In manufacturing, standardised modular components are transforming how products are designed and built. Instead of creating custom parts for every product, manufacturers now use pre-made, interchangeable components. These parts simplify production, reduce costs, and allow for quicker product variations. Key benefits include:

Applications span industries such as automotive, medical devices, and consumer goods. For example, car manufacturers use standardised modules for wiring systems and brackets, while appliance makers rely on modular motor and control systems. Tools like CAD software and Design for Manufacture and Assembly (DFMA) ensure these components integrate seamlessly.

Takeaway: Modular design is reshaping manufacturing by improving efficiency, consistency, and adaptability. Australian companies adopting this approach can better compete in global markets.

Standardised modular components play a crucial role in maintaining high-quality standards and consistency in manufacturing by implementing strict controls throughout production.

By applying stringent process controls from the initial design stage to full-scale production, manufacturers can achieve consistent component quality across the board. Well-established industry practices like PPAP (Production Part Approval Process) and ISIR (Initial Sample Inspection Report) further strengthen the reliability of these systems. These quality assurance measures set the foundation for additional advantages in modular manufacturing.

The use of standardised modular components has made a noticeable impact across Australia's key manufacturing sectors. By adopting modularity, these industries enhance efficiency and maintain high-quality standards through streamlined processes. Let’s dive into how modular components are shaping the automotive, medical, and consumer goods sectors.

In Australia’s automotive industry, modular components are revolutionising production lines by improving flexibility and efficiency. Manufacturers rely on modular designs to simplify assembly processes, cutting down changeover times and boosting overall productivity.

For example, standardised connector modules replace complex, unique wiring systems. This not only reduces inventory challenges but also allows for customisation to suit different trim levels or market-specific requirements. Similarly, standardised subsystems, such as engine mounting brackets, enable the integration of multiple powertrain options without requiring a complete redesign of the chassis. This approach ensures manufacturers can cater to diverse market demands while keeping development costs in check.

Beyond passenger vehicles, modular designs are also applied to specialised machinery, such as emergency services vehicles, mining equipment, and agricultural machinery. These designs provide customisation while maintaining reliability and ease of maintenance - key factors for these demanding applications.

In the medical device sector, where precision and regulatory compliance are paramount, modular components play a critical role in ensuring consistent quality. With tolerances often measured in micrometres, this industry benefits significantly from the precision modularity offers.

Take surgical instruments, for instance. Standardised handles paired with interchangeable tool heads allow manufacturers to create extensive product ranges while ensuring consistent ergonomics and sterilisation. This approach simplifies regulatory approvals since validated base components can be used across multiple product lines.

Modular design also makes it easier to manage compliance with Australia’s Therapeutic Goods Administration (TGA) requirements. Individual components can be tested and certified independently, which means design updates can focus on specific modules without disrupting overall certifications. This flexibility proved invaluable during the COVID?19 pandemic, when Australian manufacturers quickly adapted their modular systems to produce ventilator components and personal protective equipment, showcasing the strategic benefits of modular production during emergencies.

In the consumer goods sector, modular systems are key to speeding up prototyping and reducing development timelines. For example, kitchen appliance manufacturers often use standardised motor modules, control panels, and housing components. These can be combined in various ways to create different products, ensuring consistent performance while shortening time to market.

Scalability is another significant advantage. Manufacturers can start with basic modular configurations and later introduce advanced features by swapping or adding specific modules. This approach is particularly effective for addressing seasonal demand changes or evolving consumer preferences.

The rise of smart home technology highlights how modularity drives innovation in household appliances. By integrating standardised communication modules, manufacturers can add connected features without overhauling entire product lines. This allows Australian companies to stay competitive in the fast-growing Internet of Things market while keeping production costs manageable.

Partners like Mastars play a crucial role in supporting these industries. By providing rapid CNC machining, 3D printing, injection moulding, and assembly services, they help manufacturers implement modular strategies efficiently, ensuring high quality and cost-effectiveness across automotive, medical, and consumer electronics markets.

Integrating standardised modular components effectively hinges on thorough planning and a strong commitment to quality throughout the design and manufacturing stages. It's crucial to outline compatibility requirements early on and ensure smooth integration during production. This approach builds on earlier modular concepts by prioritising seamless assembly and operation.

The principles of Design for Manufacture and Assembly (DFMA) are essential for successful modular integration. DFMA focuses on creating designs that are easy to manufacture and assemble, reducing the need for specialised tools or highly skilled labour. At its core, it supports compatibility between components, simplifying the production process.

