Lower Tooling Costs & Faster Lead Times

Traditional methods like injection molding require expensive tooling and molds. For small batches or prototypes, the tooling cost alone can exceed the value of the parts produced. 3D printing eliminates or reduces tooling, cutting upfront costs and lead time. Mastars’ CNC machining and 3D printing services deliver rapid results from CAD to production.

Design Freedom & Complexity

OEMs often need parts with complex geometries or lightweight structures. Additive manufacturing enables designs that are impossible with traditional processes. For example, automotive OEMs use 3D printing for lightweight, high-performance parts (Raise3D).

Flexibility & Customization: High-Mix, Low-Volume

OEMs often produce multiple SKUs or variants. Low-volume production with 3D printing supports high-mix manufacturing and customization without costly retooling. Mastars provides flexible additive workflows (LuxCreo).

Reduced Inventory & On-Demand Production

Holding large inventories ties up capital and storage space. 3D printing enables on-demand production of spare parts and low-volume runs. Mastars offers fast, efficient production for OEMs in Australia and Europe (AMFG).

Market Trends in Australia & Europe

The Australian 3D printing market was valued at AUD 692.45 million in 2024 and is projected to grow at 18.7% CAGR through 2034 (Expert Market Research).

In Europe, the 3D printing market is forecast to grow from USD 6.84 billion in 2025 to USD 13.17 billion by 2030 (Mordor Intelligence).

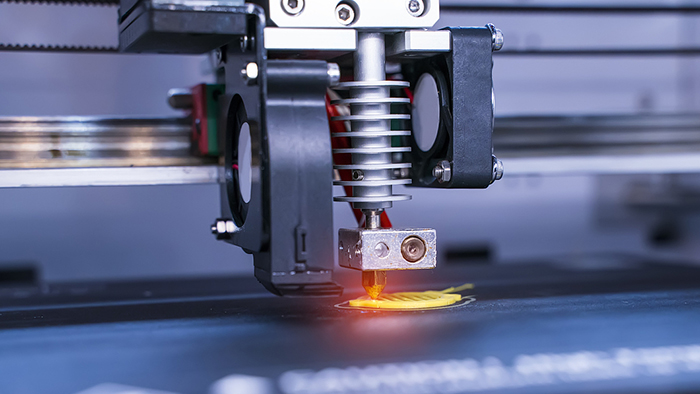

Quality, Materials & Tolerances

Modern 3D printing processes like SLS, SLA, and metal powder bed fusion deliver parts with strong mechanical properties and tight tolerances. Mastars combines additive manufacturing with precision machining to ensure parts meet OEM standards.

Supply Chain Resilience & Sustainability

Local low-volume production reduces reliance on global supply chains. Additive manufacturing uses only required material, producing less waste. Mastars supports OEMs in adopting sustainable production practices in Australia and Europe.

Use Cases & Industries

Automotive Applications

Custom components, lightweight structures, and legacy car spares.

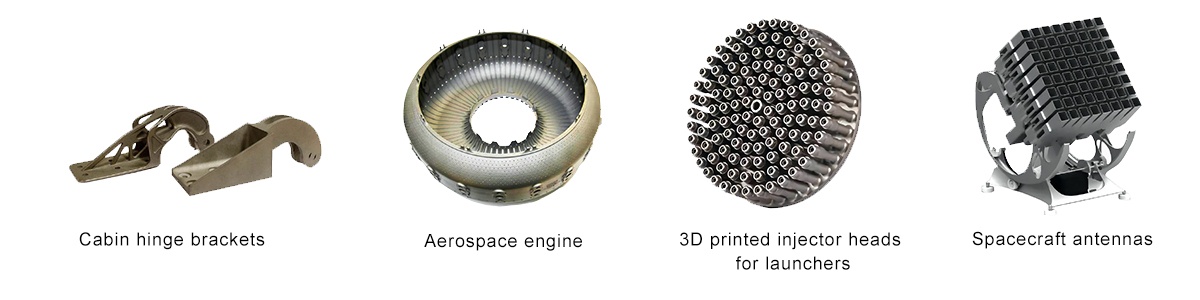

Aerospace Applications

Lightweight brackets and complex geometries for critical parts.

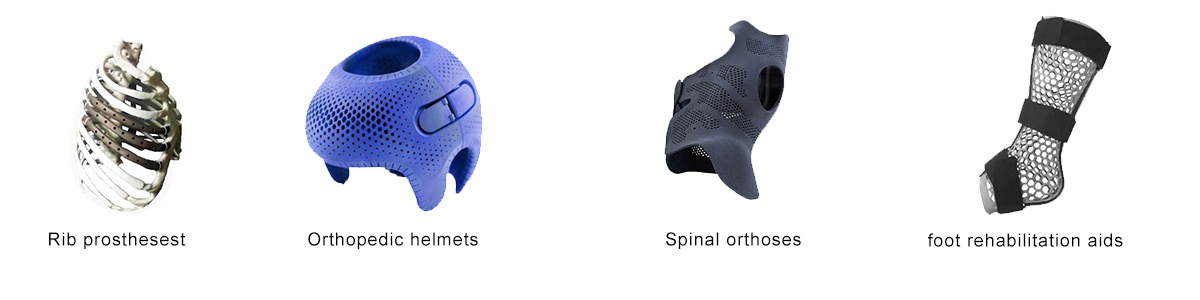

Medical Applications

Custom implants, surgical models, and patient-specific prosthetics.

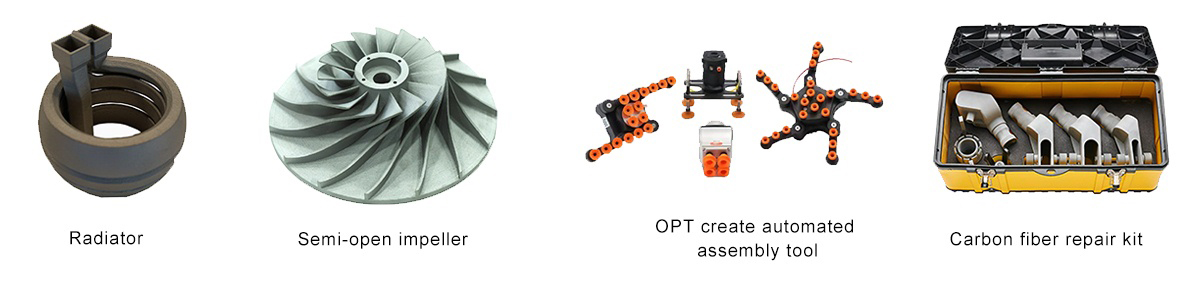

Industrial Equipment

On-demand spare parts for legacy machinery and industrial tools.

Cost Break-Even: 3D Printing vs Traditional Methods

For very large volumes, injection molding remains more economical. But for low-volume production, customization, or frequent updates, 3D printing is cost-effective. Mastars helps OEMs compare costs and select the right method.

How Mastars Supports OEMs in Australia & Europe

Mastars provides high-quality 3D printing (polymers, resins, metals), CNC machining, mold making, and prototype development. We deliver flexible order sizes, quality assurance, and logistics support for OEMs in Europe and Australia.

Conclusion

For OEMs in Australia and Europe, the benefits of 3D printing in low-volume production are clear: lower tooling costs, faster lead times, customization, and design freedom. Mastars helps OEMs integrate additive manufacturing into their production strategy.

Contact Mastars today to discuss your next low-volume manufacturing project.