Prototyping is essential for turning ideas into tangible products across Australia's diverse industries. From Melbourne's automotive suppliers to Sydney's medical innovators, selecting the right method can save time, cut costs, and meet industry-specific demands. Here's a quick overview of four key approaches:

Choosing the right method depends on your project's complexity, volume needs, and compliance requirements. Each approach has its strengths, from 3D printing's rapid iterations to injection moulding's efficiency at scale. Combining these methods strategically can streamline the journey from prototype to production, ensuring Australian manufacturers stay competitive while meeting strict standards.

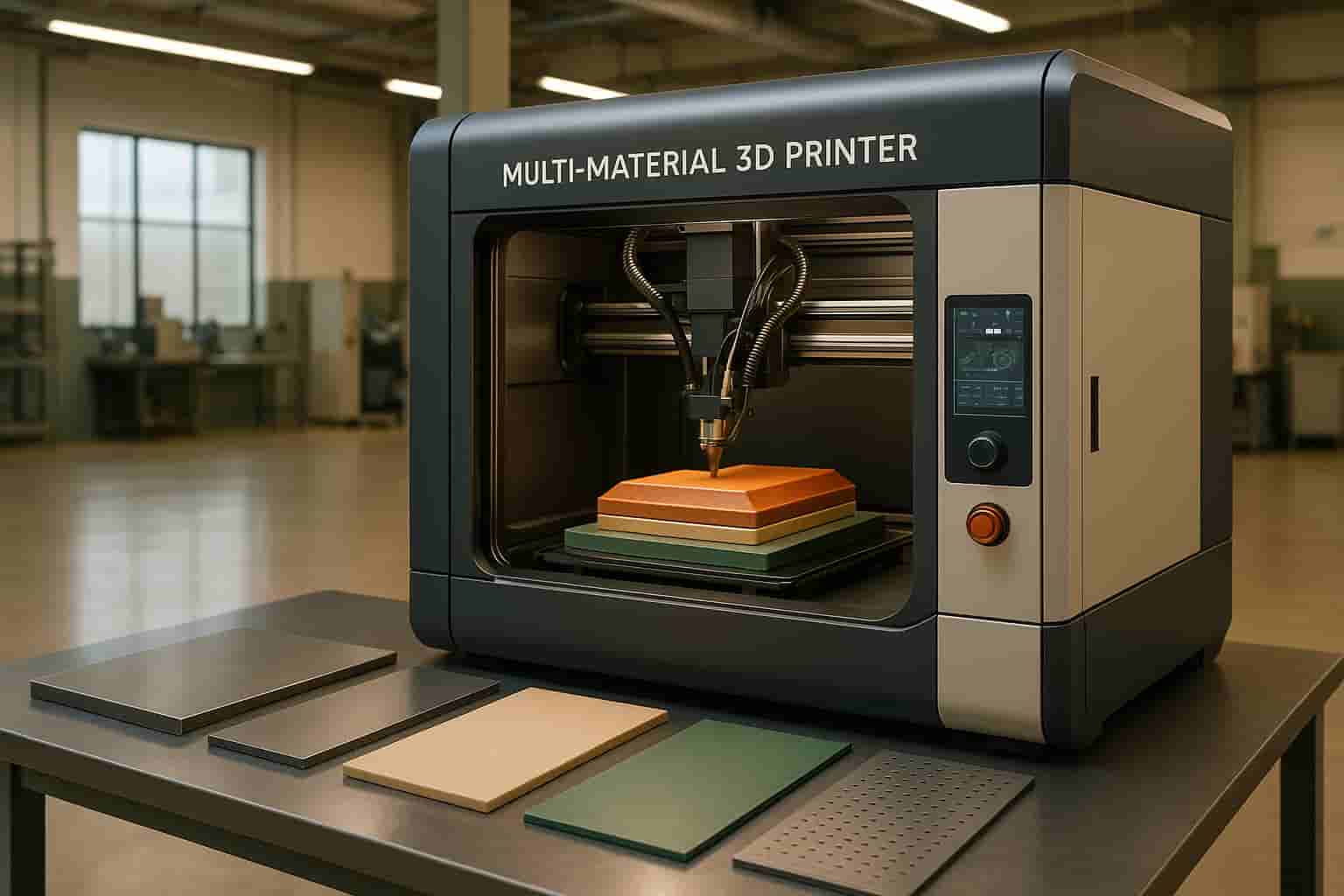

3D printing has reshaped how Australian industries approach prototyping, offering unmatched design flexibility and the ability to iterate quickly. By building objects layer by layer, this additive manufacturing technique makes it possible to create intricate designs that might be unachievable with traditional methods. This efficiency not only speeds up production but also brings cost advantages and helps meet strict compliance needs.