When applying DFMA to modular systems, components are often designed to snap together or use simple fastening techniques. This not only speeds up assembly but also reduces the chances of errors. To ensure seamless integration, all modules should have well-defined physical, logical, and geometrical interfaces. For example, standardising component dimensions can make interchangeability much more straightforward.

The best modular designs minimise interdependencies between modules. By allowing each module to function independently while still contributing to the system's overall performance, assembly becomes more efficient and less prone to bottlenecks.

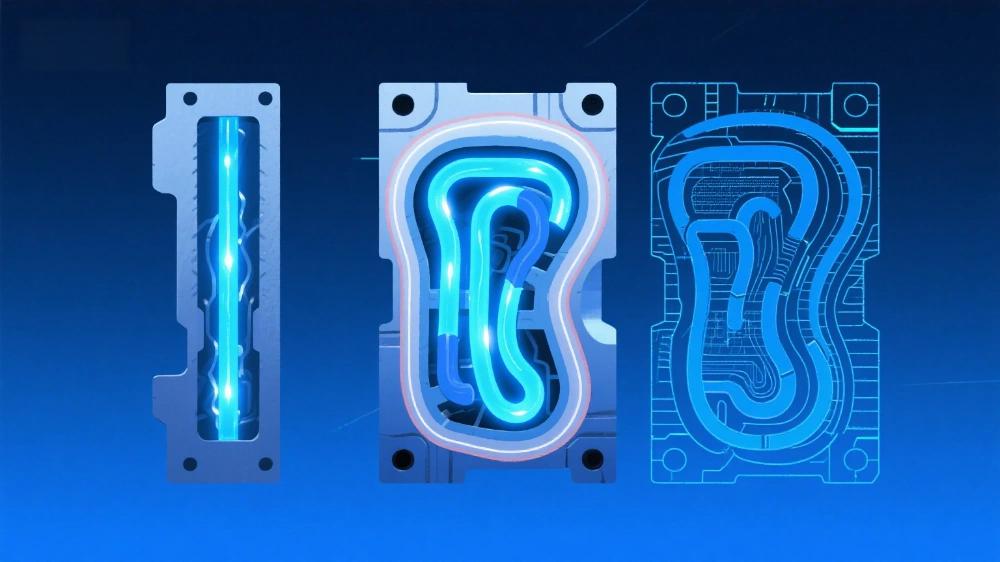

Digital tools have revolutionised how manufacturers approach modular integration. With CAD software, engineers can test component compatibility virtually, eliminating the need for multiple physical prototypes and saving both time and resources.

One particularly useful tool is tolerance stack-up analysis. This method calculates how small dimensional variations across multiple components can accumulate, potentially causing assembly issues. By addressing these variations during the design phase, manufacturers can ensure that modules fit and function correctly, even when tight tolerances are required.

Simulation software also plays a key role, allowing engineers to model how modules interact within the system. These simulations help identify potential failure points and refine interfaces before production begins. Additionally, configuration rules can be embedded into digital design systems, ensuring that modules combine as intended and align with customer requirements while adhering to business constraints.

Long-term success with modular systems depends heavily on maintaining rigorous compatibility standards. For instance, verifying material compatibility is essential to avoid issues like corrosion or degradation when different components interact. Similarly, managing dimensional tolerances across the supply chain ensures that parts produced at different times or by different suppliers integrate without problems.

Quality control should extend beyond individual components to include testing at the system level. Prototyping and functional testing of entire subsystems can uncover integration issues early, making them easier and more cost-effective to address before full-scale production.

Standardising interfaces is another critical step. This involves specifying physical connections, communication protocols, and power requirements in detail. Sharing these standards with everyone involved - suppliers, assembly teams, and quality control personnel - helps maintain consistency and ensures smooth integration.

To keep compatibility at the forefront, it’s useful to establish modular design guidelines. These guidelines should emphasise standardisation, modularity, and interchangeability, providing clear instructions on preferred connection methods, standard component sizes, and approved materials. Regular interoperability testing is also vital. By continuously verifying that components from different batches or suppliers fit and function as expected, manufacturers can avoid compatibility issues as processes or suppliers evolve.

Mastars showcases how expert manufacturing can seamlessly integrate standardised modular components. Partnering with an OEM that consistently delivers precise and reliable modular parts is key to achieving success. Here's a closer look at how Mastars' expertise supports outstanding modular manufacturing.

