Predictive analytics is transforming CNC machining by using data and machine learning to predict issues, optimise processes, and improve efficiency. Here's how:

Predictive analytics is helping manufacturers like Mastars deliver reliable, high-quality results across small prototypes and large-scale production, while staying on schedule and cutting costs. It’s a smarter way to meet modern manufacturing demands.

CNC machining has reached new levels of precision by tapping into real-time data and predictive analytics. These advancements help manufacturers spot potential issues before they affect quality, ensuring smoother operations and fewer errors.

Real-time monitoring has revolutionised how manufacturers maintain precision. By keeping a close eye on crucial metrics like spindle speed, feed rate, and clamp pressure, systems ensure processes stay within their specified tolerances. If cutting parameters stray from their optimal range or if actual positions don’t match the commanded ones, predictive systems immediately flag these deviations. Vibration data collected across the X, Y, and Z axes can expose early signs of mechanical problems, while unexpected temperature changes may hint at issues with cutting tools or workpiece materials. This constant tracking extends to tool health, enabling a seamless approach to precision management.

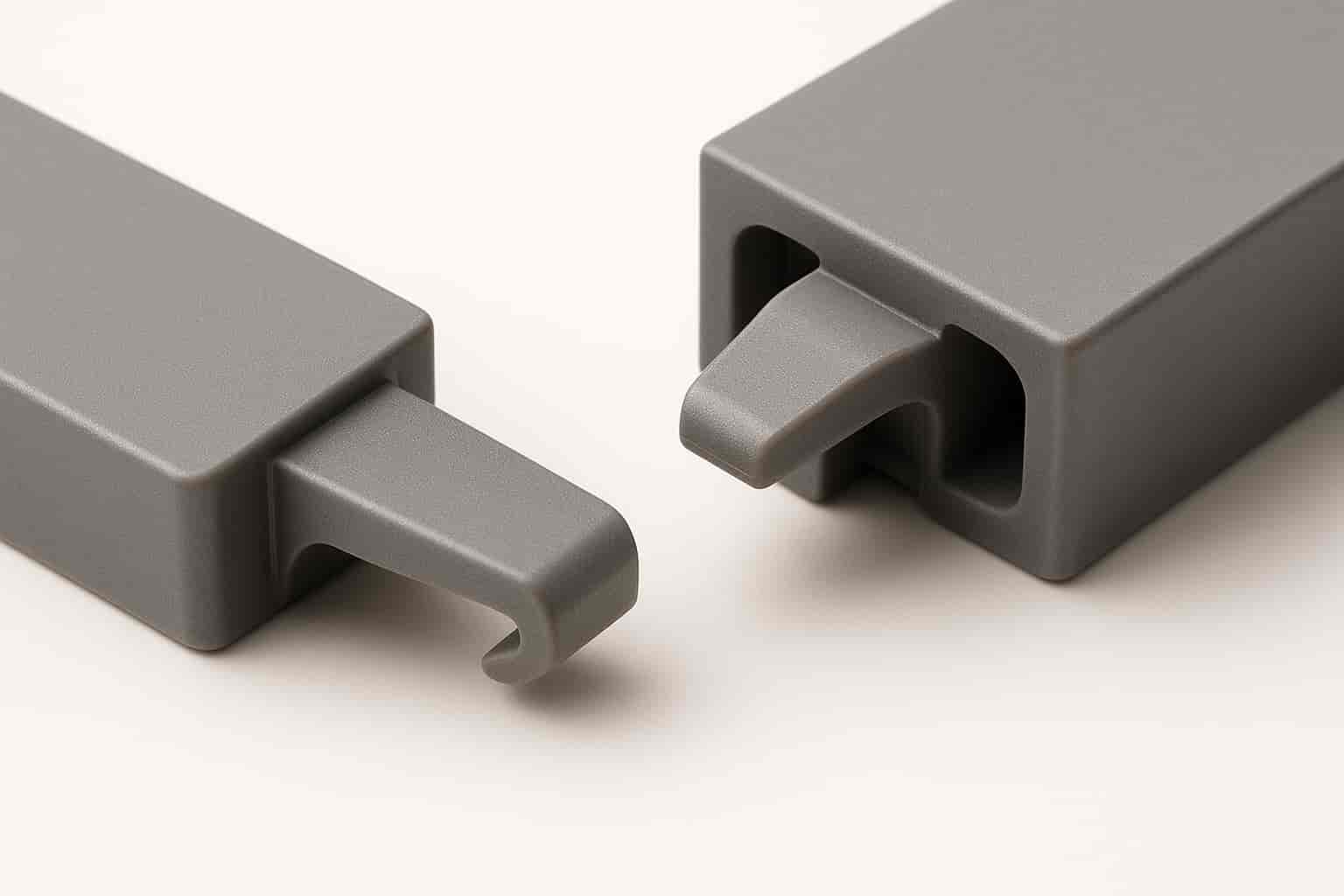

Tool wear is one of the leading causes of defects in CNC machining. While traditional methods rely on set tool-change intervals or visual checks, predictive analytics offers a smarter alternative through continuous monitoring. By predicting when a tool needs replacing, manufacturers can maintain high-quality output without unnecessary downtime. Tool wear metrics also improve the accuracy of visual inspections, ensuring tools are used efficiently and defective parts are avoided. For companies like Mastars, which manage everything from rapid prototyping to large-scale production, this predictive approach guarantees consistent quality across a range of materials and designs. It’s a game-changer for balancing cost efficiency and reliability.

When machines fail unexpectedly, production can come to an abrupt stop, piling up costs and causing delays. Predictive analytics is changing the game for CNC operations by moving from reactive fixes to proactive prevention. This shift not only cuts downtime but also slashes emergency repair expenses.

