Post-production delays in manufacturing can disrupt schedules, strain supply chains, and hurt customer trust. Here's what you need to know:

Australian manufacturers face unique challenges like geographic isolation and lean inventory systems. Companies like Mastars address these issues by offering a one-stop manufacturing model, advanced monitoring systems, and transparent communication to minimise delays and maintain efficiency.

Takeaway: Identifying root causes and adopting efficient processes can reduce delays, cut costs, and improve customer satisfaction.

Understanding what goes awry in post-production is essential to addressing the root of the problem. Australian manufacturers frequently encounter recurring issues that not only disrupt schedules but also strain professional relationships. These problems often snowball - what starts as a minor inconvenience can escalate into significant operational setbacks. Below, we explore some of the most common challenges and their ripple effects.

Parts shortages and inconsistent quality are major culprits behind production halts. Global supply chain disruptions have revealed how vulnerable manufacturers can be, especially those heavily reliant on international suppliers. A part that performed flawlessly during prototyping might suddenly fail quality checks when scaled for mass production, creating unexpected roadblocks.

Australia’s geographic isolation compounds these challenges. Port congestion, customs delays, and limited freight capacity can stretch delivery times from a few days to several weeks. Even domestic suppliers aren’t immune to transportation issues - moving goods between major cities or to regional manufacturing hubs often poses logistical difficulties.

Fragmented supply chains add another layer of complexity. When components are sourced from multiple suppliers across various time zones, coordinating deliveries becomes a logistical juggling act. Miscommunication between suppliers, freight companies, and manufacturers can lead to mismatched expectations and missed deadlines, further derailing production schedules.

When products fail quality checks late in the process, manufacturers are left with tough choices: scrap the batch or invest in costly rework. These failures often surface during final assembly or packaging, directly impacting delivery timelines and creating additional stress.

Quality standards that vary between production runs or shifts only make matters worse. Inconsistent quality control procedures can lead to products that technically meet specifications but fall short of customer expectations. This often triggers last-minute design adjustments or unplanned quality assurance steps, throwing schedules into disarray.

Rework, while intended to fix problems, can spiral out of control. What starts as a minor fix for a small batch can quickly escalate into a full-scale overhaul, consuming more time and resources than the original production. The situation becomes even more challenging when specialised skills or equipment are required, further extending delays.

Poor documentation adds another layer of difficulty. Without clear records, identifying the root cause of quality issues takes longer, delaying corrective actions. This can result in broader quality holds, affecting multiple product lines and compounding delays.

Many manufacturing facilities still rely on paper-based systems, which slow down post-production workflows. When critical information has to be manually transferred between systems or departments, errors and delays are almost guaranteed. These inefficiencies are especially problematic during shift changes or when key team members are unavailable.

Communication breakdowns are another frequent issue. Poor feedback loops, slow client approvals, and inadequate change management processes create information silos. When problems arise, valuable time is wasted as departments scramble to understand the scope and urgency of the issue. This reactive approach often leads to further delays.

Last-minute design changes or updates to specifications can also wreak havoc. If this information doesn’t reach all relevant team members in a timely manner, products may be manufactured to outdated specifications. This results in costly rework or, in extreme cases, the need to reproduce entire batches.

Equipment reliability is a cornerstone of efficient production, but unexpected machinery breakdowns can bring everything to a halt. Delays are often exacerbated by limited spare parts inventories and insufficient cross-training among staff, leaving manufacturers scrambling to get operations back on track.

In an effort to avoid production interruptions, some manufacturers defer maintenance, unwittingly setting the stage for larger issues down the line. When specialised components fail, waiting for replacements - especially from overseas suppliers - can stretch delays even further. This is particularly problematic for older machines, where finding spare parts can be a challenge.

Another issue is the reliance on a few key individuals who hold the expertise to operate complex machinery. These single points of failure can derail entire production schedules if those individuals are unavailable. As manufacturing becomes more digitised, software and system integration problems are also becoming a growing concern. When systems don’t communicate properly or software updates create compatibility issues, downtime can be both extensive and unpredictable.

These challenges highlight the importance of streamlining processes and ensuring systems work together seamlessly to minimise costly delays in post-production.

Post-production delays often show up in clear ways - missed deadlines, quality issues, or equipment breakdowns. But beneath these symptoms lie technical challenges that create deeper inefficiencies. For Australian manufacturers, tackling these issues is key to improving production efficiency.

