In the fast-paced world of manufacturing, staying ahead means embracing technologies that blend precision with flexibility. Enter metal 3D printing services—a solution that's quickly becoming a go-to for businesses tired of the limitations of traditional methods. Let's dive into why this technology is reshaping how we build everything from tiny components to industrial parts.

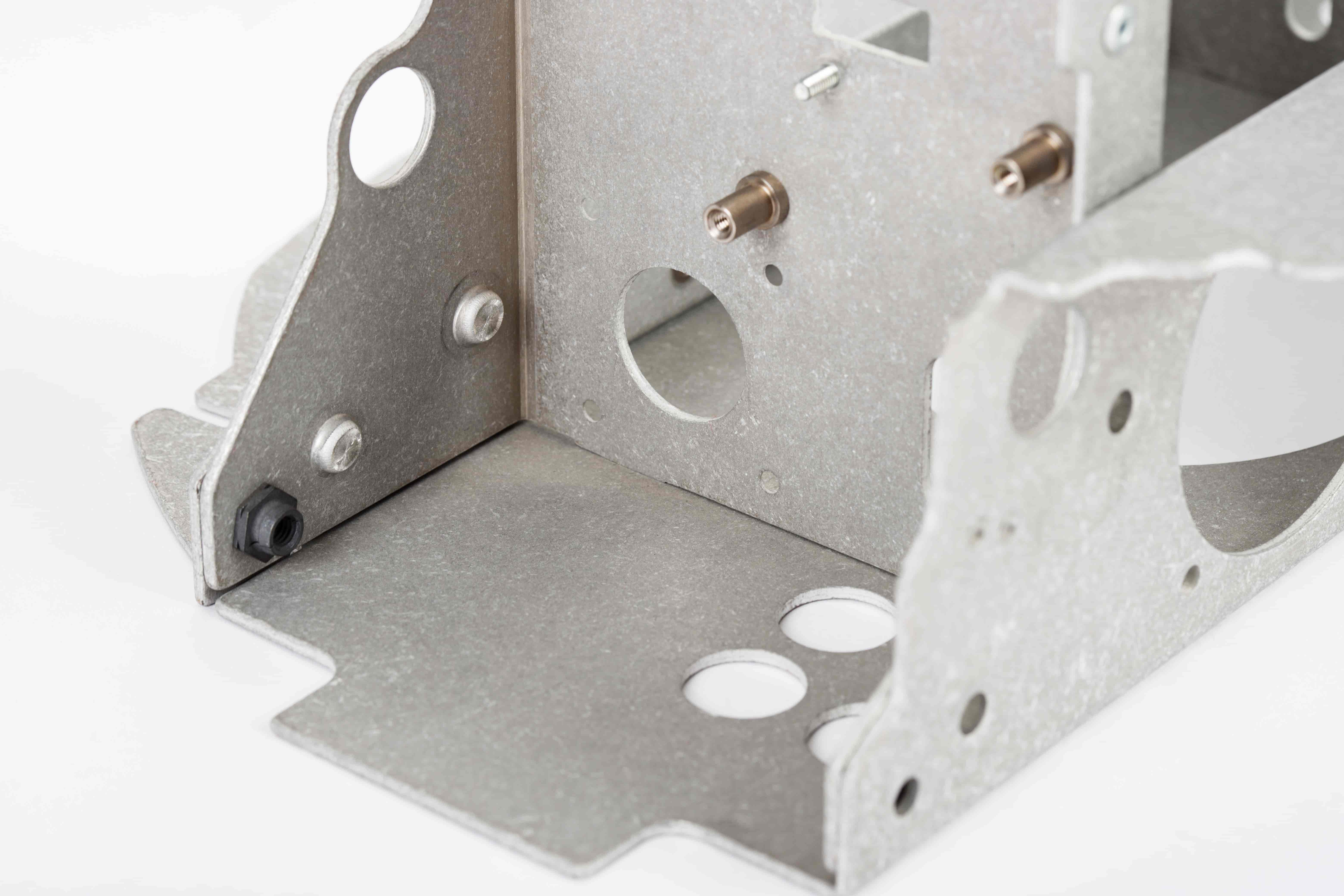

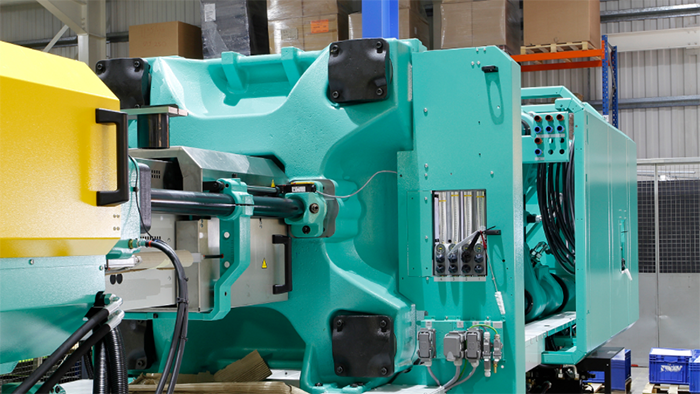

For decades, CNC machining has been the backbone of high-precision manufacturing. It's reliable, proven, and great for producing symmetrical, straightforward parts. But here's the catch: when