One of the biggest strengths of 3D printing lies in its speed, especially during the early stages of product development. Prototypes that once took weeks to produce can now be ready in mere hours. For industries like electronics and consumer goods, where time-to-market is a critical factor, this rapid turnaround is a game-changer.

Take medical device manufacturers in Melbourne and Sydney, for example. They can produce anatomical models or guides in just 24 hours. This speed allows for same-day adjustments, which is essential for creating custom implants or prosthetics. By enabling faster testing cycles, 3D printing helps reduce overall development costs while keeping projects on track.

Traditional manufacturing methods often come with hefty tooling and setup costs, but 3D printing eliminates these barriers. For Australian startups and small businesses, this means they can produce prototypes in small batches without worrying about high upfront investments or minimum order requirements.

The technology is especially economical for low-volume, highly complex parts. Unlike subtractive manufacturing, which generates significant material waste, 3D printing uses only the material required for the final product, along with minimal support structures. This reduction in waste not only saves money but also aligns with the need for efficient and precise prototyping in industries with strict standards.

Different industries have unique compliance and material certification requirements, and 3D printing can be tailored to meet them. For example, medical-grade materials are used to create biocompatible prototypes, while automotive-grade materials can handle extreme temperatures and chemical exposure.

Household appliance manufacturers benefit from food-safe materials, enabling them to produce functional prototypes that can undergo food contact testing. This is particularly useful for companies developing kitchen appliances or food processing equipment.

In regulated sectors, traceability is a key requirement. Digital workflows in 3D printing allow every detail - from print parameters to material batches - to be recorded and tracked. This digital documentation is critical for medical device manufacturers, who must maintain detailed records for regulatory approval.

Mastars supports these stringent demands by offering precise material selection and tightly controlled processes, ensuring compliance across various industries.

