Cable harness assembly is critical for ensuring the reliability of consumer electronics. Poor quality can lead to device failures, safety risks, and costly recalls. To maintain high standards, manufacturers must focus on:

Adhering to established industry standards is the backbone of dependable cable harness assembly. These standards provide manufacturers with clear guidelines on materials, processes, and quality control measures, ensuring consistent performance across diverse applications and environments. Compliance also promotes seamless interoperability between components from various suppliers, making integration with other electronic systems straightforward. Mastars incorporates these standards at every stage of the manufacturing process.

Some of the key industry standards include:

At Mastars, quality is at the core of everything we do. We meticulously align our practices with these essential industry standards, applying stringent quality control measures throughout our operations. By continuously refining our processes, we ensure that every cable harness assembly not only meets but exceeds international standards, solidifying our reputation for delivering reliable and high-quality products.

The backbone of a dependable cable harness assembly is the quality of its raw materials and components. Every component must pass rigorous checks to meet strict specifications before it enters the assembly line. This verification stage acts as a critical safeguard against potential system failures that could jeopardise the integrity of the entire electronic setup.

Material verification isn’t just about a quick visual check. It involves detailed testing and thorough documentation to ensure that each component can handle the electrical, mechanical, and environmental demands it will face. Using subpar materials can lead to connectivity problems or even complete system breakdowns.

A robust material verification process evaluates several key attributes for each type of component. For wires, this means confirming the correct gauge to ensure they can handle the required current and maintain voltage stability. The conductor’s purity is also assessed to ensure it meets established standards. Insulation materials are scrutinised for their dielectric strength, temperature tolerance, and chemical compatibility with other assembly elements.