A lack of real-time visibility across supply chains creates blind spots that often come to light too late. Many Australian manufacturers rely on disconnected systems for suppliers, logistics, and internal teams, leading to information silos. These silos prevent decision-makers from having a clear view of operations.

Take this example: a shipment of critical components gets delayed at a Melbourne port. The production team in Adelaide might not learn about the delay until the delivery date has already passed. By then, the entire production schedule is disrupted, and finding alternatives becomes both costly and time-consuming.

The problem worsens with manual data entry and inconsistent data formats. Without standardised systems, creating unified dashboards or setting up automated alerts becomes a near-impossible task. Managers end up wasting valuable time gathering information manually instead of focusing on strategic decisions.

Australia’s geographic isolation adds another layer of complexity. Simple updates can turn into lengthy, multi-party communications across continents and time zones, further slowing down the process. And while supply chain fragmentation is a major issue, scaling production introduces its own set of technical hurdles.

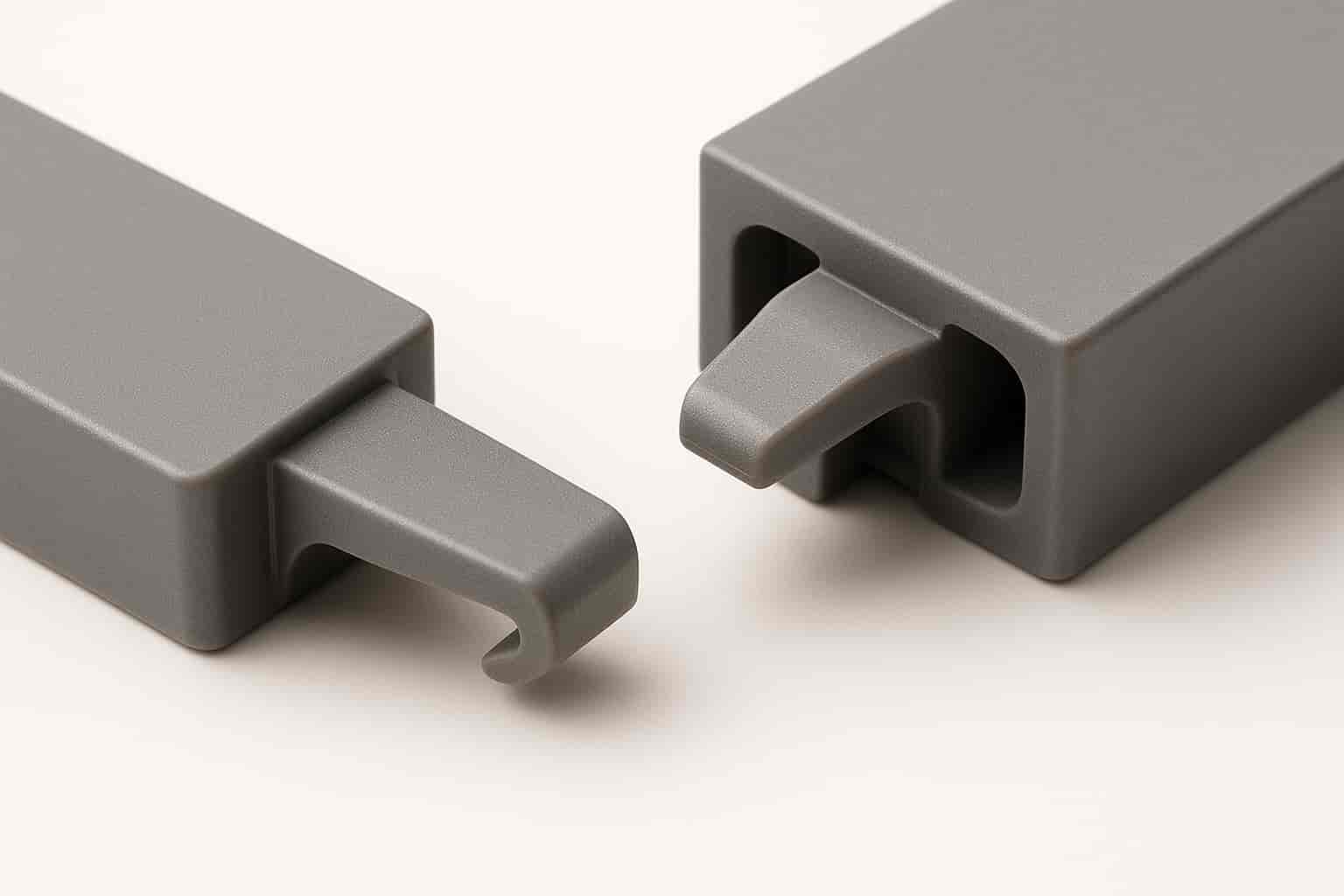

Moving from successful prototyping to mass production often reveals process misalignments that weren’t apparent before. Methods that work well for producing 10 or 50 units often fall apart when scaled to thousands, leading to bottlenecks and quality issues.

For instance, prototype tooling - designed for flexibility rather than durability - often fails under the strain of mass production. Using such tooling for larger runs can result in faster wear, inconsistent product quality, and frequent breakdowns, all of which disrupt production.

Quality control processes also face challenges. Manual inspections that worked for small batches become impractical and error-prone when applied to larger volumes. This often means quality issues are identified late, requiring costly rework or even the rejection of entire batches.