designs get complex—think intricate lattices or internal channels—CNC can hit a wall. Tooling becomes expensive, lead times stretch, and material waste piles up. That's where metal 3D printing steps in.

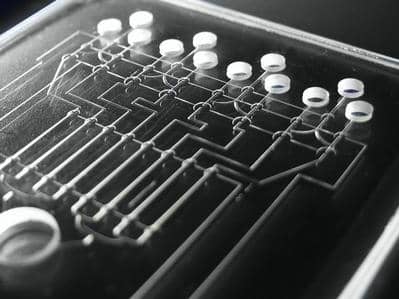

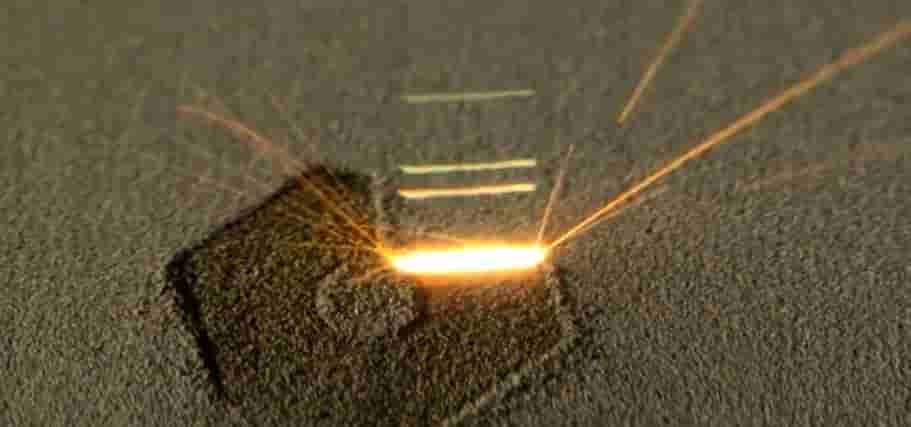

Metal 3D printing, or additive manufacturing, builds parts layer by layer using metal powders (like titanium, stainless steel, or Inconel) and high-powered lasers. This approach eliminates many of CNC's constraints. Suddenly, geometries that once seemed impossible—say, a lightweight aerospace bracket with internal cooling ducts—are not just feasible, but cost-effective.