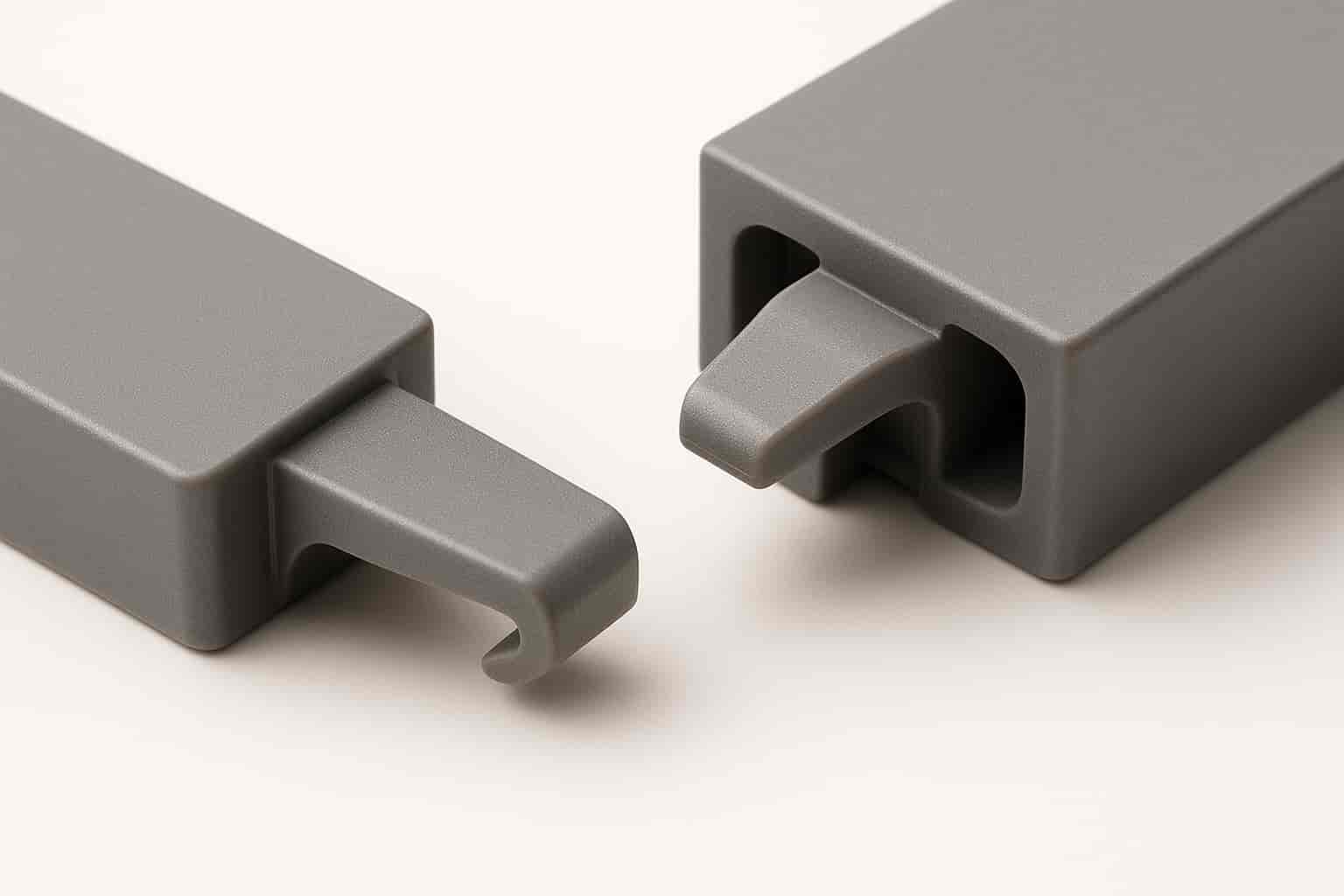

Connector verification focuses on ensuring precise dimensions for proper mating with counterpart components. The plating thickness and material composition of contacts are checked to guarantee reliable performance and resistance to corrosion. Additionally, the connector housing must demonstrate adequate mechanical strength and resilience to environmental factors.

For terminals, the process involves verifying material composition, plating quality, and dimensional accuracy. The crimp barrel must match the wire gauge, and the contact areas should ensure secure and lasting connections. Spring tension testing in female terminals ensures consistent contact pressure over their expected lifespan.

Insulation and protective materials - such as cable ties, heat shrink tubing, and protective sleeves - are also crucial for durability and safety. These materials undergo testing for flame resistance, chemical compatibility, and temperature stability to ensure they meet performance requirements.

At Mastars, we use advanced testing equipment and follow detailed, documented procedures to trace every component batch from the supplier to the final assembly. We maintain meticulous records, including material certifications, test results, and supplier qualifications, to ensure full accountability across our supply chain.

Once materials are verified, they are tracked throughout the production process, ensuring that every component’s journey is fully documented.

Component traceability has shifted from being a quality assurance measure to becoming an essential business practice. It plays a key role in reducing risks in consumer electronics by enabling the precise identification of defective components or batches, which supports targeted recall actions when necessary.

Modern traceability systems, such as Digital Twins and Manufacturing Execution Systems, enhance this process by documenting both product and process histories. These tools help monitor, control, and record every step of production.

Technologies like barcodes and RFID systems assign unique identifiers to components, materials, machinery, and workstations. This allows for detailed logging of process parameters, such as crimp force, tool changes, and quality test results, all with accurate time stamps to create dynamic trace records.

At Mastars, we’ve established comprehensive traceability protocols that document the origins of components, processing details, and assembly sequences for every cable harness produced. Our digital systems ensure that complete assembly data is accessible throughout the product’s lifecycle, helping us meet regulatory requirements, resolve quality issues, and manage recalls efficiently.

Maintaining strict controls at every step of the assembly process is essential to ensure consistent quality and minimise defects. These controls cover everything from workstation setup and tool calibration to managing environmental conditions and workflows. By creating a structured and well-regulated production environment, manufacturers can achieve reliable and high-quality output.

Modern cable harnesses are intricate and require precise oversight of assembly parameters. Factors like temperature, humidity, and other environmental conditions play a significant role in connection quality and the overall durability of the product. Effective process controls monitor these variables, keeping them within specified limits throughout the production cycle.

Proper wire routing is a cornerstone of quality assembly. It ensures wires avoid interference and mechanical stress by following designated paths that steer clear of sharp edges, moving parts, and heat sources. This process begins with careful planning, accounting for wire lengths, service loops, and strain relief needs. Each wire is positioned strategically within the harness bundle to maximise electrical performance and mechanical reliability. To simplify the process, colour coding and numerical marking systems are used, helping operators accurately place wires.