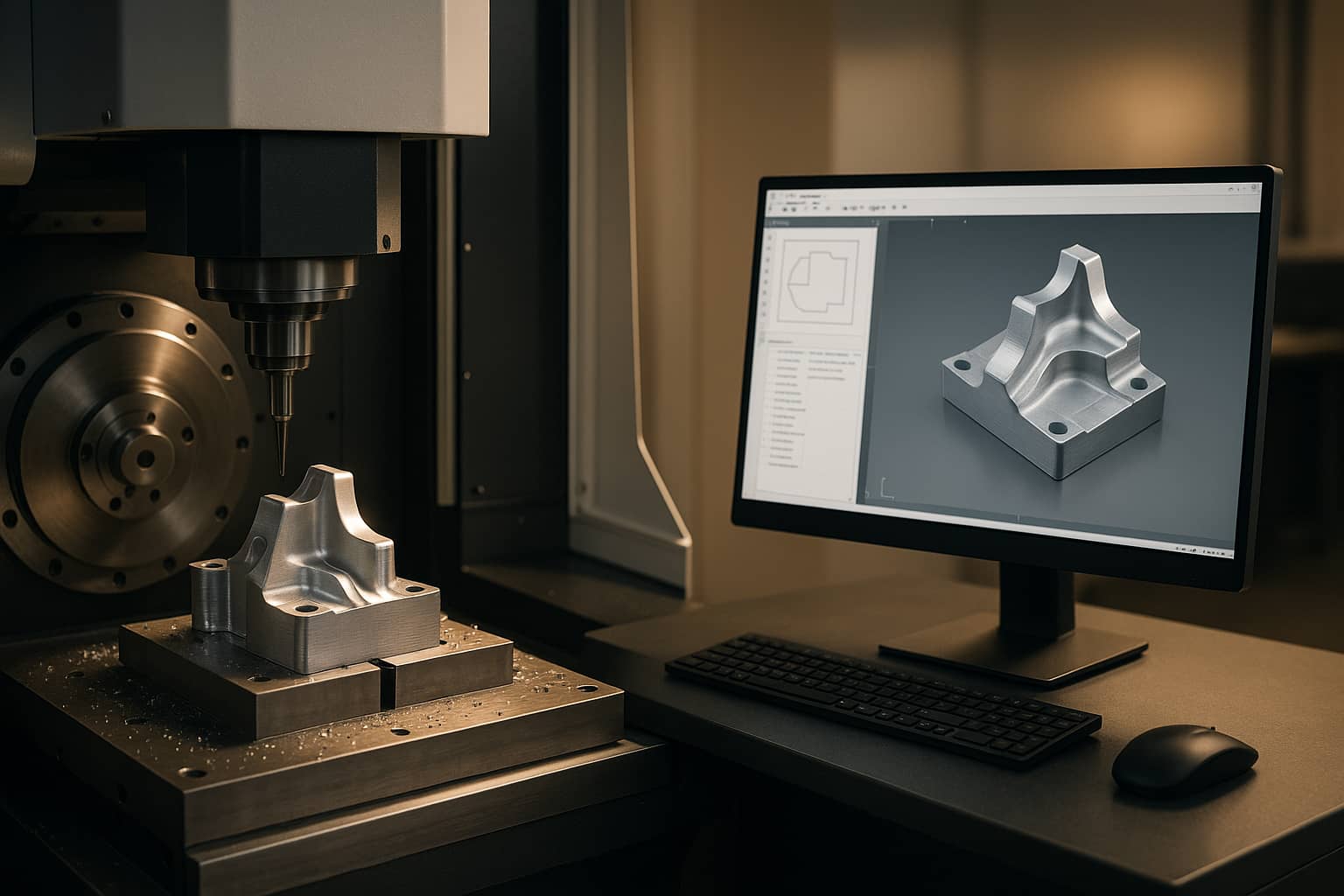

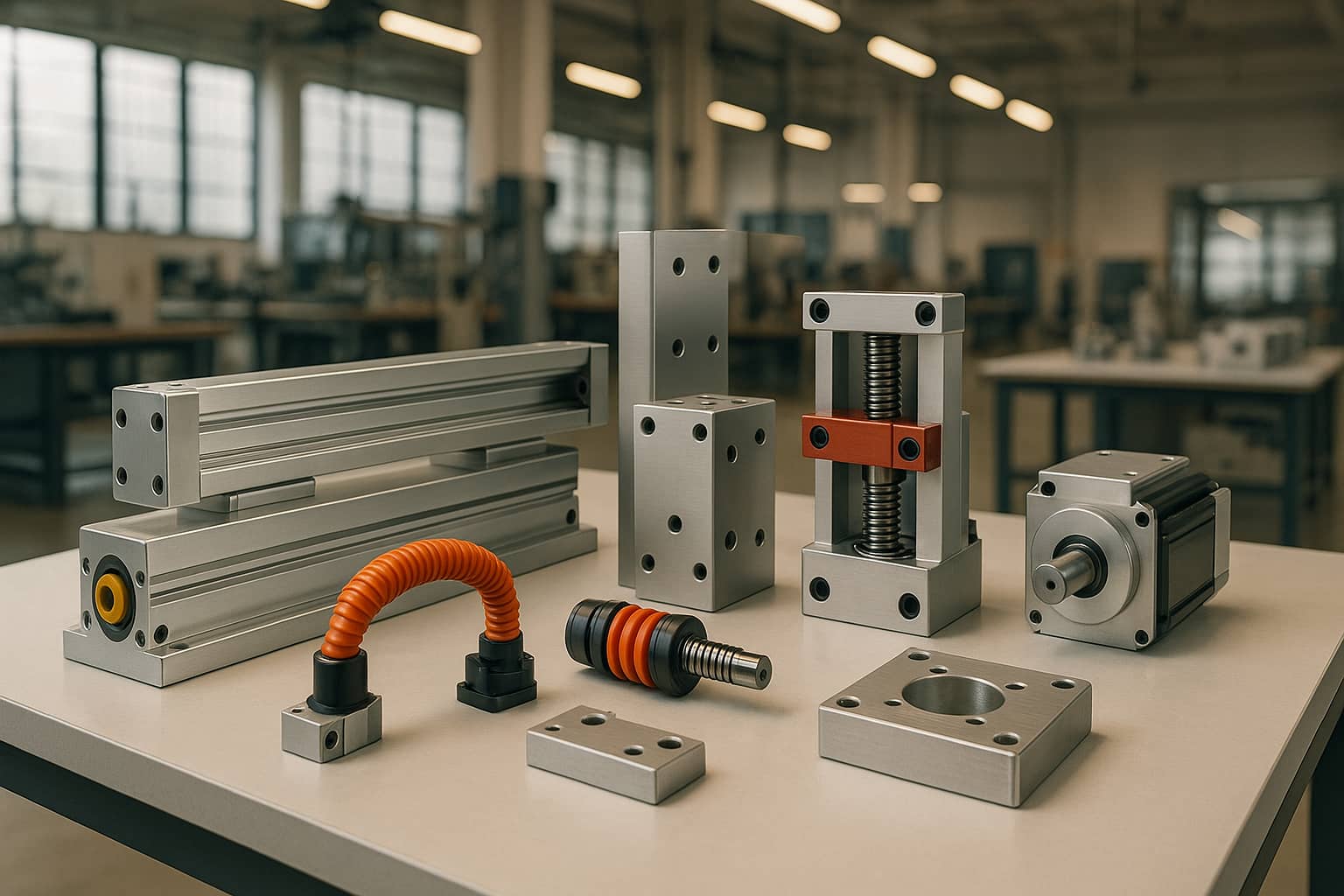

CNC machining is a key player in precision prototyping for many Australian industries. By removing material from solid blocks, this subtractive manufacturing process delivers unmatched accuracy and the ability to produce components with tight tolerances and strong mechanical properties. It’s a go-to method for creating everything from aerospace parts to medical implants, offering a reliable and adaptable solution for a wide range of needs. While additive manufacturing provides flexibility, CNC machining sets itself apart with its precision and scalability.

One of CNC machining’s standout features is its ability to seamlessly scale from prototype to production. The same CNC programs used for initial prototypes can be adjusted for full-scale production, ensuring consistency throughout the product lifecycle.

Take automotive manufacturers in South Australia, for example. When developing engine or transmission components, they can start with an aluminium prototype and later switch to production-grade materials like steel or titanium using the same toolpaths. This approach minimises risks associated with design changes between development and production stages.

Additionally, modular CNC systems make it easy to expand operations. Manufacturers can scale up by adding machines or running extra shifts without needing specialised tooling for different production volumes. Whether it’s a single prototype or thousands of units, CNC machining maintains a consistent setup, supporting efficient production while adhering to regulatory standards.