Predictive maintenance leverages IoT sensors and machine learning to keep an eye on equipment health and anticipate potential failures. These systems analyse real-time data to identify when service is genuinely needed. For CNC machines, this means tracking critical parameters to catch early warning signs of trouble. Using advanced algorithms, these systems learn the specific operating patterns of each machine, reducing false alarms while pinpointing real issues. For instance, noticing trends like rising spindle temperatures or unusual vibration changes allows maintenance to be scheduled during planned downtimes, avoiding disruptions during peak production. This approach helps create a maintenance strategy that’s both efficient and cost-effective.

Condition-based maintenance takes predictive insights a step further, focusing on servicing components based on their actual condition rather than sticking to a fixed schedule. This method avoids unnecessary part replacements and reduces labour costs, while also cutting down on emergency repairs. By aligning maintenance activities with production breaks, manufacturers can better plan operations and minimise unexpected downtime. The result? More reliable machines, improved production capacity, and predictable lead times. This reliability not only boosts customer satisfaction but also frees up production teams to concentrate on refining processes instead of dealing with constant crises.

Predictive analytics is reshaping how manufacturers approach production schedules by providing clear, data-driven insights into machine performance and process requirements. By replacing guesswork with real-time data, it creates a more efficient, reliable foundation for production planning.

Traditional production scheduling often relies on rough estimates, leading to delays and misallocated resources. Predictive analytics solves this issue by offering precise forecasts for machining times and resource requirements. For instance, studies reveal that conventional CAM software predictions for 5-axis simultaneous machining can deviate by as much as 8–74%, significantly impacting production efficiency.

"Accurate prediction of machining processing times is a critical factor in optimising production planning, as deviations in predictions made by CAM software range between 8-74% for 5-axis simultaneous machining." - ScienceDirect

Advanced predictive models, like the grey box approach that combines AI with kinematical data, deliver processing time forecasts with over 98% accuracy. This level of precision allows production managers to create schedules that align closely with actual machine capabilities and demand patterns. The result? Lower inventory costs, fewer delays, and improved delivery timelines.