Crimping is another critical step. It must be precise, with close attention paid to factors like force, dwell time, and tool positioning. A well-executed crimp creates a gas-tight seal that prevents corrosion and ensures strong electrical conductivity.

Strain relief is essential for protecting connections from mechanical stress, which could lead to intermittent failures or disconnections. The method of strain relief depends on the specific connection point and factors like movement, environmental conditions, and space limitations. Common solutions include heat shrink tubing, cable ties, and moulded boots, each chosen and applied based on the assembly's requirements.

At Mastars, we follow standardised work instructions that outline every step of the assembly process. These include tool settings, quality checkpoints, and handling procedures. To minimise human error, we use poka-yoke (error-proofing) techniques, such as colour-coded connectors and fixtures designed to prevent incorrect assembly. These measures not only enhance quality but also maintain production efficiency.

Our production lines are equipped with real-time monitoring systems that track critical parameters like crimp force, torque values, and cycle times. If any parameter deviates from acceptable ranges, the system immediately alerts operators and can pause production to prevent defective assemblies from moving forward.

Of course, even the most precise methods depend on skilled operators to uphold these standards consistently.

Strong process controls are only half the equation; skilled operators are equally important to achieving high-quality results. At Mastars, we’ve developed a multi-tiered training programme that combines theoretical knowledge with hands-on practice. Operators are certified only after demonstrating their proficiency through assessments and regular performance reviews.

Hands-on training is particularly valuable, as it helps operators develop the muscle memory needed for tasks like consistent crimping, proper wire handling, and efficient assembly techniques. New team members learn by working alongside experienced operators, ensuring that best practices are passed down while maintaining high-quality standards.

Our certification programmes ensure operators are fully competent in their roles. These programmes include written tests, practical demonstrations, and ongoing evaluations. Operators must prove their skills before working on specific product lines or performing critical assembly tasks.

To stay current, we prioritise continuous improvement initiatives. Regular refresher sessions address common quality issues, introduce better assembly methods, and keep operators informed about new materials and techniques. We also value operator feedback, as those on the front lines often provide valuable insights into improving processes.

Through cross-training programmes, we cultivate versatile operators capable of working across multiple product lines. This adaptability helps maintain production schedules and ensures consistent quality, even during staffing changes or shifts in production demands.

Finally, performance monitoring plays a key role in maintaining high standards. Metrics such as defect rates, rework needs, and productivity levels are tracked for each operator. This data highlights areas where additional training may be needed and recognises top performers who can mentor newer team members. Comprehensive training records also support quality assurance and ongoing improvement efforts.

Inspection and testing are essential steps in ensuring the reliability of cable harnesses. These processes confirm that every assembly meets the necessary electrical, mechanical, and safety standards before reaching the customer. Skipping thorough testing can result in minor defects that escalate into field failures, expensive recalls, and harm to a company's reputation.

Cable harnesses are critical in consumer electronics, where failure can go beyond inconvenience and pose safety risks. That's why testing needs to be methodical, repeatable, and capable of identifying both glaring issues and subtle problems that might surface under specific conditions. A multi-layered testing approach, addressing potential issues at different stages, is far more effective than relying solely on a final inspection.

Environmental factors also significantly influence testing outcomes. Variations in temperature, humidity, and electromagnetic interference can skew results. Maintaining stable testing environments and using calibrated equipment ensures accurate and consistent measurements.

Continuity testing checks the basic electrical functionality. This test ensures that electrical paths exist where they should and are absent where they shouldn't. Advanced testers can even detect intermittent connections under stress. A low voltage is applied across each circuit, and resistance is measured, with acceptable values typically ranging from 0.1 to 5.0 ohms, depending on the wire gauge and connection type.

Insulation resistance testing helps prevent short circuits and ensures long-term reliability. This method applies higher voltages - usually between 500V and 1000V - between conductors and from conductors to the ground. Insulation resistance values generally need to exceed 10 megohms, though specific requirements depend on the application and environmental conditions. Sustained voltage testing can uncover hidden insulation flaws.