CNC machining is well-suited to industries with strict compliance requirements, thanks to its focus on material traceability and dimensional accuracy. Documented workflows and certified materials ensure that manufacturers meet the rigorous standards of sectors like aerospace and medical devices.

For medical device manufacturers, CNC machining works seamlessly with biocompatible materials such as titanium and medical-grade stainless steel. Each part can be traced back to its original material certificate, and the machining process generates detailed records of cutting parameters, tool changes, and quality inspections.

In aerospace, compliance requirements are even more demanding. Materials must be certified, processes validated, and dimensions meticulously inspected. CNC machining supports these needs by incorporating tools like coordinate measuring machines (CMMs) and statistical process control, creating detailed documentation that satisfies even the strictest regulatory bodies.

Mastars ensures these high standards are met by maintaining controlled processes and carefully selecting materials, making CNC machining a trusted choice for industries with demanding compliance needs.

CNC machining also shines when it comes to cost efficiency, especially when factoring in prototype functionality and long-term costs. By machining prototypes from final-grade materials, manufacturers can perform real-world testing without worrying about differences in material properties.

This efficiency is particularly evident in complex designs. A single CNC setup can handle tasks that might otherwise require multiple manufacturing steps, reducing handling and the chance of errors. This not only lowers costs but also shortens lead times.