Another common issue is supplier capacity constraints. Suppliers who can easily handle small prototype orders may struggle to meet the demands of mass production. This forces manufacturers to either accept longer lead times or scramble to find new suppliers - both of which can derail production timelines.

Finally, informal or incomplete process documentation during prototyping becomes a liability during scaling. Without detailed, standardised procedures, inconsistencies in quality, timing, and resource use multiply, throwing off carefully planned production schedules.

Relying on reactive maintenance leads to unpredictable equipment failures, which can halt production lines entirely. Traditional maintenance methods lack the data-driven insights needed to predict and prevent problems, resulting in costly emergency repairs and extended downtime.

For Australian manufacturers, unplanned downtime is particularly expensive, with median costs often reaching hundreds of thousands of dollars per hour for critical equipment. Beyond repair expenses, these disruptions lead to lost production, expedited shipping costs, and even penalties for late deliveries.

The limited use of automation in monitoring and maintenance processes means many potential issues go unnoticed until they cause major failures. Without continuous monitoring of performance metrics, maintenance teams are left in the dark, unable to address problems proactively.

Predictive maintenance could significantly reduce downtime - studies suggest it can lower equipment downtime by 30-50%. However, many Australian manufacturers still rely on scheduled maintenance, which can either waste resources if done too often or risk failures if done too infrequently.

Barriers to adopting predictive maintenance include high upfront costs, skill gaps among staff, and difficulties in integrating new systems with older equipment. These challenges prevent manufacturers from fully benefiting from predictive technologies.

The absence of digital twin technology further limits proactive management. Digital twins allow manufacturers to simulate operations, monitor key metrics, and detect anomalies early. Without these tools, manufacturers are stuck in a reactive cycle. By integrating predictive maintenance, companies like Mastars shift from reactive approaches to proactive systems, reducing downtime and improving efficiency.

