Molds and 3D printing complement each other|injection moiding services,metal printing service

On the flip side,

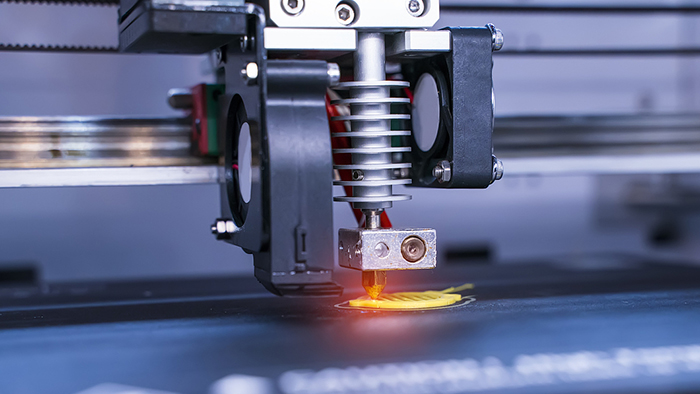

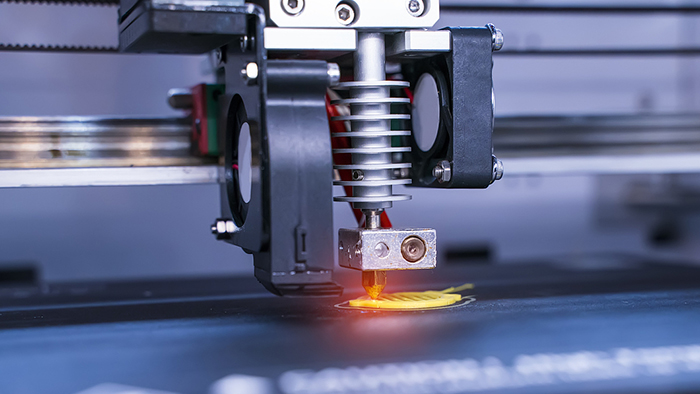

3D printing has made molds even more important. For example, Michelin acquired AddUp, a 3D printing equipment company, to explore the manufacture of tire molds through 3D printing technology. Because 3D printing has the ability to print complex shapes, metal 3D printing can be a good solution to the problem of tool interference, when complexity and manufacturability is no longer the biggest factor plaguing tire mold manufacturing,

3D printing can be a good way to release the ease of tire product design iteration, but also give rise to a new type of tire manufacturing capabilities.

Through 3D printing technology, Michelin has designed a unique sculpted series of tires, and 3D printing has become one of the decisive factors for Michelin tires to enhance their competitiveness.

In addition to the automotive field, in the production process of shoe sole molds, the traditional shoe making market, the production of shoe molds from design to a pair of finished shoe molds need to go through programming,

CNC machining, mold repair, mold testing, nibbling and other processes, the processing process is more complex, 3D printing technology compared to the traditional shoe making process is more intelligent, automated, with the advantages of saving people, efficient, accurate, flexible and so on.