For small to medium production runs, CNC machining often beats other methods like injection moulding, which comes with high upfront tooling costs. Australian manufacturers can create functional prototypes and limited production batches without the heavy investment required by traditional manufacturing techniques.

Vacuum casting is a practical prototyping method that bridges the gap between initial concepts and full-scale manufacturing. It uses silicone moulds and vacuum pressure to cast polyurethane or other resins, creating detailed replicas that closely resemble the final production materials and finishes. This makes it particularly useful for functional testing and market validation. When paired with CNC machining, vacuum casting provides a cost-effective way to achieve quality results during the early stages of product development.

This method is ideal for low to medium-volume production. A single mould can typically produce between 25 and 50 parts, lasting for 20–50 cycles depending on the complexity of the design and the materials used. For Australian businesses, this scalability is especially appealing, allowing for quick market validation or customisation without the hefty tooling expenses of injection moulding. It's a practical choice for small-scale productions under 100 units.

Vacuum casting stands out for its quick turnaround times and cost savings. Initial samples can usually be delivered within 5–15 business days, enabling fast design iterations and agile development. Compared to injection moulding, it can reduce costs by 30–70%. In Australia, small batch production costs typically range from AUD $150 to $500 per part, while creating the silicone mould costs between AUD $1,000 and $3,000. The reusable nature of these moulds cuts down on material waste and setup time, and if changes are needed, creating a new master model and mould is far quicker than retooling for injection moulding.

Vacuum casting also meets the high compliance standards required for regulated industries. With robust material traceability and precise dimensional accuracy, it’s an excellent fit for sectors like medical devices and automotive components that demand certifications such as ISO 13485 and ISO 9001. Companies like Mastars provide comprehensive vacuum casting services, focusing on material selection, detailed documentation, and validation processes. This ensures Australian businesses can meet regulatory requirements, including those set by the TGA and other industry benchmarks.

Injection moulding is a key method for transitioning from prototype development to large-scale production. By using thermoplastics and custom moulds under high pressure, this process creates durable and precise components. It's a go-to option for high-volume manufacturing, ensuring consistent quality and reliable material performance.

One of the standout features of injection moulding is its ability to scale efficiently. Building on earlier prototyping methods, it enables the production of complex parts in a single operation, making it an efficient choice for industries aiming for large-scale output. In Australia, this capability is particularly valuable, helping local manufacturers stay competitive in the global market while achieving production efficiencies.

While the initial tooling investment can be significant, injection moulding becomes highly cost-effective as production volumes increase. By precisely measuring materials and integrating multiple features into single components, the process minimises waste and reduces assembly costs. This results in lower per-part costs, which is especially beneficial for industries with strict quality and budget requirements.

Injection moulding is adaptable to meet the rigorous standards of industries such as medical devices, automotive, and food packaging. By maintaining tight controls on parameters like dimensional accuracy and material properties, the process ensures compliance with both local and international regulations. Companies like Mastars employ advanced quality assurance protocols to deliver components that meet these stringent requirements.

Choosing the right prototyping method depends on understanding its strengths and limitations, particularly when addressing the specific needs of Australian manufacturing. Each method comes with its own set of benefits and challenges, which can influence its suitability for different applications.

| Method | Scalability | Cost Efficiency | Speed | Compliance |

|---|---|---|---|---|

| 3D Printing | Best for low- to medium-volume production - ideal for rapid prototyping but less practical for high-volume runs. | Very economical for prototypes and small batches. | Provides quick turnaround for early-stage designs. | Useful for design validation, though material certifications may be limited in regulated industries. |

| CNC Machining | Suitable for medium to high volumes, delivering consistent quality across batches. | Cost-efficient for larger runs, though the subtractive process creates more waste. | Offers moderate turnaround times compared to initial prototyping methods. | Ensures excellent precision and meets strict tolerance requirements, critical for industries like aerospace and medical. |

| Vacuum Casting | Works for small to medium batches but limited by silicone mould durability (15–50 casts). | Highly cost-effective for short runs, avoiding expensive tooling. | Speeds up production once the mould is ready. | Produces parts with a smooth surface finish, ideal for functional testing. |

| Injection Moulding | Designed for mass production, excelling at high-volume efficiency. | High upfront tooling costs, but very low per-part costs at scale. | Longer setup time due to tooling, but rapid production thereafter. | Achieves high compliance, meeting rigorous standards across various industries. |

Each method also has unique technical considerations that affect its application. For instance, CNC machining provides parts with 40–60% higher tensile strength compared to 3D printing, making it a go-to option for projects requiring robust structural integrity, such as mining equipment or automotive parts.