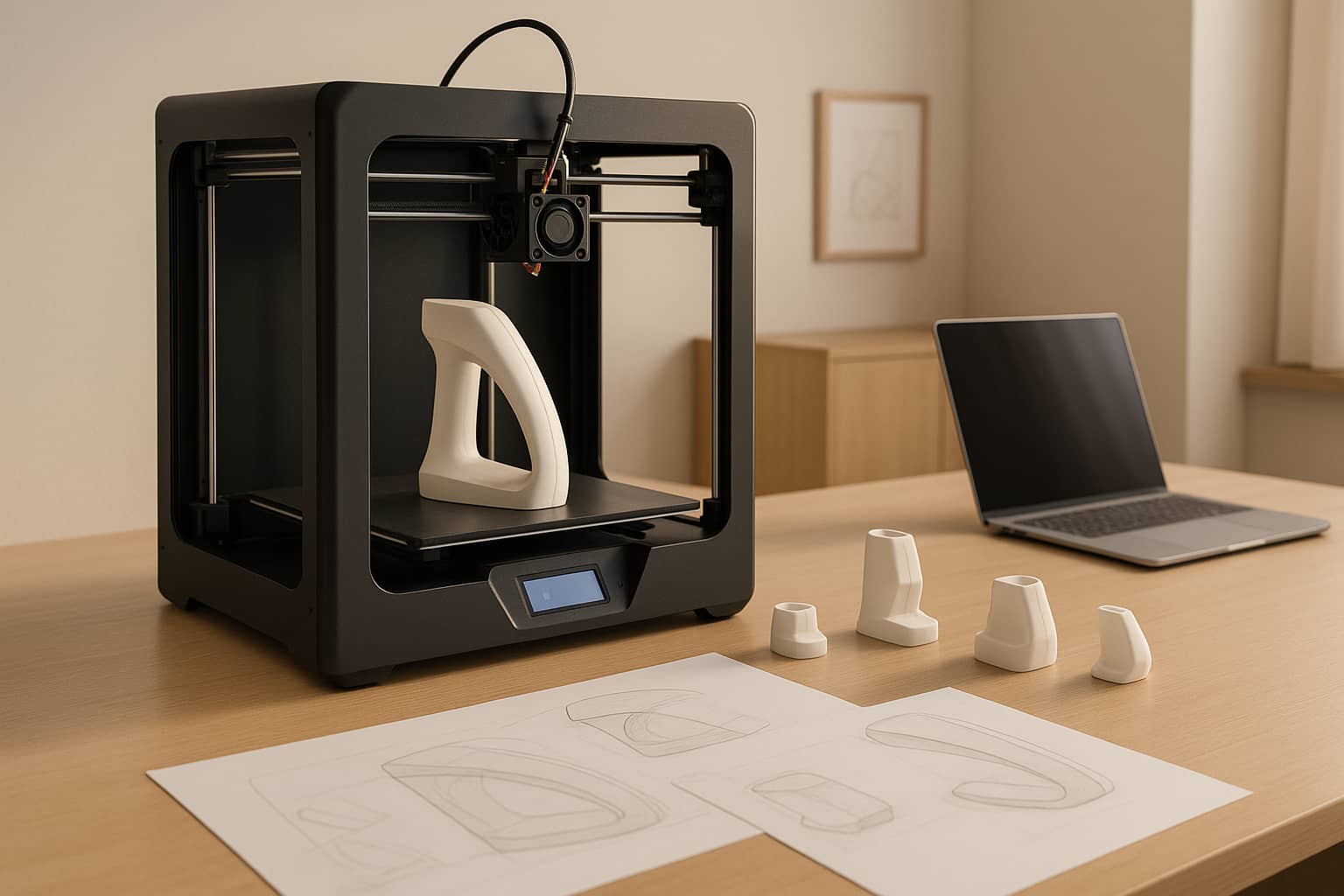

Mastars tackles post-production delays head-on by combining cutting-edge technology with efficient processes. Offering a one-stop solution from prototyping to large-scale production, they eliminate the headaches caused by fragmented operations and coordination challenges.

Mastars has reimagined supply chain management with a fully integrated model that removes the need for juggling multiple suppliers. Instead of dealing with various vendors scattered across different locations, clients partner with Mastars as their single manufacturing hub.

This unified approach ensures real-time coordination and a smooth flow of data, simplifying logistics for Australian manufacturers. By keeping everything under one roof, Mastars not only reduces delays but also ensures consistent quality throughout the process.

Quality control is at the heart of Mastars' operations. Using Industry 4.0 technologies, they identify potential quality issues early in the production cycle, preventing minor problems from escalating into major setbacks.

Continuous monitoring ensures that every stage of production - from initial prototypes to mass production - meets strict quality standards. As production scales, automated inspection systems take over, offering precise and consistent checks. This frees up skilled workers to focus on refining processes, making the entire operation more efficient.

Unexpected equipment failures can bring production to a grinding halt, but Mastars has a solution. Their predictive maintenance systems use real-time data analytics to track equipment performance and flag potential problems before they cause breakdowns.

By scheduling maintenance proactively, rather than reacting to emergencies, Mastars minimises disruptions and keeps production on track. Automated monitoring of performance metrics across all machinery ensures maintenance is planned during optimal windows, cutting downtime and lowering maintenance costs.

Clear and consistent communication is another cornerstone of Mastars' approach. Their integrated communication platforms connect internal teams with clients, ensuring everyone stays informed throughout the production process.

