Hybrid prototyping combines 3D printing and CNC machining to create prototypes that are both accurate and functional. This method leverages the strengths of each technology: 3D printing is ideal for complex internal designs, while CNC machining delivers precise surfaces and tight tolerances. It's a practical solution for Australian manufacturers facing challenges like tight deadlines, high-quality standards, and workforce shortages.

This approach addresses unique Australian manufacturing needs, such as compliance with strict standards, local material availability, and reducing reliance on international supply chains. It's a cost-effective way to produce prototypes that closely align with final production parts.

Partnering with an experienced provider like Mastars ensures access to both technologies under one roof, along with expertise in local regulations. This simplifies the prototyping process and ensures high-quality results.

Hybrid prototyping combines CNC machining and 3D printing to streamline Australian manufacturing processes. This approach requires careful planning and adherence to local standards to ensure efficiency and quality.

The process begins by identifying which features suit each method. 3D printing is ideal for creating complex internal geometries, lattice structures, and intricate channels. Meanwhile, CNC machining is reserved for areas requiring precision, such as threaded holes and tight tolerances.

This structured workflow ensures that each method is used to its strengths, allowing for efficient material use and precise machining setups.

Choosing the right materials and preparing machines correctly are critical for successful hybrid prototyping.

Hybrid prototyping in Australia must comply with strict local standards and address unique challenges like geographic isolation and workforce shortages.

Finally, integrating quality management systems that oversee both processes ensures that hybrid prototypes meet all functional and regulatory requirements. These systems include inspection protocols for verifying both the printed and machined features, guaranteeing the final product aligns with design specifications.

For Australian manufacturers, combining CNC machining with 3D printing offers a practical way to cut costs, boost efficiency, and improve product quality. This hybrid approach directly tackles common challenges in the local manufacturing landscape while refining production processes.

By integrating the capabilities of CNC machining and 3D printing, manufacturers can capitalise on the strengths of both technologies. 3D printing excels at creating intricate designs, while CNC machining ensures precision and a polished finish. Together, they provide a balanced solution:

| Benefit Category | 3D Printing Characteristics | CNC Machining Characteristics | Hybrid Approach Advantage |

|---|---|---|---|

| Speed | Slower for highly complex geometries | Optimised for simpler designs | Combines quick production with precision |

| Finish | Often produces a rougher finish | Delivers consistently smooth finishes | Polishes critical areas selectively |

| Accuracy | Offers moderate accuracy | Excels in high precision | Applies machining for precise dimensions |

| Material Cost Efficiency | Higher costs for specialised materials | Uses cost-effective standard stock | Reduces overall material costs |

| Internal Complexity | Ideal for intricate internal structures | Struggles with internal complexities | Preserves fine internal details while refining exteriors |

| Tolerances Achieved | Achieves looser tolerances | Known for tight tolerances | Applies CNC where precision is essential |

This hybrid method is particularly effective for designs requiring both complex internal geometries and high-quality surface finishes. By minimising setup steps and programming, it ensures efficiency while maintaining exceptional quality.

The approach also improves material usage. Instead of starting with a solid block and removing large amounts of material, 3D printing creates near-net shapes, and CNC machining refines only the critical areas. This reduces waste and streamlines production.

The combination of additive and subtractive techniques also enhances design flexibility. Engineers can create features like internal channels, lattice structures, or integrated assemblies - designs that would be difficult, if not impossible, to achieve with a single process.

Australia's manufacturing sector faces unique challenges, from small production runs to logistical hurdles due to the country's vast geography. Hybrid prototyping offers practical solutions to these issues:

Hybrid prototyping is reshaping Australia's manufacturing landscape by blending CNC machining with 3D printing. This combination allows manufacturers to create solutions that meet the country's strict regulatory standards and diverse market needs across industries such as automotive, medical devices, and household appliances.