Injection moulding stands out for its wide range of certified materials that meet demanding industrial standards. CNC machining, on the other hand, offers access to durable metals and engineering plastics. In comparison, 3D printing and vacuum casting currently have fewer material options, though these are steadily increasing. Additionally, CNC machining generates significantly more material waste due to its subtractive process, whereas 3D printing, being additive, produces much less waste. Vacuum casting falls somewhere in between, generating minimal waste compared to traditional machining methods.

Companies like Mastars blend these methods effectively, moving from rapid 3D printing for initial prototypes to full-scale injection moulding for mass production. This approach helps optimise both cost and time, showcasing how aligning prototyping methods with industry needs can enhance efficiency and drive progress in Australian manufacturing.

Selecting the right prototyping strategy is essential to align with your project's goals and industry expectations. In Australia, manufacturers who evaluate factors like design complexity, material requirements, and production volumes early in the process can allocate resources efficiently and bring products to market more quickly.

Real-world examples from various industries highlight the advantages of different prototyping methods. These examples illustrate how a structured, flexible approach can lead to better outcomes.

Incorporating rapid prototyping into scalable workflows has shown to cut rework and costs by up to 30% in manufacturing sectors. This method proves especially effective when starting with a single automated or prototyped process before expanding to broader operations.

Involving end-users, decision-makers, and suppliers early in the development process ensures prototypes meet expectations, reducing the need for expensive revisions. For instance, Australian appliance manufacturers have successfully used vacuum casting to create high-quality prototypes for user testing before committing to full-scale injection moulding.

The shift towards digitisation and simulation is opening up even more opportunities to lower costs and speed up iterations. Tools like digital twins and virtual testing allow manufacturers to validate designs before physical prototyping, streamlining the development process further.

For Australian manufacturers, working with integrated service providers simplifies the transition from prototyping to production. This approach ensures scalability, access to diverse technologies, and consistent quality across industries. Companies like Mastars exemplify this by offering end-to-end prototyping and manufacturing services that adhere to Australian standards, making the entire development cycle more seamless and efficient.

Keeping detailed records throughout the process will also help streamline future iterations and support efficient scaling.

To select the right prototyping method, Australian manufacturers need to weigh factors like speed of development, level of precision, and intended production volume. For rapid testing and quick design iterations, 3D printing is often a go-to option. On the other hand, CNC machining is better suited for creating highly precise and durable functional prototypes. When it comes to large-scale production, injection moulding becomes the preferred choice once the design is locked in.

Matching the prototyping method to your project's specific demands can help streamline costs and improve results. Collaborating with seasoned providers familiar with Australian industry standards can also ensure solutions are tailored to meet your exact needs.

Using multiple prototyping methods during product development offers a practical way to speed up iterations and address design issues early in the process. This not only saves time but also ensures the final product aligns with the project's specific goals.

By tailoring the approach to fit the unique demands of each project, combining prototyping techniques allows for greater adaptability and personalisation. This leads to better results, smarter resource allocation, and encourages fresh ideas. It's especially beneficial in industries like automotive and medical devices, where accuracy and efficiency are non-negotiable.

Advanced prototyping techniques, like 3D printing and CNC machining, are helping Australian businesses meet strict industry requirements. These methods deliver precise, dependable, and customisable solutions, making them essential for industries such as medical devices and automotive manufacturing.

With their ability to produce components swiftly, these technologies allow businesses to test and refine designs efficiently. This not only ensures regulatory compliance but also helps avoid unnecessary delays. Plus, their flexibility with different materials and design complexities makes them perfect for producing prototypes that meet both functional demands and compliance standards.