Pull testing evaluates the mechanical strength of connection points. Crimped connections are subjected to axial pull forces ranging from 10N to 200N, depending on the wire gauge and connector type. The connection must retain electrical continuity throughout the test and show no visible damage. Specialised fixtures apply axial force without introducing side loads.

High-voltage testing (hipot testing) exposes insulation to voltages much higher than normal operating levels, typically between 500V and 4000V for durations ranging from 1 to 60 seconds. This test identifies insulation weaknesses that might not be evident during regular operation but could cause failures over time.

After these tests, in-process and final inspections ensure the assembly meets quality standards.

At Mastars, we use automated test equipment and integrated quality control systems to maintain uniform test conditions. Our systems can run multiple tests simultaneously, testing up to 1024 points in a single setup. This not only reduces testing time but also improves accuracy by eliminating human error in test setup.

Environmental stress testing pushes assemblies to their limits with temperature cycling, vibration, and humidity exposure. Temperature cycling between -40°C and +85°C highlights thermal expansion issues, while vibration testing at frequencies up to 2000Hz uncovers mechanical weaknesses. These tests often run for extended periods, simulating years of use to reveal potential ageing effects.

These rigorous electrical and environmental tests lay the groundwork for consistent in-process and final inspections.

Once automated tests confirm the assembly's electrical and mechanical integrity, detailed inspections ensure consistency throughout production. In-process inspections are designed to catch defects early, when fixes are less costly. These inspections occur at specific points during assembly, focusing on irreversible steps like crimping, soldering, and overmoulding. Inspectors follow documented procedures with clear acceptance criteria for each stage.

Visual inspection remains a cornerstone of quality control, even with advances in automation. Trained inspectors carefully examine crimp quality, wire routing, connector alignment, and overall workmanship. They look for issues such as damaged insulation, improper strain relief, contamination, or signs of mechanical stress. Tools like magnification equipment and good lighting help detect subtle flaws that automated systems might overlook.

Dimensional verification ensures the assembly fits its intended application. Key measurements include overall length, branch lengths, connector positions, and bend radii. Complex assemblies may require precise measurements using coordinate measuring machines (CMMs), while simpler fixtures are sufficient for standard products.

First article inspection is critical for validating new products or process changes. This comprehensive check evaluates every aspect of the assembly against engineering drawings and specifications. It includes electrical testing, dimensional verification, material checks, and workmanship evaluation. Production only begins once the first article inspection is fully approved.

At Mastars, our quality control systems monitor inspection results in real-time, enabling immediate responses to quality trends. Statistical process control charts help identify when processes begin to drift, allowing for corrective action before defects arise. Inspection data is also fed back to process engineers to support ongoing improvements.

Final inspection serves as the last checkpoint before shipping. This step combines automated electrical testing with detailed visual and dimensional checks. Each assembly receives a unique serial number, linking it to complete test records and ensuring traceability.

Sampling plans are used for high-volume production to balance inspection costs with quality assurance. Statistical methods determine inspection frequency, ensuring quality without unnecessary delays. Critical aspects are inspected 100%, while less critical features may be sampled based on process capability.

Our inspection equipment is regularly calibrated to maintain accuracy. Calibration schedules adhere to international standards, with certificates traceable to national measurement benchmarks. This ensures consistent and reliable inspection results, reinforcing both quality assurance and customer trust.

At the heart of our assembly controls and testing protocols lies a commitment to thorough documentation. This isn't just about ticking boxes for compliance - it's a critical tool for maintaining quality and ensuring accountability. Without detailed records, identifying root causes or meeting regulatory demands becomes a daunting task. Documentation acts as a safety net, protecting both manufacturers and end users.

Modern cable harnesses exemplify the necessity for precise record-keeping. These assemblies often involve dozens of components sourced from various suppliers, each with unique specifications and quality standards. If a problem arises months - or even years - after production, having detailed documentation can make the difference between a quick fix and a costly, time-consuming investigation.