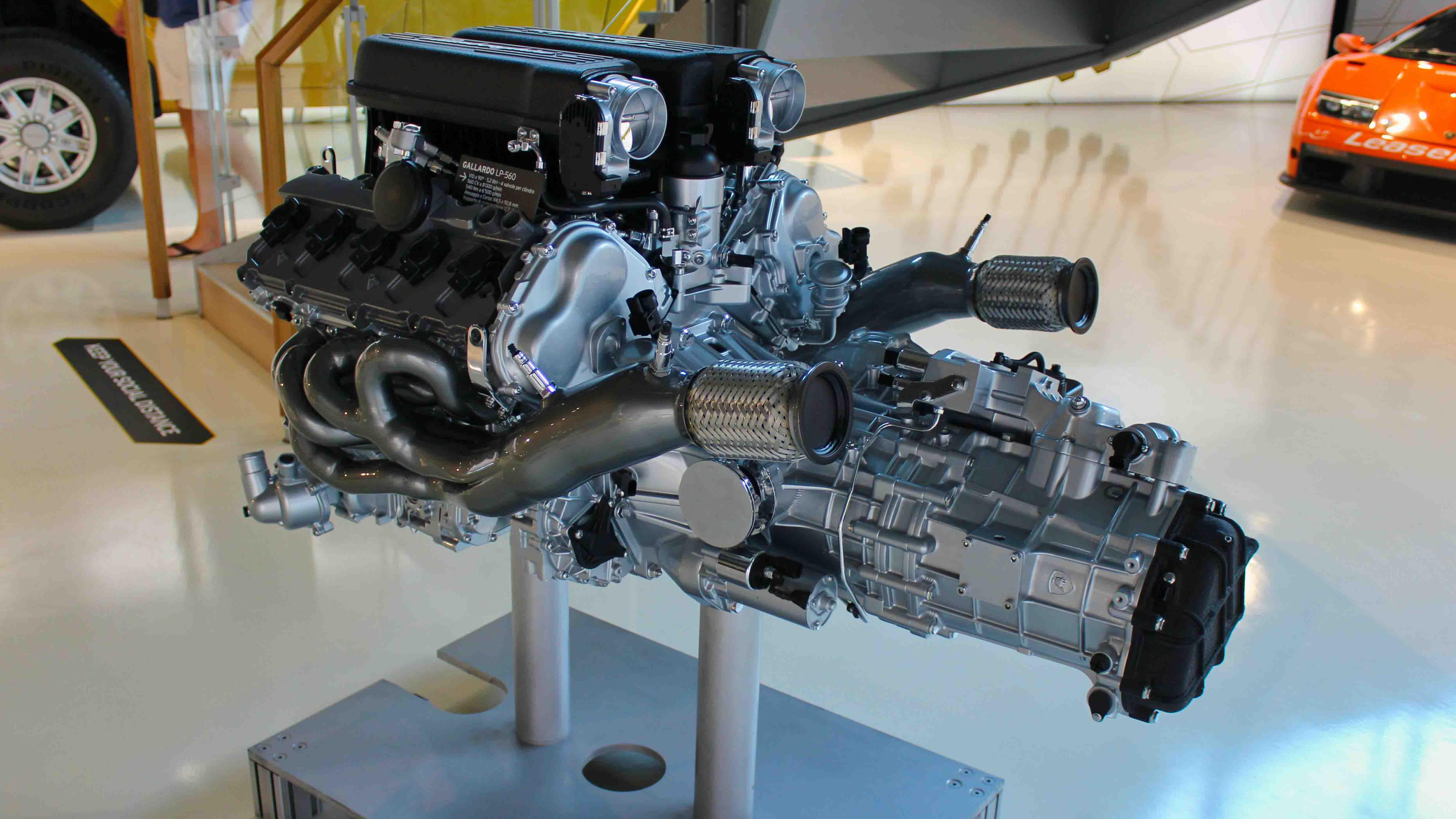

In the Australian automotive sector, hybrid prototyping is a game-changer for producing custom tooling, jigs, and specialised components. It's particularly effective for low-volume manufacturing and aftermarket parts, where intricate designs and precise tolerances are essential.

For example, local suppliers use this approach to create custom brackets, housings, and mounting systems for electric vehicle conversions. 3D printing enables the development of complex internal cooling channels and lightweight structures, while CNC machining perfects mounting surfaces to meet stringent safety requirements. This process not only ensures accuracy but also reduces costs compared to fully machined alternatives.

Engineers also rely on hybrid prototyping for rapid development of engine components, transmission parts, and suspension elements. This allows for quick testing of fit and functionality, followed by design refinements based on performance data. The result? Tailored solutions that align with the industry's push for innovation and customisation. These benefits extend beyond automotive applications, proving equally valuable in the medical field.

Australia's medical devices sector, governed by strict Therapeutic Goods Administration (TGA) regulations, also reaps significant benefits from hybrid prototyping. The process is ideal for creating compliant and customised products, such as surgical instruments and patient-specific devices like orthopaedic implants.

For instance, 3D printing can form ergonomic handles with optimised internal weight distribution, while CNC machining ensures the cutting edges meet the precise tolerances required for medical-grade performance. This combination not only accommodates surgeon preferences but also adapts to individual patient anatomies, all while adhering to Australian standards.

Hybrid prototyping also supports rigorous testing and validation. Functional prototypes can undergo the stringent protocols necessary for TGA approval, ensuring both intricate internal features and precise external dimensions are up to par. Moreover, the use of biocompatible materials ensures prototypes align with the standards for final production, making this approach an invaluable tool for Australia's demanding medical sector.

In the household appliance industry, hybrid prototyping accelerates the development of products that meet high standards for precision, safety, and energy efficiency. It's a go-to method for creating prototypes of kitchen appliances, including blender housings, coffee machine components, and food processor parts.

3D printing is used to design intricate internal mechanisms that optimise fluid flow or mechanical performance, while CNC machining refines threads, sealing surfaces, and mounting points for a perfect fit. This approach is equally effective for white goods like washing machines, refrigerators, and air conditioning systems, where engineers can evaluate thermal performance, vibration resistance, and durability under Australia's diverse conditions.