Predictive analytics not only enhances scheduling but also strengthens rapid prototyping workflows, where speed and accuracy are paramount. With precise processing time predictions and early identification of bottlenecks, manufacturers can set realistic delivery dates and meet tight deadlines. This approach also ensures timely component replacement, minimising delays caused by unexpected equipment failures.

"This innovation directly contributes to speeding up manufacturing by enabling data-driven, adaptive production planning, thereby optimising resource allocation and enhancing overall operational efficiency." - ScienceDirect

Take Mastars, a company specialising in rapid CNC machining and prototyping services. By integrating predictive analytics, they can provide more accurate project timelines, boosting customer satisfaction. When paired with predictive maintenance - which schedules repairs during planned downtime - manufacturers can reduce unplanned downtime by 30% and cut on-site repair times by up to 75%. Predictive analytics also offers the flexibility to adjust production plans quickly, accommodating changing customer needs or rush orders without disrupting existing workflows.

Predictive analytics is reshaping CNC machining, turning it into a proactive, data-driven process rather than a reactive one. By addressing key manufacturing challenges, it’s helping to refine precision, improve efficiency, and ensure reliable production.

With real-time data analysis and continuous monitoring of tools, machining accuracy reaches new levels, while defects are minimised. Plus, predictive maintenance and reduced uncertainty lead to cost savings across the board.

By integrating advanced predictive models, manufacturers can better align production schedules with machine capabilities and customer needs, cutting down on scheduling variabilities and ensuring smoother operations.

