With the rapid penetration of consumer upgrading and intelligent electric vehicles, the traditional lighting attributes of headlights are being redefined. The function of

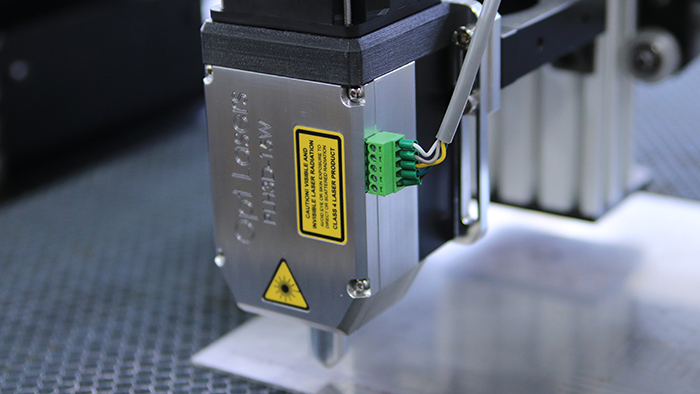

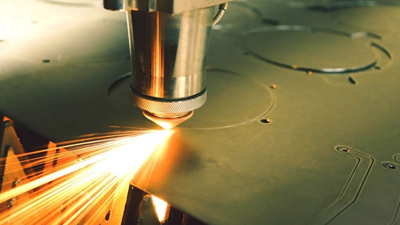

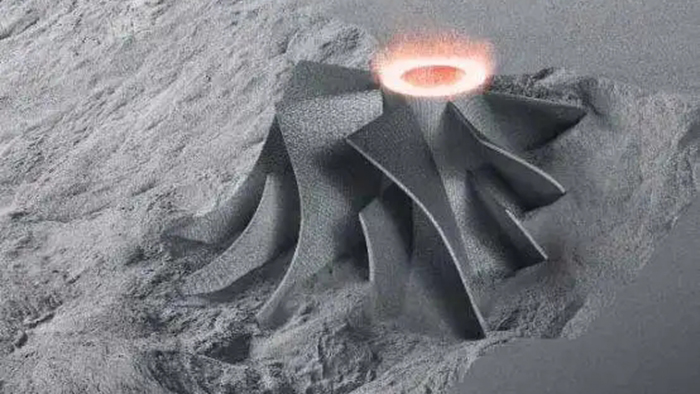

automotive lights is no longer limited to lighting, but integrates functions such as modeling, perception and interaction.We employ proven prototype technologies(

Rapid CNC machining, Vacuum casting, 3D printing etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk.

Whether it is through-headlights or light-emitting grilles, multi-color

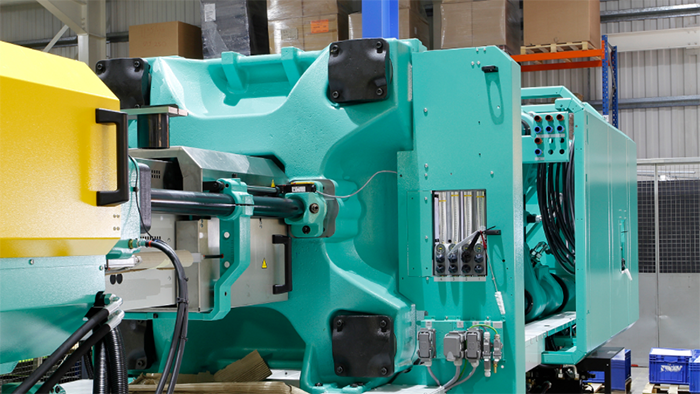

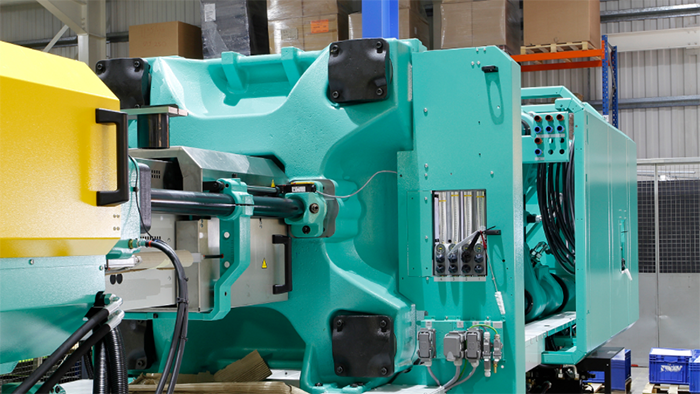

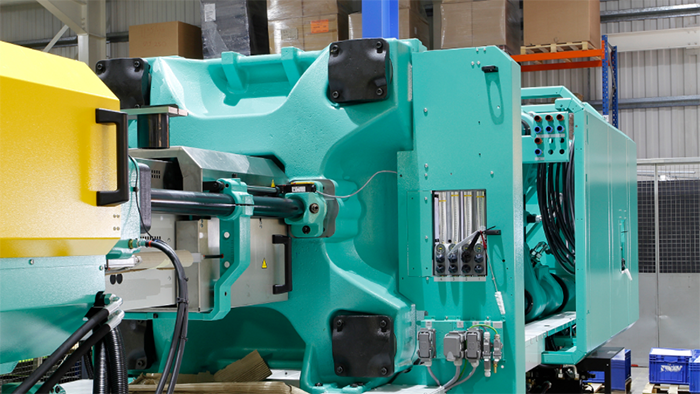

injection molding process can be used, which has strict requirements for material selection, mold precision and injection molding process.

In addition to lights and grille, touch intelligent surface, luxury texture decoration, pillar decorative plate, windows and other interior and exterior decorative parts that enhance the atmosphere of new energy vehicles are inseparable from the multi-color injection molding process.

Multi-color multi-material has the advantages of modularity, decoration, comfort, functionality, light weight and low cost in automotive injection molding. Specifically, it can make two-color or multi-color accessories without assembly through integrated molding and improve the freedom of modeling; it can realize the surface application of flexible materials such as TPE and reduce the connection link through soft and hard cladding.

However, multi-color injection molding has difficult equipment control, high cost as well as complex molds, the melting point difference between soft and hard materials require high pain points difficulties, need auto parts manufacturing enterprises and materials, equipment supply enterprises to cooperate to solve the problem.

Vehicle lights not only provide lighting and signal guidance, and with the improvement of environmentally friendly materials, multi-color injection molding and thick-wall process as well as chip and artificial intelligence level, more and more focus on environmental protection, aesthetics and intelligence, but also put forward new requirements for cost reduction and efficiency improvement of production efficiency."

Taking the processing of multi-color lamp shades as an example, two-color injection molding allows the shade to avoid the traditional lamp shade (lens) of the internal extraction line, and two-color lamp shade is equivalent to a molding of two pieces, but also very solid "assembly" together, saving labor, storage, logistics and other aspects of the loss.

"Multiple injections also give designers more design space, the current mainstream is black + transparent, later may be metallic + transparent, body color + transparent, etc.; block non-decorative parts through the gap between the mask and other parts to be found; prevent the light source from the side of the light leak, affecting the visual effect.