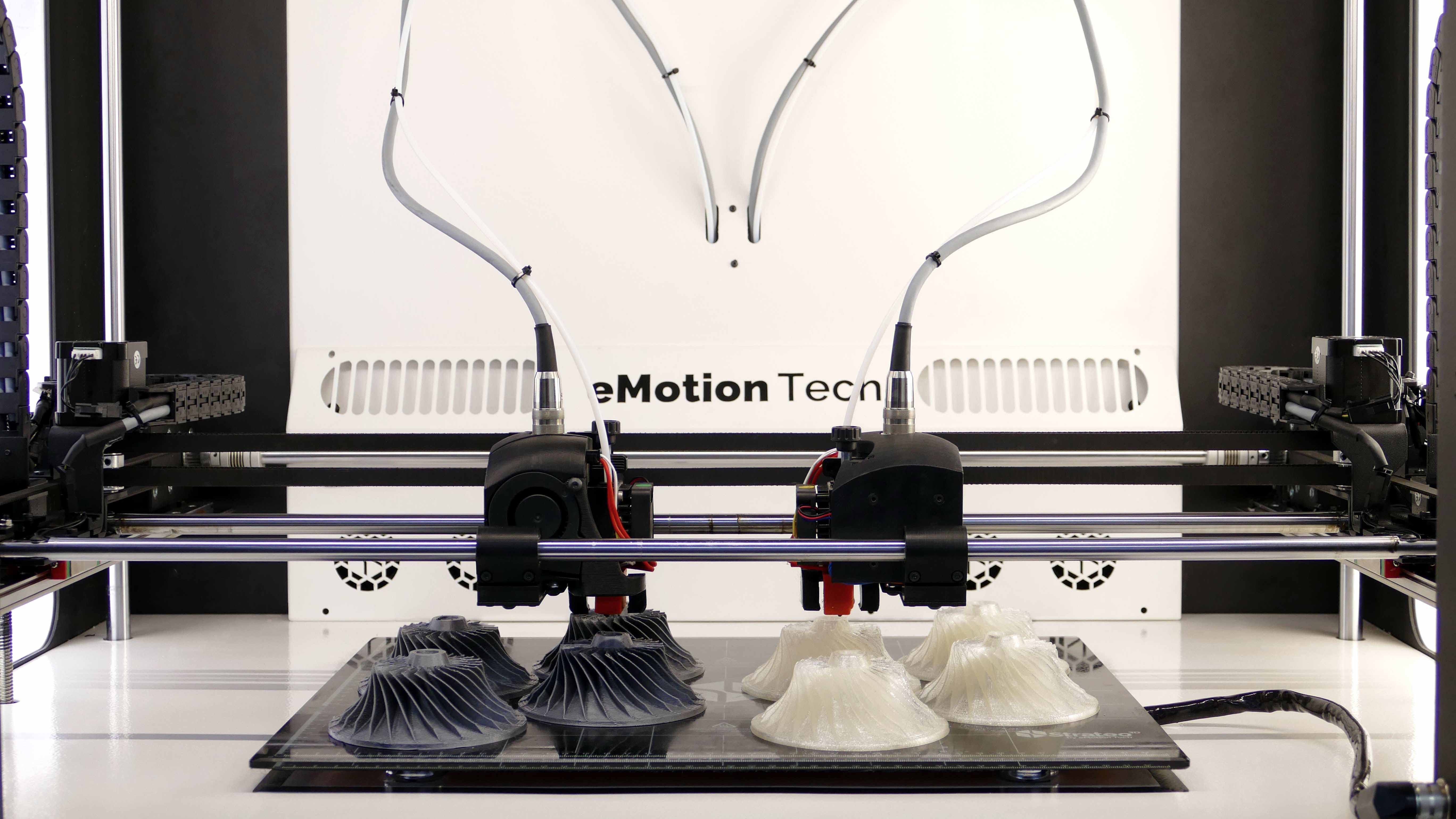

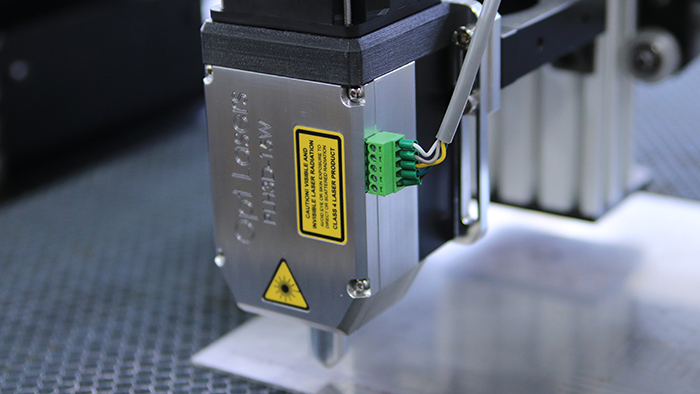

Mastars offers end-to-end manufacturing solutions, guiding modular component development from initial concept to full-scale production. Their rapid CNC machining and 3D printing services enable accurate prototyping and quick adjustments, aligning with Design for Manufacturing and Assembly (DFMA) principles while cutting down lead times.