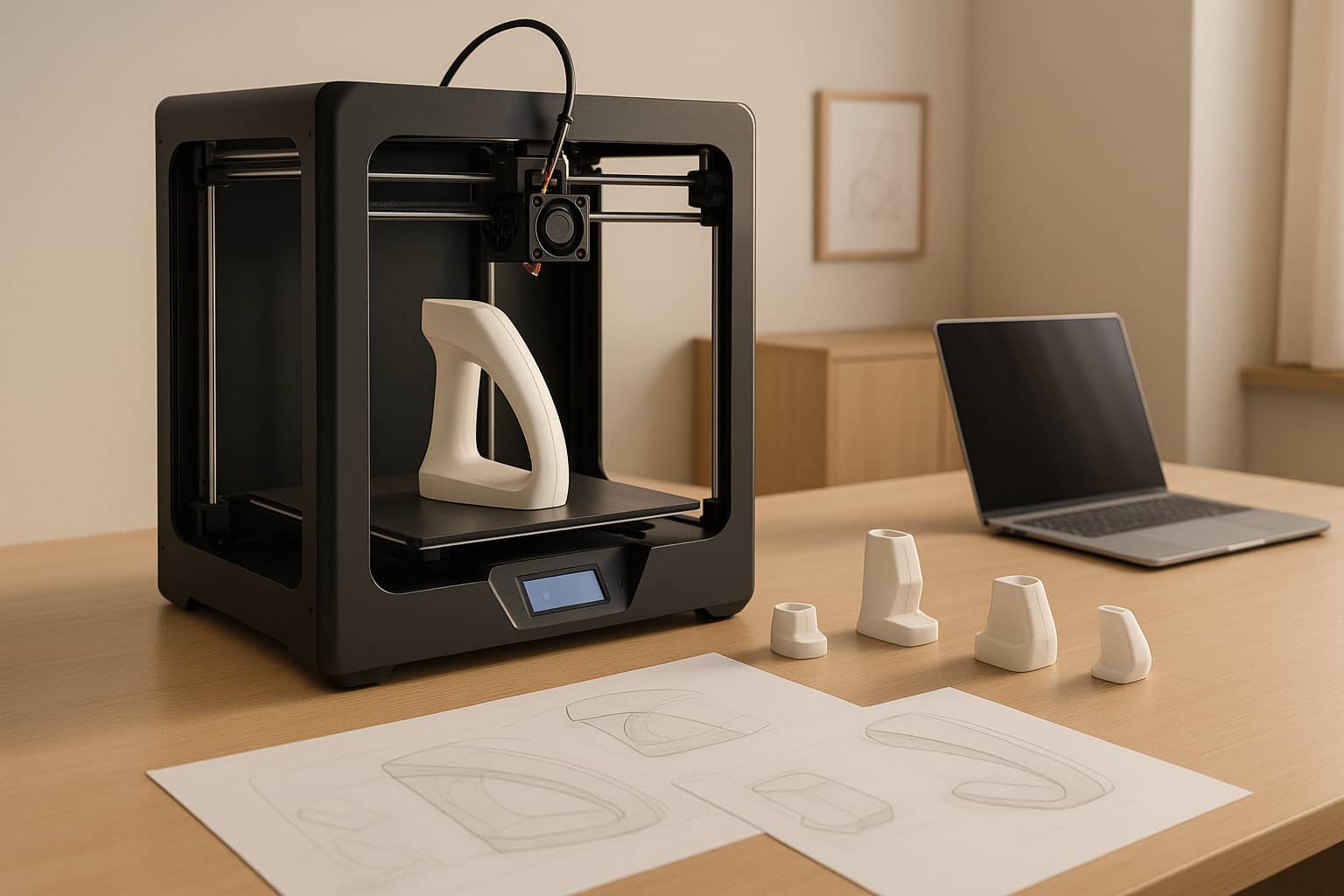

For companies like Mastars - known for their expertise in rapid CNC machining, 3D printing, and prototyping for industries like automotive and medical devices - predictive analytics provides a competitive advantage. It helps them stick to precise project timelines and avoid unexpected delays, reinforcing their commitment to high-quality, one-stop manufacturing solutions.

Looking ahead, the possibilities are even more exciting. With ongoing advancements in machine learning and sensor technology, CNC machining is set to evolve into fully autonomous, self-optimising systems. Manufacturers who embrace these innovations now will lead the charge into Industry 4.0, delivering faster, more reliable, and cost-efficient solutions.

This shift is creating smarter, more responsive manufacturing ecosystems that adapt to changing demands without compromising on quality or efficiency. Predictive analytics is becoming a cornerstone of modern CNC machining, seamlessly integrating with digital workflows to drive the future of manufacturing.

Predictive analytics is transforming CNC machining by leveraging real-time data and advanced algorithms to fine-tune processes and reduce errors. By identifying patterns and trends, it ensures tight tolerances are consistently met - often within an impressive range of ±0.0025 mm.

Another major benefit is predictive maintenance. By detecting potential equipment issues early, it helps minimise downtime and keeps operations running smoothly. On top of that, AI-driven quality control systems keep a close eye on production in real time, cutting defect rates and improving efficiency across the board. These technological advancements mean faster production, better-quality results, and a more dependable, cost-efficient approach to CNC machining.

Predictive maintenance plays a key role in keeping CNC machining operations running smoothly by spotting potential equipment issues before they turn into breakdowns. This forward-thinking approach helps avoid unexpected downtime by scheduling repairs during planned maintenance periods, keeping production on schedule.

By tackling problems early, predictive maintenance cuts down on expensive emergency repairs and helps CNC machines last longer. The result? Lower costs, consistent production quality, and improved efficiency - a smart strategy for streamlining manufacturing processes.

Predictive analytics plays a key role in improving CNC machining schedules by examining both real-time and historical data. It helps anticipate potential problems and fine-tune workflows. For instance, by spotting patterns that indicate equipment wear or possible failures, it allows for proactive maintenance. This approach helps minimise unplanned downtime and ensures production stays on schedule.

Beyond maintenance, predictive models are also valuable for operational planning. They assist in allocating resources more effectively and achieving production timelines with greater precision. The outcome? Streamlined operations, fewer delays, and a noticeable boost in overall productivity.