and tear.

Precision CNC machining plays a big role here. This technology creates precise geometries that improve water flow and reduce cavitation. By achieving smoother surface finishes, components experience less turbulence, which in turn minimises erosive wear. Features like cooling channels and drainage systems are also incorporated to manage moisture and thermal stresses more effectively.

When it comes to combating corrosion, advanced alloys are a game-changer. Alloys containing elements like chromium, nickel, and molybdenum offer superior resistance to corrosive environments. Duplex stainless steels, with their dual-phase microstructure, provide greater strength and durability than traditional carbon steels, making them an ideal choice for hydropower applications.

Protective coatings further enhance performance by shielding the base metal from harsh environmental conditions. Thermal spray coatings and ceramic-matrix composites, for instance, create a barrier that helps prevent erosion and wear.

Another innovation is additive manufacturing, which allows for the creation of components with optimised internal features. These designs can include cooling passages and stress distribution patterns, helping to reduce weight while maintaining structural integrity under tough conditions.

Selecting the right materials for hydropower equipment is all about finding the balance between upfront costs and long-term performance. High-quality materials may require a larger initial investment, but they offer extended lifespans and reduced maintenance, ultimately saving money over time. Mastars specialises in producing these advanced components efficiently for Australian hydropower operators.

One emerging solution is composite sheet metals, which pair wear-resistant surface layers with high-strength cores. This combination delivers targeted protection exactly where it’s needed. Similarly, surface hardening treatments like nitriding and carburising create tough outer layers that boost surface durability while keeping the base material strong and resilient, significantly extending the life of components.

Choosing the right materials and technologies is critical for maintaining hydropower systems that are both reliable and efficient over the long haul. By investing in these advanced solutions, operators can ensure their equipment remains in peak condition, even under demanding conditions.

Mastars provides reliable sheet metal solutions designed specifically for hydropower applications. By using advanced manufacturing techniques, Mastars addresses the challenges of wear and tear that hydropower systems often face.

Mastars develops customised solutions for hydropower plants in Australia, using an Integrated Product Development model. This approach ensures the production of durable, high-performance components with quicker delivery times. By housing multiple manufacturing processes under one roof, Mastars simplifies the integration of components, ensuring seamless operation.

To guarantee quality and reliability, Mastars utilises cutting-edge equipment like the GOM ATOS III TRIPLE Scan Blu-ray 3D scanner, Hexagon Classic SR 7107 coordinate measuring machine, and Hitachi X-MET8000 X-ray fluorescence spectrometer. These tools verify dimensions and material composition with precision. Real-time production monitoring through their MES system ensures consistent quality, helping hydropower components resist erosion, corrosion, and cavitation. This rigorous attention to detail ensures that Mastars' solutions enable Australian hydropower systems to endure mechanical and environmental stresses effectively.

Sheet metal technology plays a crucial role in addressing the wear and tear faced by hydropower systems, helping to extend the lifespan of components and minimise downtime. By using advanced materials and manufacturing techniques, hydropower facilities can cut down on maintenance costs while boosting operational efficiency.

Materials like corrosion-resistant alloys, protective coatings, and precisely engineered components are designed to combat erosion, corrosion, and cavitation. These enhancements not only improve system reliability but also contribute to better energy efficiency, making hydropower a strong option for Australia's renewable energy ambitions. Such advancements align with the durability requirements essential for the country's clean energy future.

In practice, Mastars exemplifies these innovations through its custom designs for hydropower systems. The company employs cutting-edge techniques to create components that withstand erosion, corrosion, and cavitation, making it a trusted partner for hydropower operators aiming to maximise the reliability of their equipment.

Mastars' history of delivering durable solutions reflects its dedication to quality and performance in hydropower applications. With stringent quality control processes, including PPAP, ISIR, and PDCA, Mastars ensures that every component meets the rigorous standards demanded by the industry.

As Australia continues its push towards expanding renewable energy infrastructure, advanced sheet metal manufacturing becomes increasingly important. By collaborating with experienced manufacturers like Mastars, hydropower facilities can achieve the reliability, cost-efficiency, and performance needed to make a significant impact on the nation's clean energy goals. With state-of-the-art sheet metal solutions and tailored manufacturing approaches, the Australian hydropower sector is well-prepared for long-term success and growth.

Sheet metal plays a vital role in boosting the durability and efficiency of hydropower systems across Australia. Thanks to its strength and resistance to corrosion, it allows these systems to withstand the tough environmental conditions often encountered in hydropower operations. This not only cuts down on wear and tear but also lowers maintenance demands and extends the lifespan of critical equipment.

Moreover, high-grade sheet metal is a cornerstone in crafting essential components like turbines and penstocks. Its precise manufacturing ensures better structural stability and optimised energy performance, which leads to more dependable power generation. These advantages align seamlessly with Australia's renewable energy targets, helping to lower long-term costs while advancing a sustainable energy future.

Erosion, corrosion, and cavitation pose significant challenges to hydropower systems, leading to wear, structural damage, and a drop in efficiency. Cavitation happens when vapour bubbles form and collapse on turbine surfaces, causing material to deteriorate. Corrosion, meanwhile, stems from chemical reactions in water - especially in environments with heavy sediment - accelerating damage to vital components.

Specialised sheet metal solutions, like advanced coatings and tough surface treatments, play a key role in addressing these problems. These protective measures shield metal surfaces from harsh conditions, reducing the impact of cavitation and corrosion. As a result, hydropower equipment remains dependable and efficient over time. These advancements not only enhance the durability of hydropower systems but also support their role as a reliable option for sustainable energy production.

Advanced manufacturing methods like CNC machining play a crucial role in producing highly precise and durable sheet metal components for hydropower systems. These techniques allow for the creation of intricate parts, such as turbine housings and shafts, with remarkable precision. The result? Smoother system performance and longer equipment lifespan.

On top of that, protective coatings add another layer of resilience by safeguarding components against common hydropower issues like corrosion, erosion, and cavitation. These coatings help reduce wear and tear, cutting down on maintenance expenses while boosting the efficiency and reliability of the systems over time.

Mastars, a recognised name in manufacturing solutions, utilises advanced processes such as CNC machining and sheet metal prototyping to meet the rigorous demands of the hydropower sector. Their approach ensures high-quality, cost-efficient solutions designed for optimal performance and durability.