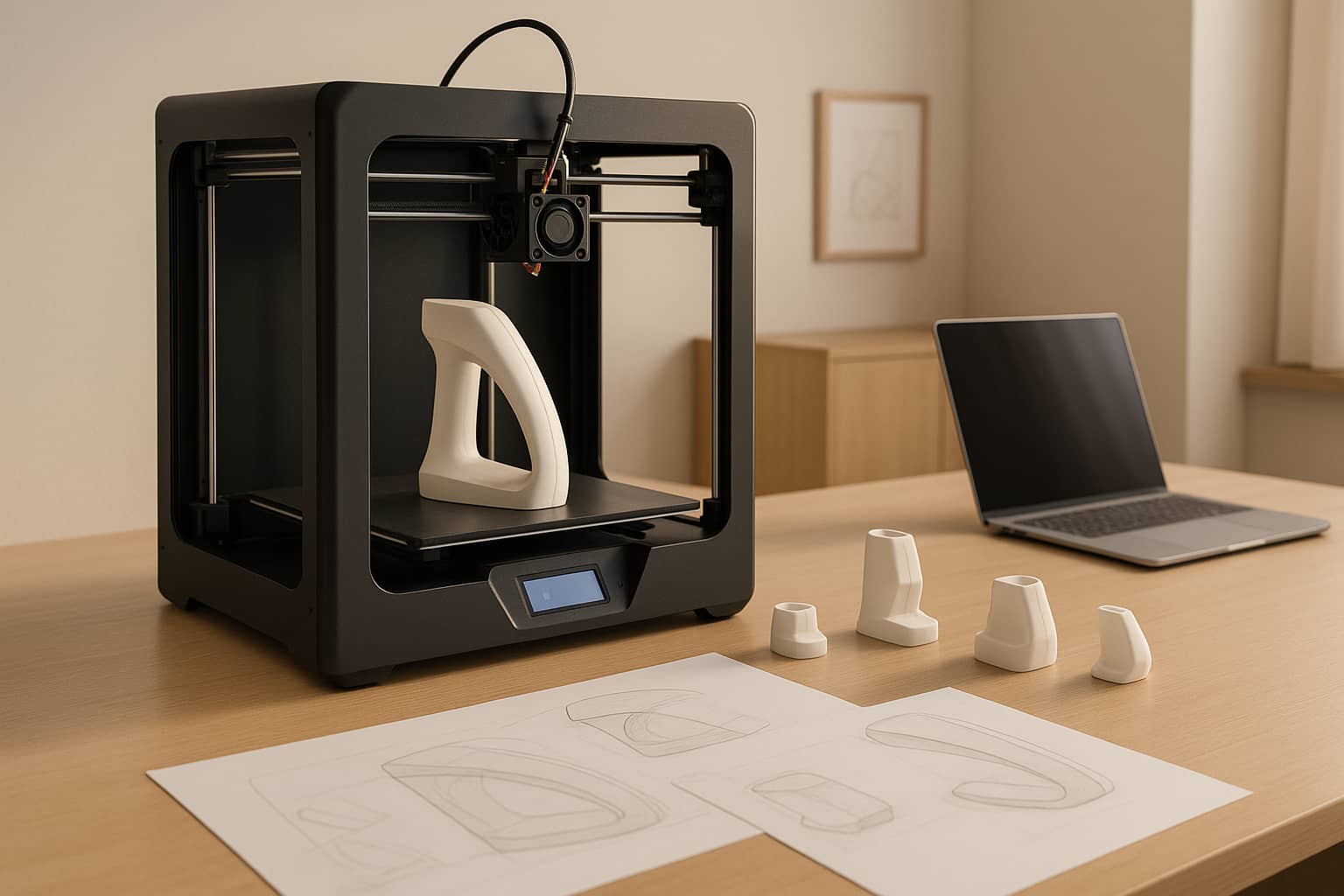

One of the biggest wins? Rapid prototyping. In the past, creating a prototype meant waiting weeks for CNC shops to set up tooling. With metal 3D printing services, you can go from a digital design to a functional metal prototype in days.

Precision is where metal 3D printing truly shines. Top-tier services achieve tolerances as tight as ±0.01mm—on par with high-end CNC machines. This makes them ideal for industries like medical device manufacturing, where a misfit implant or surgical tool can have serious consequences.

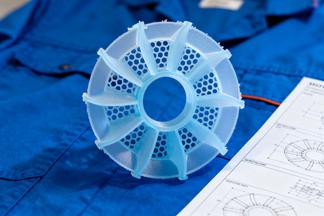

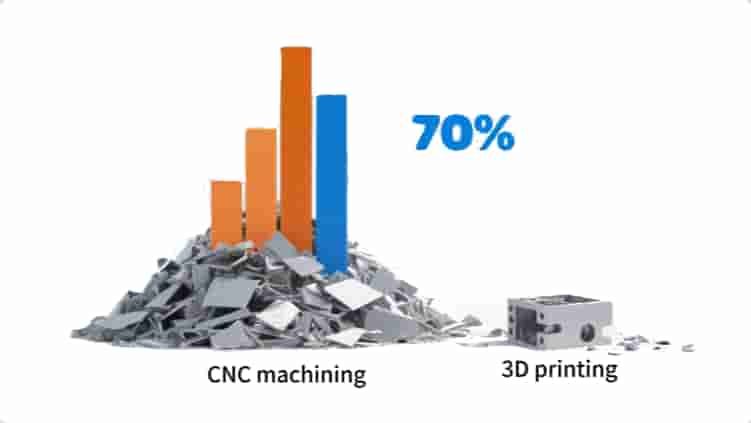

Another key advantage is material efficiency. Traditional subtractive methods like CNC start with a solid block and cut away excess—often wasting 70% or more of the material. Metal 3D printing uses only what's needed, making it a greener choice and reducing costs for expensive alloys.

In the automotive sector, race teams use metal 3D printing to create lightweight, high-strength parts. In aerospace, companies rely on it to produce turbine parts with intricate cooling systems. Medical device manufacturers use it for custom implants and surgical tools.