These capabilities are particularly useful for creating modular housings and structural components that must fit precisely with other system modules, ensuring smooth integration.

When it's time to transition from prototyping to production, Mastars relies on injection moulding and pressure die casting to deliver consistent, precision-engineered components. This level of uniformity is critical for modular systems, where even minor inconsistencies can disrupt the interchangeability that modular designs depend on.

Mastars' advanced manufacturing processes cater to a variety of industries where modular designs bring considerable advantages:

Modular manufacturing thrives on precision, quick turnarounds, and cost control. Mastars employs advanced Industry 4.0 technologies to maintain rigorous quality control, speed up production, and deliver modular components that are both reliable and cost-effective.

In modular systems, even small variations in components can have a ripple effect on the entire assembly. Mastars' focus on quality ensures that every piece fits perfectly, keeping the whole system running smoothly and efficiently.

The move towards standardised modular components is revolutionising machine design and production for Australian manufacturers. By embracing modularity, companies are unlocking new levels of efficiency, cost management, and adaptability - key ingredients for staying competitive in a fast-changing market.

The benefits are clear: lower inventory requirements, simplified maintenance, quicker assembly, and the ability to reconfigure systems with ease. Consistency across modules also enhances overall product quality, ensuring reliability and customer satisfaction.

Real-world applications highlight just how adaptable modularity can be. In the automotive sector, modular electronic housings allow for seamless adjustments to different vehicle models. Medical device manufacturers achieve production efficiency while adhering to strict regulatory standards through modular designs. Even household appliance makers are using modular strategies to balance cost pressures with the need for dependable products. These examples show that success lies in precise integration, where every module fits and functions as intended.

Achieving this precision requires a focus on Design for Manufacturing and Assembly (DFMA) principles. Using digital simulations and rigorous quality control ensures that each module meets exact specifications. Even minor inconsistencies can disrupt entire systems, making attention to detail critical.

For Australian manufacturers, partnering with specialists who understand modular systems is essential. These partnerships can help navigate the complexities of modular design, ensuring flawless production and consistency across all components.

As demand grows for customisation and shorter product lifecycles, modular components offer a practical solution. Companies that adopt modular strategies now will be better equipped to respond to future market shifts, all while maintaining the quality and cost efficiency that define Australian manufacturing.

The question isn't whether to adopt modular design principles, but how quickly to implement them. Those who act decisively will gain a lasting edge in their industries, positioning themselves as leaders in this evolving manufacturing landscape.

Standardised modular components bring a big win for manufacturers looking to cut costs. By allowing bulk purchases of identical parts, companies can lower material expenses and reduce waste. Plus, these components streamline production processes, making automation and logistics more efficient. The result? Savings in both time and labour.

What’s more, standardised components speed up assembly, simplify maintenance, and reduce the need for a wide variety of parts. All of this adds up to a smarter, more economical way to manufacture products.

Design for Manufacture and Assembly (DFMA) is all about simplifying product designs to make manufacturing and assembly as smooth and efficient as possible. By cutting down on complexity, reducing the number of components, and trimming costs, DFMA ensures that modular parts fit easily into machine designs.

This method doesn’t just save time - it also helps to minimise errors and boost production speed. With DFMA in play, manufacturers can deliver higher-quality results, avoid repeated redesigns, and ensure a more straightforward journey to creating dependable, cost-efficient solutions. Industries like automotive, medical devices, and household appliances have particularly benefited from this approach.

Modular design is helping Australian manufacturers maintain a competitive edge globally by boosting efficiency, cutting production costs, and staying flexible to shifting market needs. Through the use of standardised modular components, companies can speed up product development, reduce the need for excessive inventory, and scale production effortlessly.

This method also promotes smarter use of resources and simplifies assembly processes, allowing businesses to hit tight deadlines while upholding top-notch quality. It's especially beneficial in industries like automotive, medical devices, and household appliances, where accuracy and cost management are critical.