Issues are quickly identified and addressed through robust feedback systems, allowing process improvements to be implemented without delay. With standardised communication protocols and a centralised system, design changes or modifications are handled swiftly, reducing complexity and saving valuable time during production.

Even the most advanced manufacturing systems require regular evaluation to stay efficient. Mastars supports Australian manufacturers by refining production timelines through a data-driven approach. This aligns with Mastars' integrated manufacturing strategy, ensuring every production step hits its efficiency goals.

Mastars leverages performance metrics from every stage of production to identify bottlenecks and inefficiencies. By comparing cycle times to industry benchmarks, they can quickly spot deviations and take corrective action.

A detailed root cause analysis uncovers the sources of delays and evaluates their overall impact. This structured, measurable approach ensures that improvements are precise and focused on enhancing production timelines.

These insights pave the way for immediate and effective process adjustments.

Using the data gathered, Mastars integrates ongoing feedback into its process improvement efforts. Regular reviews and feedback sessions help teams refine operations and eliminate unnecessary steps. By following a clear process - identifying issues, exploring solutions, testing changes, and monitoring results - Mastars ensures that adjustments deliver the desired outcomes.

Collaboration across different teams plays a key role here. Sharing insights among departments often leads to practical changes that boost overall efficiency.

Strong communication is just as important as data analysis in evaluating production timelines. Mastars uses clear, localised reporting formats (DD/MM/YYYY) to keep stakeholders updated on milestones, progress, and any required adjustments. Regular reports summarise completed tasks, outline upcoming goals, and highlight potential risks.

Proactive communication is also a priority. Open and timely dialogue keeps everyone on the same page, fostering a collaborative environment that supports efficient production processes.

Post-production delays can quickly turn profitable projects into financial headaches for Australian manufacturers. Issues like supply chain disruptions, quality control problems, equipment failures, and inefficiencies in manual processes often derail timelines and budgets.

These challenges are compounded by technical hurdles such as fragmented supply chains, difficulties in scaling operations, and limited automation. To tackle these problems, Mastars offers a comprehensive manufacturing strategy designed to streamline workflows and deliver consistent, reliable results.

Mastars takes a proactive approach with end-to-end integration, advanced quality controls that minimise the need for rework, and predictive maintenance systems to reduce downtime. Their focus on clear communication and timely feedback helps identify and resolve potential issues before they escalate.

What sets Mastars apart is their emphasis on data-driven continuous improvement. By leveraging performance metrics and providing transparent, locally formatted reporting, they ensure measurable gains in efficiency. This analytical approach forms the backbone of Mastars's strategy for enhancing post-production processes.

For Australian manufacturers, Mastars's one-stop solution eliminates unnecessary handoffs and communication gaps, leading to faster project completion and consistent, high-quality outcomes.

Australian manufacturers face unique challenges due to the country's geographic isolation, but there are ways to address these effectively. One key approach is to diversify supply sources while boosting local production. This reduces dependence on imports and lowers the risk of being impacted by international supply chain disruptions.

Another smart move is creating strategic reserves of essential materials. Combined with making the most of regional trade agreements, this can strengthen supply chain resilience. Additionally, investing in digital supply chain technologies offers better visibility and flexibility, helping businesses respond faster to disruptions and plan more effectively for Australia's distinct logistical hurdles.

Integrating predictive maintenance into manufacturing processes offers a range of benefits that can transform operations. For starters, it can cut unplanned downtime by as much as 50%, keeping production lines running smoothly and minimising disruptions. On top of that, it can increase equipment lifespan by 20–40% and lower maintenance expenses by 18–25%, delivering noticeable cost savings.

By detecting potential problems early - before they escalate - predictive maintenance boosts both productivity and reliability. This approach not only ensures consistent manufacturing performance but also supports timely delivery of products and more efficient use of resources.

Mastars employs a forward-thinking approach to quality control with its quality management system (QMS), focusing on standardised processes, automation, and ongoing improvements. Unlike traditional methods that often rely on manual work and inconsistent records - leading to potential delays and mistakes - Mastars' system is built for precision and efficiency.

By leveraging automation and advanced data handling, their QMS ensures consistent adherence to regulatory standards, minimises errors, and boosts operational efficiency. The result? Higher product quality and faster response times, enabling Mastars to seamlessly meet customer demands while staying compliant with regulations.