Prototypes developed through hybrid methods are designed to meet Australian electrical safety standards, energy efficiency benchmarks, and consumer protection regulations. This process ensures that functional test units closely mimic final production models, allowing for effective market testing and rapid adjustments to control interfaces or functional elements. By integrating additive and subtractive processes, hybrid prototyping delivers reliable, regulation-compliant designs tailored to Australian needs.

Selecting the right hybrid prototyping partner can make or break your project timelines, budgets, and adherence to both local and global standards. To simplify your development process, it's essential to focus on the attributes that matter most.

Start by assessing their technical capabilities. A strong partner will offer both CNC machining and 3D printing services under one roof, eliminating the hassle of coordinating multiple suppliers and cutting down on lead times. Look for providers equipped with a range of CNC machines capable of working with materials like aluminium, steel, and high-performance polymers, alongside industrial-grade 3D printers for everything from prototypes to production runs.

Make sure the partner has robust quality systems in place. This includes calibrated equipment, detailed inspection reports, and experience adhering to Australian standards. This is particularly important for industries like medical devices and automotive, where precision and compliance are non-negotiable.

It's also crucial to choose a partner familiar with local regulatory requirements. They should understand guidelines such as TGA standards, Australian Design Rules, and electrical safety regulations to help you avoid costly redesigns and navigate the unique challenges of manufacturing in Australia.

Consider their lead times for various project complexities. A reliable partner will stock commonly used materials locally, reducing delays. While simple prototypes might be delivered quickly, more intricate designs could take longer, so it's essential to confirm their turnaround times.

Lastly, prioritise partners with dedicated project management. Regular updates, clear communication, and modern tools ensure you stay informed at every stage of the prototyping process.

When it comes to meeting these criteria, Mastars stands out as a leading hybrid prototyping provider in Australia. They offer a comprehensive solution that includes CNC machining, 3D printing, vacuum casting, and sheet metal prototyping - all under one roof.

By consolidating these services, Mastars eliminates the complexity of dealing with multiple suppliers. Their integrated approach ensures that each technology works seamlessly together, which can significantly streamline your project timeline.

Mastars has extensive expertise across sectors such as automotive, medical devices, and household appliances. They are well-versed in local regulatory requirements, ensuring your prototypes align with Australian standards from the outset - minimising the risk of costly revisions later in the process.

Additionally, Mastars leverages cutting-edge manufacturing technologies, including Industry 4.0 systems, to deliver high precision and repeatability. Their rigorous quality control processes, supported by calibrated equipment and documented procedures, meet the demanding needs of regulated industries, giving you confidence in their capabilities.

Hybrid prototyping combines the precision of CNC machining with the adaptability of 3D design, streamlining the development process without compromising on quality. This blend of technologies allows Australian manufacturers to produce prototypes that closely represent the final product - an essential capability in the competitive manufacturing sector.

By adopting this method, companies can cut lead times, optimise material usage, and test both the form and function of a product in a single prototype. It's a solution that aligns with Australia's stringent standards across various industries.

To fully leverage these benefits, it's essential to work with a partner skilled in both CNC machining and 3D printing, and well-versed in Australian regulations, such as the TGA and Australian Design Rules. Mastars exemplifies this expertise, offering integrated services that remove the hassle of managing multiple suppliers. Their deep understanding of regulated industries and local compliance ensures prototypes are developed accurately from the outset.

With a partner like Mastars, hybrid prototyping doesn't just speed up the process - it elevates the entire product development journey. This approach enables the creation of products that meet the rigorous demands of both Australian and international markets.

Hybrid prototyping merges CNC machining with 3D printing, creating an efficient and economical approach for Australian manufacturers. By blending these two technologies, businesses can simplify production, cut down on material waste, and reduce the need for extensive tooling. The result? Shorter production timelines and lower overall costs.

This method is particularly versatile, enabling quick design updates and tailored solutions, which are crucial for industries that demand precision and adaptability. Plus, leveraging the combined strengths of CNC machining and 3D printing not only boosts product quality but also helps meet tight deadlines - offering a strong edge in Australia's competitive manufacturing landscape.

Hybrid prototyping, blending CNC machining with 3D printing, is helping Australian manufacturers address pressing issues like rising production costs, skills shortages, and supply chain challenges. By simplifying the prototyping process, it enables quicker and more affordable development of quality products.

This approach also offers greater adaptability, allowing businesses to respond to changing global markets and trade uncertainties. By moving away from outdated equipment and encouraging local advancements, hybrid prototyping is becoming a key driver in bolstering Australia's manufacturing industry on the global stage.

Working with a hybrid prototyping partner familiar with Australian regulations is crucial for ensuring your project aligns with local standards. This means adhering to laws such as the Therapeutic Goods Act 1989 for medical devices and meeting other manufacturing requirements. Staying compliant can save you from expensive delays, legal troubles, or unexpected hurdles during product development.

A well-informed partner can help simplify the approval process, ensuring your prototypes meet safety, quality, and environmental benchmarks, like RoHS compliance. This is especially important in highly regulated fields like healthcare, where precision and strict adherence to local guidelines are key to achieving success.