Regulations across industries reinforce the importance of documentation. For instance, the automotive sector adheres to ISO/TS 16949, which mandates full traceability from raw materials to finished products. Medical device manufacturers follow ISO 13485, requiring even stricter documentation practices. Consumer electronics often fall under IEC standards, each with its own set of requirements. These records form the backbone of quality assurance processes, as outlined below.

At Mastars, we integrate documentation systems with production equipment to automatically log process parameters and test results. This eliminates manual errors and ensures comprehensive records for every assembly. Our digital tools also maintain version control and allow instant access to historical data.

Traceability ensures every component and assembly step can be tracked, enabling swift action when issues arise. Here’s how:

At Mastars, we use advanced traceability systems to track components from receipt to final shipment. Our databases maintain comprehensive genealogy records, detailing which components were used, when, and by whom. This level of detail allows us to respond quickly to quality issues or regulatory inquiries.

Effective packaging is a crucial step in ensuring cable harnesses stay intact and functional during transit. Without proper packaging, components can fall victim to static electricity, moisture, temperature fluctuations, or physical impacts. The result? Potential failures, warranty claims, and unhappy customers.

At Mastars, packaging isn’t just an afterthought - it’s a critical part of our quality assurance process. From the factory floor to the final delivery, we prioritise packaging that maintains the integrity of every cable harness. Our tailored methods adapt to the specific needs of different applications, ensuring that each product is protected according to industry standards.

Ensuring the quality of cable harness assembly isn't about relying on a single step - it’s about employing a thorough, step-by-step approach that covers every phase of production. From adhering to industry standards at the outset to careful packaging and shipping at the end, maintaining reliability in consumer electronics requires consistent attention to detail throughout the process.

Using verified materials and maintaining detailed traceability ensures that production begins on solid ground. Consistency is upheld through strict process controls and well-trained operators, while rigorous testing procedures catch potential issues before products leave the facility. This proactive approach minimises costly rework and prevents failures, seamlessly integrating into the broader manufacturing framework.

Comprehensive documentation and traceability provide the backbone for accountability and informed decision-making. These records not only enable quick responses to concerns but also drive ongoing process improvements. When paired with robust packaging practices, they form a complete quality assurance system that supports long-term reliability.

At Mastars, this meticulous approach to cable harness assembly reflects our dedication to delivering reliable solutions across a variety of industries. From rapid prototyping to full-scale production, we prioritise quality at every stage, ensuring it’s embedded in the process rather than treated as an afterthought.

Manufacturers of cable harnesses must follow established industry standards to guarantee both quality and reliability. A key guideline in this field is the IPC/WHMA-A-620 standard, which specifies the requirements and acceptance criteria for cable and wire harness assemblies. Meeting this standard ensures that products are built to high-quality levels and are safe for use in areas like consumer electronics.

These standards play a vital role in minimising electrical failures, ensuring consistency in production processes, and complying with safety regulations. Adhering to them not only helps manufacturers meet regulatory expectations but also strengthens customer confidence - an essential factor for sustaining success in this competitive industry.

Mastars takes quality and accountability seriously in cable harness assembly by implementing strong traceability systems. Each cable is carefully monitored throughout its journey - from production to final assembly - ensuring complete transparency at every step. This approach also confirms the authenticity of components, reducing the chance of counterfeit parts slipping through.

On top of that, Mastars keeps detailed records for every stage of the assembly process. These records not only ensure compliance with industry standards but also serve as a dependable resource for quality checks and future needs. With a focus on precision and accountability, Mastars consistently provides reliable, high-quality cable harness solutions.

To excel in cable harness assembly, operators must be well-versed in reading and interpreting technical drawings and wiring diagrams. This skill is essential for ensuring accuracy throughout the assembly process. Additionally, operators require exceptional manual dexterity and attention to detail to work with delicate components and guarantee the reliability of the final product. A solid understanding of hand tools and assembly techniques is also a must, along with basic mathematical abilities to perform precise measurements and calculations.

Regular training on industry standards and best practices is key to maintaining high-quality work and keeping up with advancements in technology. When combined with a strong emphasis on precision and consistency, these skills are fundamental to producing reliable and effective cable harness assemblies.