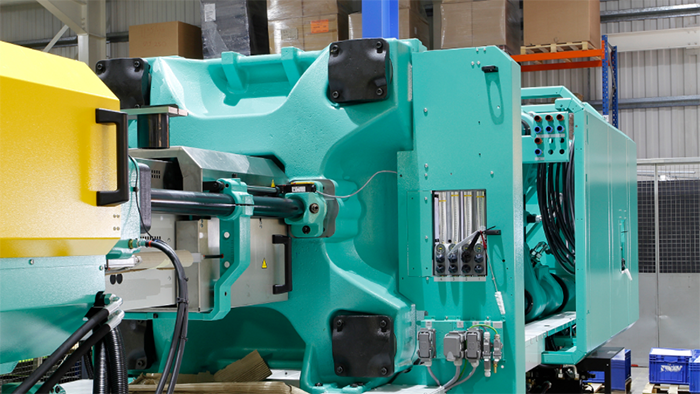

Mastars has rich experience in automobile interior and exterior decoration manufacturing. We provide injection molding, rapid CNC services, and 3d printing services

Instrument panel system

The instrument panel is one of the most important functional parts of the interior and one of the most complex systems in terms of structure and manufacturing process. It protects the safety of the personnel together with the seats and airbags, and therefore has high requirements for its shape, texture, comfort and occupant protection. The dashboard body can be divided into hard dashboard and soft dashboard according to its surface texture.

Instrument panel body materials and technical requirements.

★ Bending modulus≧1800MPa.

★ Notched impact strength≧18KJ/m2;

★ Maximum heat-resistant temperature 110≧℃;

★ The minimum heat-resistant temperature -40 ℃.

★ Sassafras resistance≧4N,6N,10N, △E≦1.5.

Instrument mask

Instrument mask mainly to ABS, ABS / PC, enhanced PP and other materials injection molding. ABS, ABS / PC difficult to meet the heat-resistant requirements, the price is also more expensive than enhanced PP, but the surface treatment is easy, can be painted, chrome, water transfer printing, etc., to meet the modeling requirements; enhanced PP can meet the heat-resistant requirements, but it is difficult to personalize the surface treatment. The choice of material is weighed according to actual needs and price.

Center Control Panel

The central control panel in the central area of the instrument panel, directly affect the effect of the instrument panel modeling, the host factory often through the change of the shape of the central control panel or surface treatment of the old implementation of small changes, small changes in the effect, requiring a better personalized surface treatment. Due to the frequent maintenance needs of electronic or air conditioning parts, to facilitate the installation and disassembly, there are certain requirements for strength and toughness. In the design process, the central control panel is generally selected ABS, ABS/PC, surface painting, chrome plating, wood grain water transfer printing, etc..

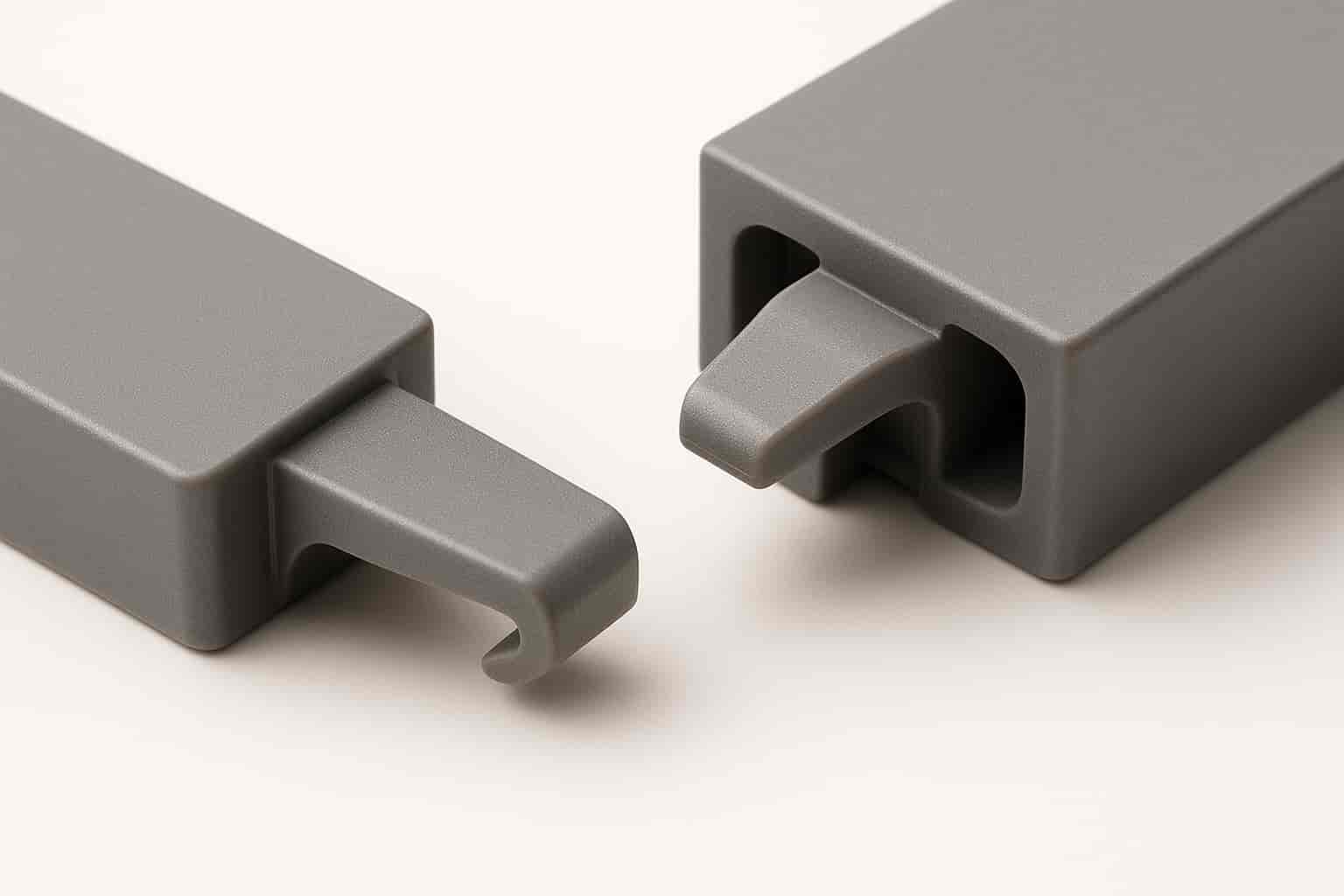

Glove box

The glove box mainly plays the role of storing items and protecting the knees of the occupants, the appearance and texture need to be consistent with the instrument panel, sometimes need to do additional appearance treatment.

The inner and outer panels of the glove box are generally made of modified PP or PC/ABS injection molding, and luxury cars use flocking process in the interior to avoid the noise generated by the stored items while driving. Glove box accessories such as handles, pivot pins, card sheds, clips, more use of POM material, can resist repeated impact and wear.

Air outlet

The air outlet is divided into front and rear air guide blade, air outlet seat, air door blade, knob switch, as shown on the right. The air outlet of the car air conditioner, need to often dial, and hot and cold changes in airflow, requiring materials can be high heat resistance, impact resistance, flexibility and dimensional stability, the recommended material blade using PA6, ABS/PC, air outlet seat using ABS or PP + T, air door blade can choose PP + T for its skeleton, EPDM for its seal, knob switch assembly is required POM, TPO, etc. Wear-resistant materials.